All Activity

- Past hour

-

Float level advice, please.

I think my tab looks too much like a hump, so what happens is the bowl is filled to almost the right level, viewed from the nozzle. I bend the tab down slightly to allow a bit more fuel to flow and it overflows. I think the shape needs to be more of a ramp than a hump, I think what happening, the float gets to almost the right level, I bend the tab down a bit and suddenly the bowl over flows. I think the needle valve goes over the hump. I'm going to try to slightly straighten out the curve. My email is emptech@surewest.net I read it often, don't see this site all the time. Jim

- Today

-

Seppi72 started following [2025] What Did You Do To/with Your Z Today?

-

[2025] What Did You Do To/with Your Z Today?

Today, I tried to install the rear hatch glass in my 240 all by myself. BIG MISTAKE. Even though the glass and weatherstrip sat in the channel OK, I simply could NOT get the inner channel to slip over the weld flange, resulting in an adhesive mess. Then spent two hours with paint thinner and a LOT of rags to remove that black adhesive first from my orange metalflake paint and then from the weatherstrip and its flange channel in an attempt to salvage it for another try when I have an assistant to press down on the edges AND the temperature is at least 65 F. That may not be until next spring. SIGH. Maybe I'll bring my set up into the house and do it in my family room AFTER I put down a big plastic "drop cloth." BTW, the hatch was secured to each of those stands so it would not shift or fall. I was following the procedure outlined by Wick Humble in his book How to Restore Your Datsun Z-Car by placing screen spline in the weld flange channel and then laying in a continuous bead of adhesive over top of it. But, with the glass/rubber assembly not sitting low enough in the hatch opening all I managed to do was get adhesive everywhere it should NOT be -- including me. Oy. So, in the end, I did replace all my OEM incandescent taillight bulbs and my choke light with LEDs that came in today from Super Bright LEDs in California. Cold comfort, but progress.

-

DeeCee joined the community

-

My two swiss S30Z Fairlady Restoration build thread

Recently I got two set of two of the missing Pieces from my 240Z toolbox. I had a set which fit the image, but had different part numbers. Funny enough, now i have three different sets, all have slightly different shape or surface. some have different numbers, but appear to be for the same purpose :-) Despite being a bit corroded, i have at least now another missing piece of the puzzle. Thanks a lot to @26th-Z for your support! I had some free time, so i decided to get some small stuff done on the car. First thing to check off was test-fitting the headlights. Luckily, I always have a range of NOS and used parts on hand. I usually try to use old parts for test-fitting, so I don't mess up new parts, but in this case the old ones weren't really usable. So here we go: NOS headlight buckets and chrome rings, with reproduction rubbers (I will use the NOS set for the final assembly). And installed. You got to love the factory stamps on shiny plated parts. As usual, all bolts are temporary only for the mock-up. For the final assembly, I will use original fasteners :-) I wasn't first sure if the order of the assembly was correct, but it appears it is. And the frog got some eyes, again :-) Next was this choke assembly reinforcement plat made out of hardened plastic: As the name suggests, it's there to reinforce the choke assembly, which is usually mounted on the inside of the center console, and can get a bit wobbly. With this plate, it's instead mounted on the transmission tunnel and way more stable. It's one of these (invisble) improvements of the car, which I think really give the car a better feel. It's quite tricky to place correctly, though. But luckily I had a few completely broken center consoles, so the easiest way was just to drill the holes through the console And then sandwich it all together for test fitting. I also installed an old ashtray just to see if it all still works correctly. Now with the holes on the transmission tunnel. I will not use the original sheet-metal screws but instead have nuts welded on the outside and use machine screws, so it looks like it's a factory thing, from the outside. And the interior mock-ups are coming along. Driver side seat rail, passenger side footrest and center console (With choke assembly) is installed and looks good. Ignore where the choke wires go. They're just there for easier installation.

-

DVNT joined the community

-

240 with e12-80 plug gap

Are you talking the old knee... 😁

-

w3wilkes started following 240 with e12-80 plug gap

-

240 with e12-80 plug gap

I'm with you on older is better but when my "newer" "fireball" coil goes to sh**...I'll be walking home on my brand new artificial knee. I ran the old one for 55 years and that SOB just quit.

-

240 with e12-80 plug gap

Maybe your cables are to old? They get little cracks inside (after you took them off) and the resistance changes to too high? Also use some fresh gasoline because todays fuel is really... sh*t.. I always now use 96 overhere.. my 240z runs 15! km/hr faster on the good stuff! And no problems with older fuel.. (Yeah i know you don't have 96 fuel but your country has different numbers, just use higher number in cars that don't drive daily. No ballast resistor... could make that new coil to hot? The old stuff gone, haha, i drive a 240z with a 54 year old coil, it's still running strong.. in the WINTER it's my daily driver! Lastly, i don't know the "newer" stuff like those "fireball" stuff but i don't ....... wouldn't want that sh** under MY bonnet.. oh sorry.. HOOD! ;-) 😆

-

mallory unilite distributor fails when hot

Glad to here that my suggestion hopefully was given some thought.

-

mallory unilite distributor fails when hot

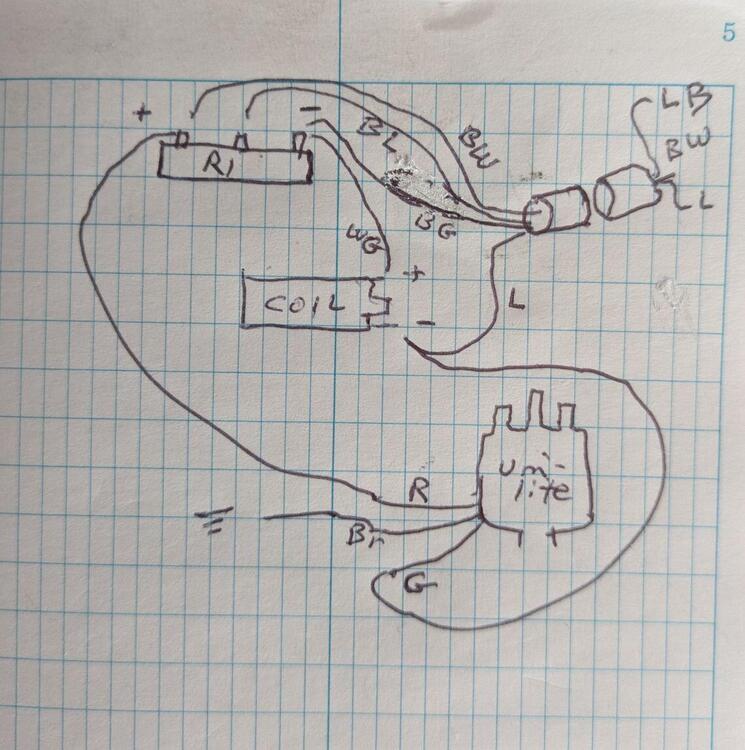

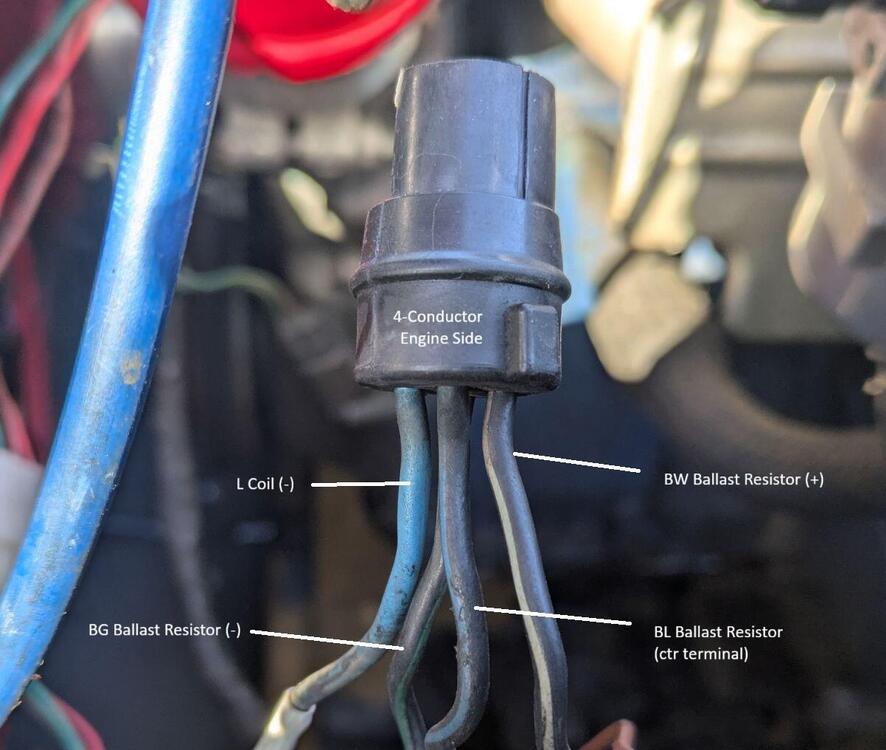

Excellent! Glad it's working. And I agree with the assessment that it was either the second ballast resistor or just a bad connection. And the schematic sketch you posted looks good. It's the same thing as suggested earlier with the inclusion of the tach (blue) wire connection. Glad that worked out as well!

-

Z's on BAT and other places collection

Someone is going to get a good buy. With the insignificant defects, half of the bidders will be scared off.

- Yesterday

-

240 with e12-80 plug gap

Walter Moore is the one that did the work. Distributor advance curves revision 1-2.xls

-

240 with e12-80 plug gap

Everything looks good. I just need to start over with the basic tune up. The dizzy I have says 17 and 34 with full advance. I used that excel spreadsheet someone made for all the distributors. My markings show it to be a '79 dizzy. It's ran great until I pulled the plugs and "cleaned them". The car has sat since my knee surgery almost a year now. I haven't done anything since but trying to get back to normal but I admit my priorities have changed. I'm going to get a set of bpr6es and leave that big ZX gap out of it. I read a pretty sensible thread on keeping the gap to the head not the distributor. So I'll try .035 to start then see what that does. I know carbs need protruding tips so I'll go with that. Thank you for the help!

-

1975 280z Build

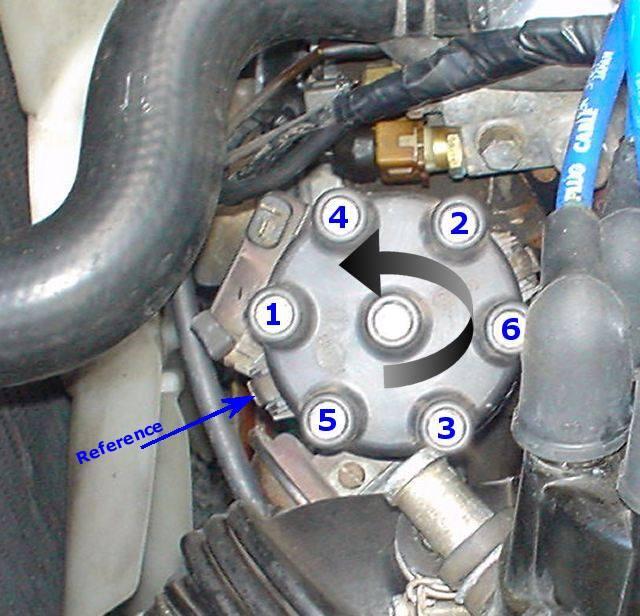

You can check fire at each plug with a 12v light but before that you should make sure the firing order is right. 153624 which is not the same as a straight 6 Ford or Chevy.

-

240 with e12-80 plug gap

What's the tach needle doing when it's missing? Those E12-80's are all old, or if they're not they're probably aftermarket. Maybe it's failing.

-

Z's on BAT and other places collection

Here's one I do not recall seeing posted yet. https://www.hagerty.com/marketplace/auction/1970-datsun-240z/6GCpSGa9ml7BRIZZCDBmQ3

-

1975 280z Build

You have quite a bit of work ahead of you still. Before you put a battery in it and connect it up take a meter and check for resistance between the negative and positive posts. If you have a short there will be very little resistance. Get the wiring sorted out before even installing a battery. Also, just a seed for future thought, be very careful that you know which cable is positive and which is negative. Nissan used black for both. Not uncommon to fry electronics on these old EFI Z's with a backward hookup. Looking at this mess it looks like the PO was trying to solve a problem or was getting ready to part things out. .

-

1975 280z Build

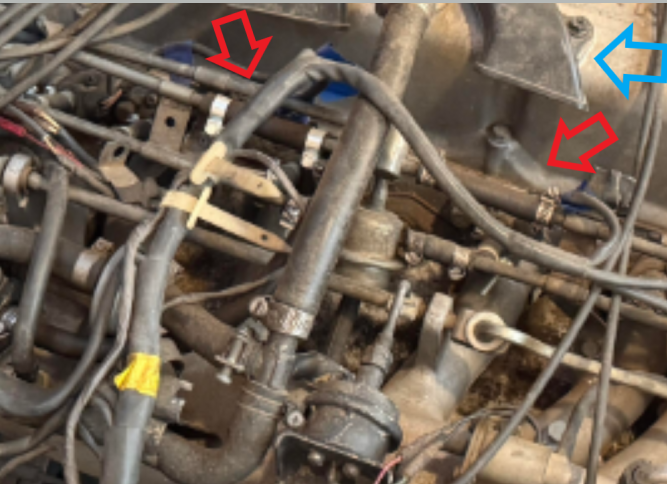

Probably want to check all of the air intake ductwork up to the throttle blade for mouse habitation before using the starter to spin the engine. The air filter box opens with the wing nuts. The AFM hoses need to have the clamps loosened. The hoses can be pretty stuck, you might want a thin screwdrive or a pick to work between the rubber and metal to break them free. Probably need to remove the AFM if you want to get the hoses off completely. The wire clip on the connector can be difficult. Also, check those fuel hoses. Looks like a PO has already fixed one. And the hoses to the injectors. Once you crank up the fuel pressure you'll know more. Might as well get a gauge also to check pressure and pressure dropoff. It will tell you if the regulator is blown out or the injectors are leaking or the check valve in the pump is shot. All common issues after sitting. That pump is probably shot just based on its appearance. The engine looks about ready to go. You'll want to check power to the coil and verify that the original 1975 electronic ignition module is intact, by the fuse box. They fail often. Open up the distributor and see if the bushings are shot. See if the vacuum advance and mechanical advance mechanisms are free. If they're not, don't force them, they can be saved with careful lubrication and disassembly but if you force a rusty mechanism the plastic ball brearing frame will break. I'd check the distributor before starting the engine, even the normal forces can probably break a stuck distributor. Ignore the blue arrow. I was going to mention the ZX fan but already did.

-

SN 00042 Restoration; The Older Twin

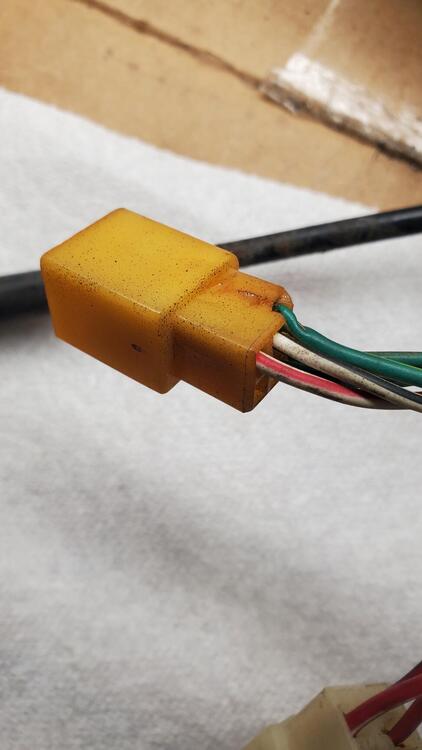

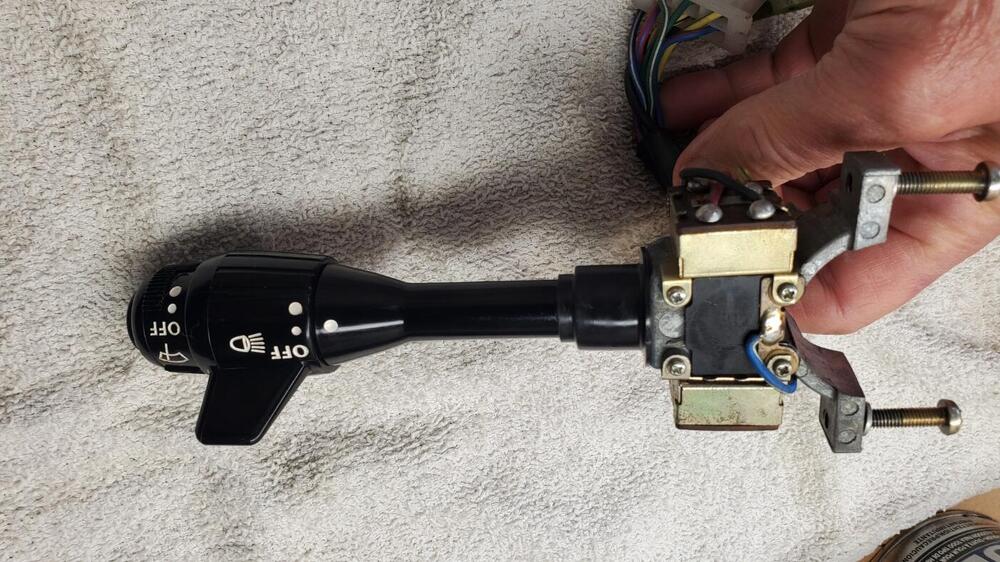

The body shop work continues and looks like things are moving along nicely. I am happy to see that they are being very thorough and even cleaning up areas that no one will ever see. I did check the seat mount locations. The rear inboard bracket on both the drivers and passengers side is off by about 2 inches (both are too far outboard). Carlos has a welder and will do the re-mounting of the bracket. I did contact Larry, the original metal work guy, to point out the error. Looks like we will get that re-mounted for no additional cost. I also sent pics of the dimesnions from the seat rails. The dimensions that I measure are 13.0" wide (330mm) and 12.75" deep (324mm). I removed the air galley from the exhaust manifold, but was not able to salvage it. After repeated heating, cooling and lube applications, I was only able to get 2 of the fittings out. By this time, the hex portion of the remaining fittings were starting to get pretty trashed, so I ended up cutting the tubes on the remaining 4. Fortunately, I did not have to do any re-tapping of the four difficult fittings. I was able to drill away most of the metal in the center of the fittings and sort of peel the threads off of the manifold. This made is easy to save the extension tubes that are secured by the fittings. On all of the previous cars that I have restored, I have always used a gray powder coat finish on the exhaust manifold that Les Cannady at Classic Datsun Motorsports always uses. Since we want to be very exact on the reproduction, I was considering a high temp cast iron paint which would be closer to the original color. However, it was noted that those typically peel even with the best prep and application. POR 15 was recommended, but again, this ends up being a colored paint and softens the texture of the original cast iron and doesn't really replicate the original color. I eventually phoned Rod Schmitt of Rod's Garage (Restorer of the 2025 JCCS Best of Show Red 240Z and John Morton's 1st place Green 240Z in the 240Z category) to find out what he uses for the final finish on the exhaust manifold. Rod says he cleans the manifold well with wire wheel and then uses a couple light coats of graphite spray for the final finish. He says this comes the closest to the original color and finish. It also handles the high temps well. So, this is the current plan for the exhaust manifold finish. I have started cleaning up some of the steering column parts. Some before and after pics are attached. It looks like these components have been accessed previously as the turn signal mechanism had a wire that was just twisted together with an extension on the horn circuit, so I removed the extension and soldered the wire in place. It has a broken connector which I thought I could replace with another signal mechanism that I have but that replacement was just as brittle as the broken coneector, so I just ordered a new one. Also, the headlight mechanism looks surprisingly good, so I am thinking that may have been replaced as it looks virtually brand new. Typically, these are pretty gummed up and the white parts are yellowed and/or dirty. This one looks untouched. I will re-restore the steering wheel as the previous restoration is poor. The black paint is thick and uneven and should be a satin finish, not gloss. The 'wood grain' portion has a heavy gloss finish, should be light satin or semi-gloss, and the back side with the 'nubs' was over sanded so the wood grain appearance is missing on the nubs.

-

1975 280z Build

So got out there yesterday and today for a little bit. Pulled the valve cover and dumped some oil everywhere. Also decided to pull the cooling fan and shroud so I could have access to the front of the engine a little better. I cranked the engine over by hand and felt really smooth. I decided to try the video function of the bore scope and see if I could post it. Mainly wanted to see what the cylinder was doing while I was cranking. I chose cylinder 3 since it was the worst looking. Actually doesnt look that bad. Edit* Appartley this video has to be downloaded, so im uploading to youtube. And lastly, here is a video of the engine cranking over. Sounds like it moves nicely, I hear a little bit of clattering at the end of the cycle. IMG_0026.MOV The borescope is just a cheap Amazon peice. I'm pretty happy with it. I wasnt expecting to use it a lot so I didnt want an expensive one. If I had to do over again, I might look into a four way articulating. The two way is fine, just have to twist the spine to get it where i want. Amazon Teslong Bore-scope While I was at it, I also checked for spark. I have none. Something about this was mentioned when I bought it, but I thought it was just one cylinder. The fuel line was diconnected 'just in case' I know the fuel is bad and the car also came with a new fuel pump. I need to rewatch one of the new 'roadkill' episodes they put out recently to test a coil. I think they are trying to revive the roadkill format via their respective youtube channels. They put out a 4h long episode on Rotsun between the two of them. I could totally just google, but where is the fun in that. Shameless promo, cause this is the car and show format that made me want to get a project. I really enjoy the problem solving.

-

mallory unilite distributor fails when hot

Sorry for the delay in getting back to this. I'm working out of town and only have weekends to visit my car. I think the problem may of been resolved or at least I can drive the car for more than 1/2 hour without the ignition failing. It must of been that extra ballast resistor or a high resistance from the taped splice. The car has been working for 7-8 years and only periodically had ignition issues so I'm assuming one or more weak links in the ignition began to fail. Here's the wiring as it stands now. Some of the colors were hard to see until I cleaned the wires off with solvent.

-

Z's on BAT and other places collection

This is a nice car and you can see it's well taken care of. I wonder if the dad was a member of this club.

-

240 with e12-80 plug gap

I'm using a Crane/Fast PS20 Fireball with 1.4 OHM coil, no ballast resistor. I wanted all that old stuff gone, I've never fooled with points except file down the contact point on my go-kart. Cool little file too. It starts missing with the wider gap up high but from what I remember I've always ran the wider gap? Grasping at straws, the easy ones.

-

240 with e12-80 plug gap

Hi, I always use the standard BPR6es-11 on my standard ignition with nos contact points. I think it will depend on what ignition coil your using i would go with the bpr6es-11 sparkplugs when you have a orig. coil. Btw, the 280zx i got has that orig dizzy, and uses also the same plugs runs great with -11 plugs. (1,1 mm Gap.) You could buy those 0,9mm plugs and if it does not run right open them up to 1 mm or so.. (If you have the 123 ignition coil.. my opinion? throw it in the BIN! and get yourself a orig. coil.. ;-) )

-

dutchzcarguy started following 240 with e12-80 plug gap

-

Z's on BAT and other places collection

Yeah, i don't know about 40k or not. The extensive modifications are breaking my heart. He needs to put it on BaT to know the current value IMO.

-

Peedogg joined the community

- Last week

-

240 with e12-80 plug gap

I have an later e88 with SUs and ZX dizzy, e12-80 on my 240. I've read a lot of different stuff on the plug gap. Half say go with the motor and the other half say go with the ignition. Motor says protruding with .035ish gap. Ignition for '79 says non protruding .044ish gap. I like to think it has the strong spark at .035 protruding for carbs. I opened them up to .042 on bpr6es-11 and it didn't run too good. What do you all think? I also read that a closer gap on the 1.1mm would angle the tip downward too much and you don't want that. I think I should buy these instead of the 1.1mm https://shop.advanceautoparts.com/p/ngk-standard-nickel-spark-plug-bpr6es-reliable-oe-performance-4008/18090163-p?product_channel=local&store=6668&adtype=pla&product_channel=local&store_code=6668&&&&&gclsrc=aw.ds&gad_source=1&gad_campaignid=16396150477&gclid=CjwKCAjw6vHHBhBwEiwAq4zvA_2SIcXPfpN8WAkuS9dMgo6W_K-pa5oGWg56uecTiat8BKKgmfmKTRoCxtAQAvD_BwE Thank you for any input.

-

Z's on BAT and other places collection

It is buy it now for $40k. I told him to emphasize that the original mileage is 51k and to add some pics of his documentation... pics of the various VIN plates and VIN on the firewall, and pics of the engine number on the block and the E31 on the head. I see he has added the documentation and the engine compartment tag already. I know the market is a lot softer now for these than it was, but I think it will sell for the $40k.