Everything posted by EuroDat

-

My two swiss S30Z Fairlady Restoration build thread

Sound interesting. BTW, the front end section doesnt look that bad on the photo. You was planning to replace it with the white one. Are you still going with that idea? Chas

-

280Z Full Restore in 5 months, hopefully.

Im still playing with mine. Not real happy with the gap between the grill and the bumper. I can set the bumper further back to the grill, but then the sides dont line up with the recess in the vender at the wheel arch. Thinking about fitting the trim that covers the cap between the 280Z bumper and the grill. Ill take some photos of my progress so far, which is very very slow compared to you;) Later Ill fit the 240Z air-dam plus indicators, but for now it has the 280Z valences. The original grill under the bumper is way too small and leaves a big gap. You can also try the JDM grill that 1 tuff Z (on Hybridz) made. You can order them via MSA. There is also a thread here about it. You will need to remove the 280Z indicators. Cheers and goodluck. Dry ice has the WOW effect.

-

Time for diff and transmission swap, what more to change?

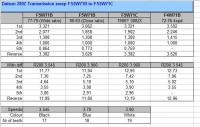

Hi Andreas, It wont be quicker of the mark. The close ratio box with its "taller" first gear defeats the advantage the 3.90 diff will give you. Once your moving its a lot different. The close ratio transmission and the 5th gear with work a lot better. The spred across the ratios is a lot smoother than the overs transmissions. I made a table for my 280Z when I was buzy planning my swap. I added your 4 speed to it to give you an idea what you will end up with. Hope that helps. Chas

-

Time for diff and transmission swap, what more to change?

Your right Zed thanks for the correction, I was thinking of the 71C swap I am planning this coming winter:stupid: I realised it too late and Mike had the website down for maintenance. Chas

-

Time for diff and transmission swap, what more to change?

Hi Andreas, I rebuilt mine transmission last year in the 280Z. It has the ZX tranny and the R200 3.9 ratio. The 71B tranny came in the 280Z and the ZX, but the ZX has a cross ratio version. IMO If your going to dismantle the tranny: - I would at least replace the bearings, O-rings, Lip seals and front yoke gasket. Nissan sells all the parts separatly. You can order a aftermarket bearing kit from the US which is not complete by all means, but its easy to order them at your local bearing supplier. There are some bearings that need to be sourced from Nissan. - The 3 nylon bushes in the selector are a must and make it feel like new. Gets rid of that "stick in the mud" feeling when changing gears. - Replace the shaft nuts (main output shaft is left hand thread). - While its out, good time to check the clutch and replace the release bearing. Your speedo gear should be the right one for that diff, if the diff came out of the same ZX. Depends on your tyre size for true speed readings though. R200 - Rear cover gasket and breather. - Pop the side shafts and replace the seals. - if the pinion seal is not leaking, I would leave it in. You can replace it, but sometimes it will whine after because the pre-load and alignment gets mucked up a little bit. It doesnt take much to start whining and its hard to correct. If you need part numbers, Ive still got my shopping list somewhere and can scan it in if you want it. You will also have to do something about your driveshaft. It will be too long for the five speed. You will need to get it shortened or a series I driveshaft. Goodluck Chas

-

L28 exhaust manifold source

If your looking for one at slavage yards. You should look for a N47 (aug 76 to Jun78). The number is cast into the manifold. The N43 (pre jun 76) has the square ports and would bolt up to the N47 head. The P71 manifold is for the 280ZX. Goodluck Chas

-

71' Refresher project starts

You have done a good job mounting the intercooler. Looks really neat.

-

Fairlady Grill Reproduction

Yes thats 1tuff Z's grill he made in the Hybrids thread. He produced two series of 10 and is now selling through MSA. I posted in the thread enquiring about the 280Z. He was buzy with a friends 280Z, but it used the original valences and Im using the PU Air-dam from MSA so Im sort of a crossing between the two. Tamo3 had he same problem with his 280Z and would have to do some mods to get it to fit. 1 tuff Z very sporting and refund him no problems. Its still tempting to try. It looks great Chas

-

Dropping 83 ZX Motor Into My 77 Z

It seems you guys covered about everything so far except the webbing. The webbing was introduced as a heat shield and replaced the metal plate under the inlet manifold. The inlet manifolds N42, N43, N47 (208Z manifolds) and U87 280ZX all flow pretty much the same and you will notice very little difference in that field. The P82 used on the ZX turbo flows marginally better and will bolt onto all 3 NA heads. Chas

-

cool 240z postage stamp

I wonder where the islands imorted the 240Z from or which road regulations they followed. Its RHD, but in Australia they had the front indicator under the bumper and in England they had them in the grill. Chas

-

Progress on rust repairs

Thats great before and after shots on the tank. Never seen a Z tank on the inside. Keep em coming. I had to cut a tank open on a Holden Monaro years ago because the baffle crack off and broke the fuel pick-up. It took some toubleshooting to fique that one out. It had what they called a Bathurst tank and I couldn't find another one. Keep the photos coming. Eccellent thread Chas

-

Gasket for Inspection Lamp

Thanks for the compliments Mike. I like to hobby with this stuff. It all started when I made my euro lenses for the 280Z tail lights. I get the mould done soon and if everything goes well with shipping, I can make some for members. Tomo, The foam materiaal is used by DAF trucks here in Eindhoven and we use it for our HEPA filter ducting. It comes on a 50metre rol and its 5cm wide. I dont have the box it came in, but I can have a look next week. Its probably available in shorter lengths and Im sure the store would cut off a 20cm length for you if you ask nicely. I can also send you a gasket if you want. Chas

-

280Z Full Restore in 5 months, hopefully.

What are your plans for the front grill and bumper? I see your want to remove the 280Z bumpers and just wondering what are your plans for the front. The air dam looks like a 280Z type, I cant see if it has the recesses for the 240/260Z indicators on the photo. So just wondering how you will go about it. I changed my 280Z bumpers to 240Z and still not really happy with the front. I have the PU air dam for the 240Z and the indicators but still looking at ways toget the grill to match the bumper without big gaps. Been looking at modifying the metal shield that fitted behind the bumper and attached to the bumper shocks and front fenders. The other option is to make a new grill. Chas

-

Gasket for Inspection Lamp

I just made some photos of the ones I made some time back. The one I am using in the car is 2 years old and no signs of wear. The rubber foam Im using is used as a vibration insulator in truck bodies so it should hold up to the conditions its in without any problems. The grey/green lens is a 3mm shorter mock up for a new mould. It still needs polishing. The photo doesn't show the height difference all that well, but it is a little shorter. Chas

-

Gasket for Inspection Lamp

I stamped mine out of rubber foam. Its about 3mm thick and works well. Mike, I think the original (on mine) was a silicone rubber gasket with a clear adhesive ring to attach it to the lens holder. The adhesive in mine turned brown and brittle. The silicone just crumbled in my hand. I also made a mould for the lens, but its 2mm to high to send as regular post and therfore cost €16.00 to ship anywhere outside The Netherlands:disappoin Started making a shorter version, but other more important projects keep interrupting planning. Now winter is coming Ill finish it. See blog for details Chas

- Happy to be here

-

280Z Full Restore in 5 months, hopefully.

Your not a Z veteran until you have done spindle pins. They would be up there at the top of the list for worsed jobs you can do on a Z. Your project is on steroids. Hope you can keep it up. What you have done in a couple of weeks would take me like 2 years. Chas

-

Urethane bushings squeaks

I can remember mine being a real pita to get the LCA and PU bushes back on and inline so I could tap the spindle pin back in. Ended up using a paint scrapper to help lever/guide the bush over the stub axle. It was about 2 -3mm too small, but it was new and your situation is has used bushes. The distance between the new ones should be even less. I don't think your problem is here though because you don't have the problem when you torque the nuts. The problem starts when you compress the PU bushes until the washer locks down on the sleeve. I would start comparing things with the drivers side since its working oke. Can you see any difference in height between this and the drivers side? Chas

- fluid specs and capacities for 78 280z

-

Urethane bushings squeaks

Looks like you found your problem. The only way I can think of that wear is the spindle nuts were on tight and the sleeve could spin. Do you have any ideas on how to repair it or are you going to replace the strut? You could get the end machined flat and use an extra hard metal washer to get the original length. Woulb be a good idea to order a new PU bushing set for the spindle pin. Chas

-

Urethane bushings squeaks

The bushing and sleeve in photo 014 dont look right. The PU bush looks like its missing the flange section, but that might be the photo. If the PU bush does not have the flanged section, the sleeve looks too short which will let the washer bind on the lower control arm tube. This is most probably the source of your squeak. Bad news is that you need to remove the spindle pin to get the bushes out. Chas

-

72 240Z Type B Shifter Bushings??

Just repeatings psdenno's comment. I got mine at my local Nissan dealer. 2x Side bushes 32855-H1010 $2.78ea 1x lower bush 32861-N4200 $2.72. Chas

-

Will a T5 Transmission from a 90s Mustang fab into a 72 240z?

The bell housing is different for a start and I am pretty sure the input shaft splines are different which means you would need to fit the mustang clutch disc in your pressure plate. The bell housing is the hard to get item. Without it you need to cut and match bell housing, but if your in for a challenge, it is possible. I have seen a thread for the T6 done that way. Chas

- fluid specs and capacities for 78 280z

-

Urethane bushings squeaks

I cant remember mine being that tight. I could still move it up and down after torquing, but it required a lot of effort. Thats probably were your squeaking is coming from. Is the spindle pin centered in the right spot. Maybe lossen the locking bolt and retorquing the spindle to center it. Worth a try. Torque settings for the spindle are: end nut 54 - 69 ft-lb and the small cotter pin (locking bolt) is 7 - 9 ft-lb. Chas