Everything posted by Captain Obvious

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Oh, and to answer your question "I guess my end question is, how can I tell if this Duralast sensor is NPT or BSPT?" The answer would be "Use a thread pitch gauge". The 1/8 NPT is 27 threads per inch, while the 1/8 BSPT is 28 TPI. The two of them should be easily distinguishable with a gauge because the thread pitch is different. But if you don't have a gauge, you should be able to hold the two threads against eachother (with the teeth meshed with eachother) and see the difference. If the thread pitches are the same, the teeth will mesh perfect. But if the pitch is different, they will not.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

So just make sure I understand everything... You bought an adapter that has female 1/8 NPT threads on one end and male 1/8 BSPT threads on the other end. And the Duralast sensor you purchased threads nicely into the NPT female end of that adapter. Is all that correct? And also, so how does that new adapter fit into the block? Unless I missed something, you didn't mention that.

-

280z Fuel Vapor Canister - How to Fix

Actually that's not exactly the case either... If your cap seals to the can now, you have effectively capped off all the vacuum lines. However, if the cap does NOT seal to the can (which is what I suspect), you have now introduced a vacuum leak of unknown volume when you are at light cruise on the gas pedal. The size of the leak will be determined by how well the plastic cap seals to the canister. And I suspect that cap seal is not that good since you took out the diaphragm material (because it interfered with the screw head). You will get good idle performance because the purge valve is closed, but at partial pedal position, when the purge valve is opened, you may run way leaner than designed. Not a good situation. OK, I think I've given this enough thought for today.

-

Sanity check on dual points conversion

If I understand correctly, your modification should work fine as is and I'm thinking your issues are not (directly) caused by the single point mod. So on the 73 harness, there are two black wires that go to the distributor for the points, right? And you have shorted both of them together and then connected that pair to the single wire coming out of the 72 distributor? If that's the case, it should be fine. But, stranger things have happened. Can you put the original 73 distributor back in just to see if the problem goes away?

-

280z Fuel Vapor Canister - How to Fix

But I don't want to come off as if I'm poo-pooing the idea. I actually think it's a pretty neat concept to a common problem. So... How would you utilize that Dorman purge valve to accomplish what you were trying to do? Take the screw back out and silicone the cap (with no diaphragm) onto the canister so it doesn't leak. Maybe use the original diaphragm along with silicone to help with the cap sealing, but cut a half inch hole in the center of it first. You want the cap to seal to the canister but you do not want the diaphragm to be able to block off the little hole where you had the screw. One other detail is that you have ruined the metered orifice in the canister by running the screw in, so you would need to use the spare can you picked up instead of the one you had the screw in. So bottom line? Replace the can with the spare (with no screw this time) and put the cap on in some fashion such that it completely seals along the perimeter, but cannot and will not ever block off the hole in the post in the center.

-

280z Fuel Vapor Canister - How to Fix

I'm really sorry, but unless I'm missing something, this modification does not work. Sure, it will get rid of your previous vacuum leak, but only because you have effectively plugged all of the hoses. You could have just capped off the vacuum lines at the throttle body and the intake manifold with rubber plugs and the end result would have been the same.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

Here's some info on that topic: https://www.classiczcars.com/forums/topic/67864-ignition-systems-analysls/ It's a little academic (and unfinished), but I find it interesting. Might just be me. In any event, I'm hoping the module issues here with @HusseinHolland resolve themselves easily. We can get into some of the deeper details if they don't.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Glad you got the busted off remnants of the old sender unit out of the block. As for cleaning out the threads... The correct tapered tap would work fine. Two things I would keep in mind though: 1) Any metal you take off runs the risk of ending up in your oil galley. Take appropriate precautions. 2) Since this is a taper thread, any metal you take off will end up in the male stub threading in further before sealing. Don't go any deeper than you really need to. Clean it out... Don't make it bigger.

-

Smoke coming from head light switch

Hahahahahaha!!!!! No, we don't want to see it.

-

Smoke coming from head light switch

Actually I think it was SteveJ that exhibited naked hostility. Zed, You were properly chastised for not knowing enough ways to skin a cat.

-

75 280Z Clock Repair?

Getting back to clocks and such.... @HusseinHolland, did you try reducing the 2M resistance to see if your clock would start without a push?

-

75 280Z Clock Repair?

Haha!! Of course you do! I think I remember seeing them when I was there.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

Quick web search indicated that the Bosch unit is triggered by a hall effect sensor and therefore does not contain the circuitry to deal with the Datsun VR pickup. Bummer. Would have been a neat modification.

-

75 280Z Clock Repair?

-

75 280Z Clock Repair?

Oh, and just to be ridiculous... Here's how I measure capacitance. Put the cap in parallel with a known inductance, hit it with an impulse function, and then simply measure the harmonic response: Little bit of algebra, and you got it!

-

75 280Z Clock Repair?

Geeez Dave!! Who's older? You or that Heathkit?

-

Wiper rebuild

Are you looking for input into how the pieces were machined and constructed, or input into details about the finish applied after construction?

-

75 280Z Clock Repair?

Well I think that leaves you in a not-too-bad spot. If it started all by itself sitting loose with a 9V, but then would NOT start all assembled off the car battery, then that would be more of a problem and mystery. If it never starts by itself but will run indefinitely if given a push, that's easier to deal with. My quick hit "from my armchair" would be to try a slightly lower value resistor in place of the 2 Meg. Maybe try 1.8 Meg instead. Just to test things, you could parallel another high value resistor (like a 2M or 1.8M) across the existing 2Meg resistor. Just clip it across to see if it will start by itself then. If that works, then you could desolder the 2M and replace it.

-

75 280Z Clock Repair?

Did it start by itself on the bench when you had it apart? With a 9V battery?

-

FPR project - cheaper, more available (for a while anyway)

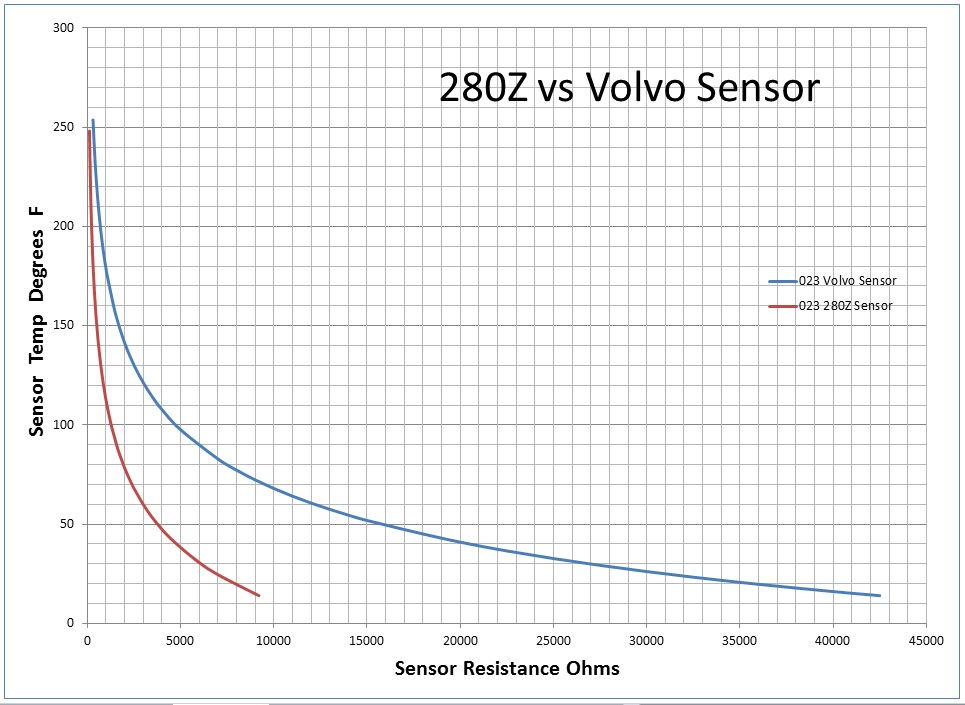

Here's a chart comparing the 023 (Z sensor) and the 028 (Volvo sensor). If you do some water bath testing on either sensor, let me know how the testing compares to the chart:

-

FPR project - cheaper, more available (for a while anyway)

Got it. I will poke around with that data and see what I can come up with.

-

Window crank extension available?

Nice work. I was going to suggest a threaded rod through the center, but I wasn't sure if removing the material out of the center would weaken the shaft to the point of being a problem. If I remember my statics theory, most of the torsional stress should be close to the surface. Couple weld dots and hopefully you're OK.

-

My Datsun 240Z

You need a pair of suspenders for that car now. (Taking a chance that it translates......)

-

FPR project - cheaper, more available (for a while anyway)

I saw those data points. I'm looking for more. With the turn of the page, you maybe missed that clarification?

-

Resurrecting my horn (the sans Viagra thread)

Haha! Honestly, I was just kidding about the whole process. I assumed that the inner cavity never saw any of the de-rusting chemicals. I was poking fun.