Everything posted by Captain Obvious

-

Hatch Lock Button

Why don't you just use a small flat or square file to file the current rectangle to fit ninety-degrees? Like this. Won't be quits as strong as original, but with a washer under the head of the clamping screw, it ought to work:

-

[2020] What Did You Do To/with Your Z Today?

LOL. You guys are fun. Looking forward to the pics! Whatever they turn out to be! Haha!!

-

31K Miles Series I 240Z Up for Auction on BaT - Over $100k on First Day!

Well I got no dog in this fight, but I really don't think that's original paint. There's just too many flags all over the place. In the auction, they never say it has original paint. They do, however, say the following: "The seller reports that a scratch on the right fender and paint chips on the right door were blended in. More than 45 paint-meter readings provided in the photo gallery below show thicker measurements in the aforementioned areas." So what does that mean exactly? To me, that means "We took paint thickness measurements from all over the car and everything looks about the same thickness with the exception of the right side door and fender. Seller reports that those areas were sprayed to fix some issues." I don't think that means the rest of the car is original... All that means is that the rest of the car is CONSISTENT. Like maybe the whole car was sprayed at least once some time in the past, but then the right side was done again? Makes me wonder what the paint thickness would be on a confirmed original paint survivor. Would it be half the thickness they got all over that car? I saw the heater core looped too and I'm guessing the heater core is leaky.

-

31K Miles Series I 240Z Up for Auction on BaT - Over $100k on First Day!

Yeah, that's one of the reasons I'm wondering if everyone is in agreement that it's original paint. It's certainly a beautiful car and I'm no expert on what should/could be painted, but I see stuff that makes me wonder.

-

31K Miles Series I 240Z Up for Auction on BaT - Over $100k on First Day!

Are we sure that is original paint?

-

Opinions on wheels that require hub-centric rings?

I agree with granny above that hub-centric location could/should be more accurate than stud located if the car you're working with was designed to be used in that way. The problem as I see it is... The Z is not designed for that. (Unless you manage to catch the small lip right near the base of the post) the front hubs have that tapered rough cast surface on the center bearing post. That center of the original hubs might run perfect in the center, or it might not. It certainly wasn't machined to guarantee that it would: And the rears have a machined center area, but I think it may be too short to reach deep enough into wheels to do any registration?

-

First start today!

Good pics. I can't tell if the needle depths are spot from just pics, but they look good to me. The typical mistake is that they are installed with no shoulder visible and you do not have that issue. They're at least close, so that's good. As for which needle it is, I think it's worth a phone call. Many people replace the original N-27s with SM needles. Some people end up with great results doing that and others end up running rich with the SMs.

-

First start today!

Yes, the part number is written on the fat end of the needle, and yes you need to pull them out to read them. That said, however... I wasn't thinking you needed to go out and pull the needles right away. I was thinking more along the lines of looking at the literature that came with the carbs from the company that rebuilt them and seeing if there was a listing on there of what needle they used. Failing that, a phone call to the co. would be my next idea. As far as the installation depth goes, you ought to be able to see needle by looking down into the carb throat. Might need a little right angle inspection mirror to see deep enough, but you ought to be able to see if the needles are installed to the proper depth without too much muss/fuss. And if you can't get a good view of them that way, all you have to do is pull the suction cover off and pull the piston out of the carb for a look. Worst thing that would happen is you might have to replace some damper oil if you spill it.

-

1977 280z prepup for smog check

Yes, that's what I'm saying. I have no reason to believe that thing is anything other than a simple pressure (or lack thereof) switch. If it were my car, I would put that device in a jar and try to draw a vacuum on it and see what happened, but if I could not get that to work, I would just short the connections and see what happened. Unfortunately I don't know if you would hear or smell any difference... The effect may be subtle enough that you might only be able to see it with diagnostic equipment.

-

First start today!

So all of that sounds like a significant rich condition. What needles are you running? Stock N-27 or something else? Also, your comment about the needle seating is important... It is possible to install the needles too deep in the suction pistons and if that happened, it can result in a rich mixture.

-

Surprised Nobody Brought Up The Z Proto Reveal

Pics or it didn't happen?

-

First!

Well I'm very glad you're here. Not only because it helps keep you out of trouble, but also because I'm just glad you're here!

-

1977 280z prepup for smog check

About the altitude compensator... All of the documentation I have indicates that the altitude compensator is an ON-OFF switch affair, and not an analog resistance device. I don't have one of those devices here for confirmation, but that's what the docs say. (Ref 77 FSM EF-15 and the 1980 FI bible page 85.) I wouldn't worry too much about a dramatic change in engine operation when the switch changed state. They can handle that in the electronics with smoothing and hysteresis. As for the stuff inside the altitude switch... Don't knock that thing around too much. That "spring" inside is actually a hermetically sealed bellows chamber. It's very similar in construction and operation to the bellows in the throttle pull-pull off and the BCDD. Here's a thread that's about the BCDD, but there are some good pics of the BCDD altitude compensating bellows that they used inside there. Looks like this: Here's the thread where those pics came from: https://www.classiczcars.com/forums/topic/58748-info-on-bcdd-boost-controlled-deceleration-device/

-

Tuning at 4000’

I would first make sure that you don't have any vacuum leaks anywhere. Any leaks you have will only exacerbate lean running issues you have due to the altitude. Double dog sure. Second thing I would do is check the needle positions in the suction pistons. They should be installed with the shoulder at the correct location. If someone has messed with the needles in the past and put them back in wrong that could contribute the to uneven nature of your two carbs. Maybe one needle is installed different than the other? Beyond that... I'm surprised that 4000' altitude is enough to cause that much of an effect, but I can't argue with your results and success.

-

Weird hanging RPM issue

Yarb, My pleasure. Pochie45566, so as mentioned above... You can't just slap a BCDD blockoff plate on there and call it a day. Doesn't work. And your A/F ratio is 11.5 at 1750 RPM under no load? I'm no expert on the subject, but that's something that probably needs some attention as well.

-

Hatch Lock Button

That would be really cool if you can just swap the actuation arms and drop it in. I know there have been people looking for replacements for that hatch lock. There needs to be some sort of non-round feature between the arm and lock cylinder so the arm doesn't slip on the post. Here's how it works for the stock one:

-

Improve cold start time?

Mine does that too. I suspect your fuel check valve on the output side of your fuel pump doesn't hold pressure overnight. It holds for some shorter period of time (seconds, minutes, hours?) but not enough hours for it to have fuel pressure for that first cold start of the day. To test that theory, you can force your fuel pump to run and build pressure before you try to start the key. Couple different ways to accomplish that depending on the year, but the one failsafe version is to disconnect the small spade connector to the starter solenoid and then turn the key to "START". You should hear the fuel pump run. And I bet you'll be able to hear the difference when the pressure has reached normal. After you're convinced the pressure is up to where it should be, reconnect the starter and then start the car.

-

Small bolt extraction advice

Glad you got it solved. Too bad the bolt stub didn't come out easily, but they never do for me either.

-

No oil pressure after rebuild

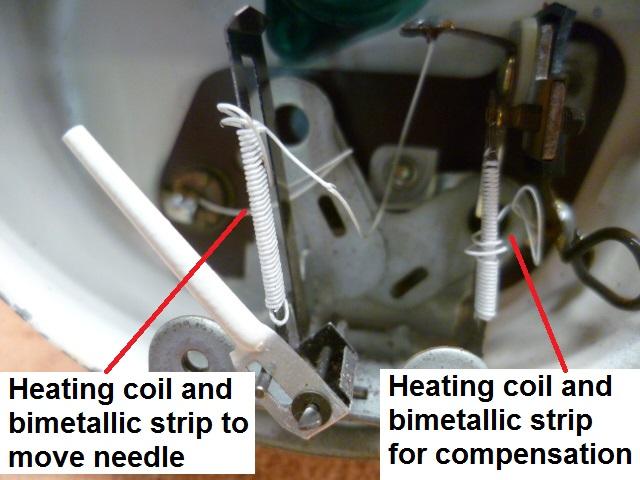

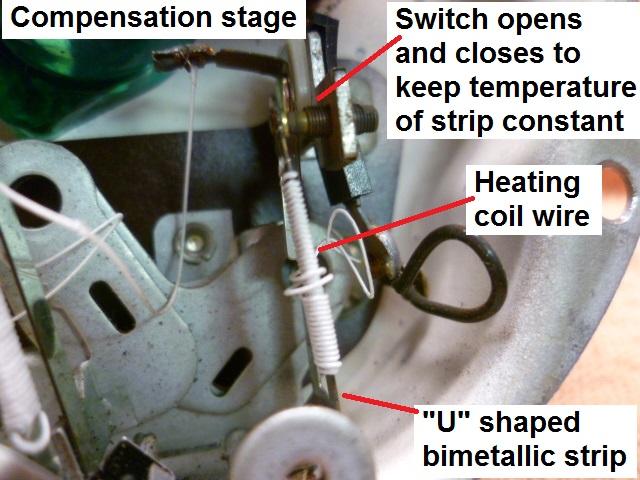

OK, I will convert this stuff to it's own thread when I get a few more minutes to make it read right. In the meantime.... I have more pics. Here's a pic of one of the gauges. You can see the two different heating coils wrapped around two different "U" shaped bimetallic strips. Interesting to note that internets research indicates that "U" shape is part of the compensation as well. The concept is that the unheated side will compensate some for changes in ambient temperature. "They say" it doesn't get rid of all of the temperature based effects, but it helps some. Between that "U" shape and the compensation stage, the gauges seem to be really stable. So this is an example of the compensated gauge with the two stages: And here's a closer-upper pic of the compensation stage showing it's parts: The switch opens and closes to keep the temperature of the compensation strip at a constant temperature (ave). If you put a Voltmeter on the sender unit, you'll see that it isn't a steady voltage, but is instead a square wave.

-

My first Z part made on my lathe

I don't consider it cheating on your first piece.. And even on piece 1000, if you aren't making some special pitch or tight fitting thread spec, it still isn't cheating. I don't remember... Is your lathe equipped to cut metric threads? Glad you're making chips!

-

No oil pressure after rebuild

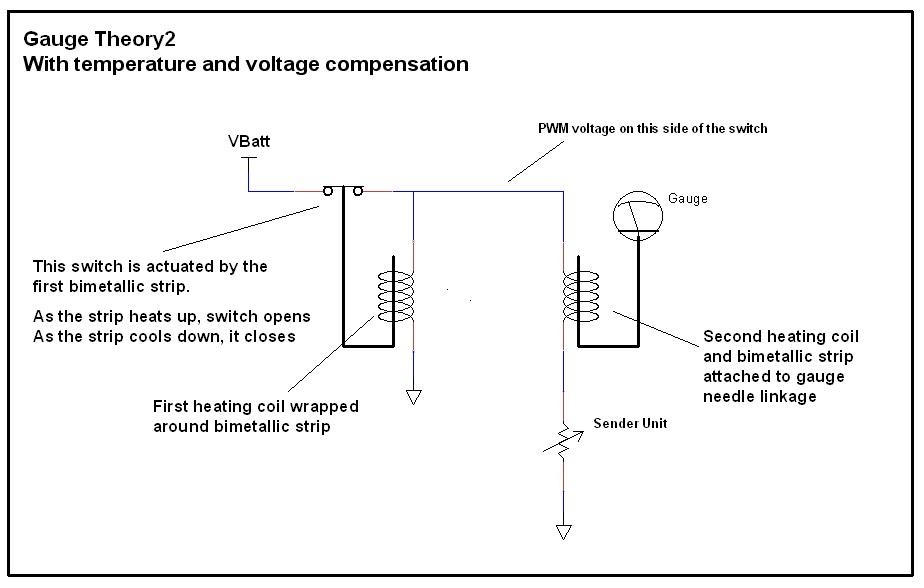

LOL. I'm pretty much out of TV shows too. I get it. There are two "stages" to the compensated gauge. One of those stages is he simple gauge we already talked about above. The other stage is the compensating or regulating stage. It's job is to compensate for changes in ambient temperature and varying system voltage. The compensation stage consists of another heating coil wrapped around another bimetallic strip. This bimetallic strip forms an electrical switch such that when the strip heats up, it breaks contact. And when it cools down, it re-establishes contact. The trick is, that it makes and breaks contact to it's own power source and the power source for the simple gauge stage. The result is that this second strip/heating coil combo will make and break the power source such that it will always achieve the same average temperature. Of course the temperature is rising and falling some, making and breaking connection, but the AVERAGE is always the same. Colder day? Power to the compensation strip will have to be on longer to reach the temp that bends the strip to the point where it breaks the switch connection. Hot day? Just the opposite. Power will be on for a shorter time. Low system voltage? Again, power will have to be connected longer in order to heat the strip to the desired temperature,. And conversely, if the voltage is higher, it'll take less time. The result is that the compensation stage creates an ON/OFF/ON/OFF pulse train whose duty cycle and frequency will change depending on the ambient temperature and system voltage. This effectively creates a voltage source that will always supply a constant amount of POWER to the gauge system under all conditions. Clear as mud? Connect that constant power source to the simple gauge from above, and you have this: If you put your key in and turn it to "ON" you should see the gauges start to rise. Don't start the car. Just pick a needle and watch carefully. You'll see the needle start to rise, but probably before it reaches it's final position, it'll pause... Then start rising again. Then pause again. This will continue until it finally reaches it's final position. And even then, if you watch carefully, you'll see the needle actually wiggles a tiny bit. This effect can most easily be seen with a needle that's moving well above minimum like a full tank of gas. That pausing and wiggling is the compensation stage opening and closing.

-

My first Z part made on my lathe

Yup! And they're often well lubed. And sometimes they even turn blue!

-

My first Z part made on my lathe

Nice. So you turned the rod OD down to accept a die for making the thread? Or did you actually cut (they call it "single point") the threads on the lathe? I'm guessing you used a die. Single pointing threads is not something you typically do on your first piece ever.

-

No oil pressure after rebuild

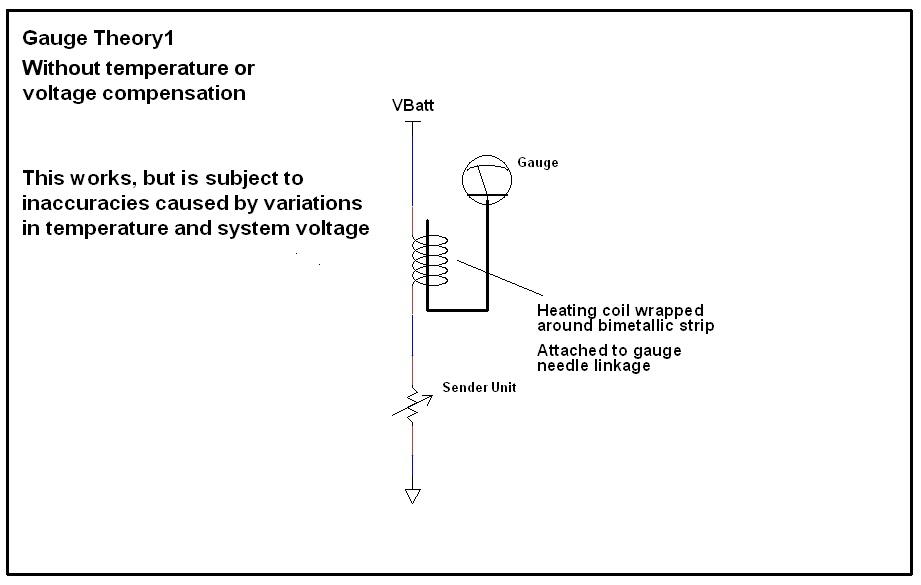

OK, I promised to describe how the gauges work... Not sure it should be here in this thread, or if I should start a new thread for this. I'll put this here for now, but if people think it should be separate let me know and I'll start a new specific thread about gauge theory. So in order to understand how the gauge system works, I think it would be a little easier to first understand how they DON'T work. I think everyone already has a good handle on this simple system, but it's an important place to start. Here's a pic of a simple (uncompensated) gauge design. Wrap a heating coil around a bimetallic strip and mechanically attach that strip to the linkage of a gauge needle. Flow current through that heating coil and to a sender unit who's resistance reflects the level of whatever you're trying to measure (temp, oil, fuel, whatever). As the resistance of the sender unit changes, the current through the heating coil changes and that changes how hot the bi-metallic strip gets. The lower the sender resistance, the higher the current. The higher the current, the hotter the bimetallic strip gets The hotter the strip, the more the needle moves. Here's a pic: This simple uncompensated gauge system does "work", but it is subject to a few real-world outside influences that can affect the accuracy: First, since the whole thing works on the temperature of the bimetallic strip, the gauge will read differently on a hot day than on a cold day. And second, since the gauges are powered by the battery system of the car, changes in that system voltage will affect the gauge readings. The gauges would read differently sitting with the engine off than they would with the engine spinning at 3000 RPM when the alternator has kicked up the voltage a bunch. The system voltage can vary from about 12V to over 14V and the gauge readings would change as the voltage varied. So the basic gauge system above sorta works, but these two real-wold effects are undesirable. If the above basic gauge system makes sense, I'll get into how they compensate for those two real-world effects.

-

My first Z part made on my lathe

LOL. Maybe he's polishing? Or waxing?