Everything posted by Captain Obvious

-

Worlds fastest production car

Dang. So who help the record before they broke it?

-

Just Another Damned Z Car Project Thread

Sure would! So by the way... Where did you find the info that said the 350Z uses the same mounting pattern as the 280Z throttle body? How credible was the source?

-

Is one carb missing a linkage?

The problem is that the needle and/or nozzle may already be worn oval. But at this point, it sounds like you just want to get the car to run reasonably well and then deal with the finer points later. If that's the case, then you can probably use the existing needles and nozzles and move forward. The problem (if there is one) will be in getting the car tuned well. Typically if the nozzle is worn oval or if there is material worn off the side of the needle, then it'll drive fine, but your idle will be rich. BTW I took a look through my round top parts and I don't have that little linkage piece you're missing. Sorry.

-

Is one carb missing a linkage?

I think the needle may have become bent because the nozzle was misaligned and binding. How bad is it? Uhhh... Yeah. He's an expert.

-

280z radio pinout?

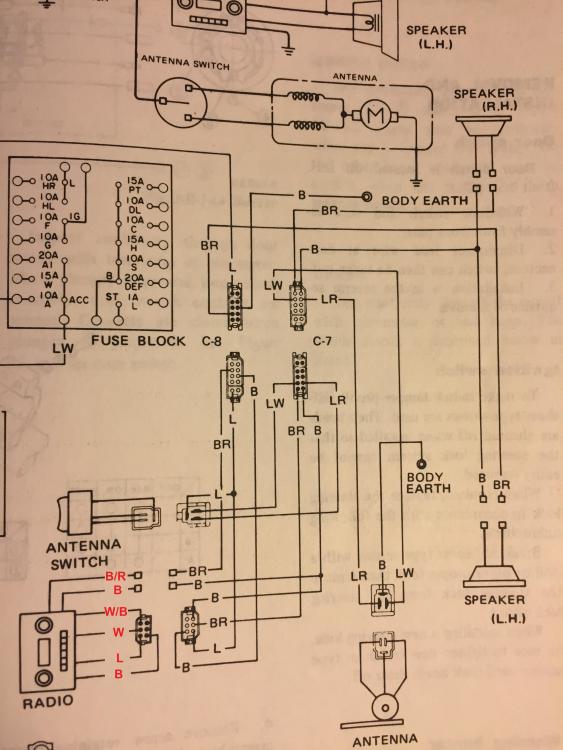

That diagram is correct. It's just more of the same issue as before where they didn't show the stub harness on the diagrams. The documentation just assumes the wires coming out of the back of the radio are hard-wired. I added the colors to your diagram to show what I'm talking about. I stand by my previous identifications of the wire colors (IN THE SUB HARNESS). They change some of the wire colors at the six position spade connector, so on the CAR SIDE of that connector the colors are different: Note that they don't show the illumination wires on this diagram because they are shown on the dash lighting page instead. But the rest of the colors all work out.

-

31K Miles Series I 240Z Up for Auction on BaT - Over $100k on First Day!

There was a comment after the auction ended by soquelz, who says "I guess when you get to this level of bidding you want no questions about authenticity." And that about sums it up for me too. If I'm going to pay a lot of money for a car who's "value" lies in it's low mileage and it's originality, I don't want it to come with piles of questions about either of those two things. It's a beautiful car. I'd love to own it. But it's priced way out of my range. And it's important to understand the REASON for such a high price. The REASON for the high price isn't simply because it's beautiful. It's because it's supposed to be a 31K mile car that is all original. If it wasn't being sold as a 31K mile car, or being held up as that beacon of originality, it would most likely not command such a price. Much of the VALUE is in the low mileage and the originality. It seems to me that when there are credible questions about the mileage and the originality, the value cannot be supported. I expect this car will be back sometime in the not too distant future. With the "period correct" carbs and plated hardware and "period correct" wheel covers and no overspray and the seats on the correct sides and, and, and, and........ And, a better, more conclusive story. And if we see it again, I hope it's presented as "Stock", but not "Original". For example... In order for it to be "ORIGINAL", they would have to find the ORIGINAL carbs. And the ORIGINAL wheel covers, etc. I hope they don't try to convince anyone that they magically and mysteriously found the original carbs and wheel covers and put them back on the car. After all the claims of complete originality of the car as it stands today, I would be skeptical of the legitimacy that story.

-

Just Another Damned Z Car Project Thread

The reason I went to ebay looking at the 350Z throttle body was to try to confirm the mounting measurements (didn't work). You said it fits the 280 plenum (60mm square), but I've never messed with one to confirm or deny the compatibility. However, if it doesn't fit, you're only out thirty bucks. So about the cold start plate, I made one out of stainless couple years ago and thankfully did not get sidetracked by nitrous.

-

C’mon! Own up ...

- Electric Pump question 240Z w/ SUs

In theory... Yes. Both fuel pumps are positive displacement types and have check valves on both the input and output sides. Because of those check valves in theory, either pump will allow draw through with the pump not on operation. So, you could pull fuel through the electric with the manual, or push fuel through the manual with the electric. In theory. Problem though is the amount of pressure drop you would get across those check valves, and would the system still be able to build the required pressure in the rail. In theory. Haha!- Is one carb missing a linkage?

LOL. Yeah, never. Just because the adjustment method involves bending pieces of the linkage, you think it's crude or something?- Is one carb missing a linkage?

Yeah, there's something wrong with that whole nozzle assembly. With that little screw out, the nozzle should slip freely in and out inside the alignment nut. The get corroded and stuck sometimes, or maybe the whole thing is so badly misaligned that it's jammed up against the needle inside the carb. That bottom assembly should not spin. There's something wrong down there. So what's the history of these carbs? It sounds like someone who really didn't know what they were doing had them in pieces and didn't do a good job of putting them back together. (Sorry if that was you.....)- 280z radio pinout?

What do the wires do? I think I can help with that: Blue is +12V power in. Hot when in ACC and ON. Blacks (two of them) are grounds The one on the 6-position connector is used as the low side power for the radio, and the bullet is used as a speaker ground. White/Black is also a speaker ground. I think it just gets connected to the black ground wires in the car harness. White is right hand speaker output. Black/Red bullet is left hand speaker output. Green/White is panel illumination high side. Goes to the headlight switch. Red/Blue is panel illumination ground side. Goes to the rheostat. Does that make sense?- Just Another Damned Z Car Project Thread

Sorry, but I don't understand your last post... I took a quick look on ebay and found that they ARE commonly available used. And cheap. You say they aren't available used, but then you say it's common to replace them with aftermarket? I'm not sure if that was a typo or what, but I saw lots of them on ebay.- COVID-19

So sorry for your loss.- Is one carb missing a linkage?

It sounds like either someone put the linkage together wrong on that carb and it's binding up, or your nozzle is just stuck frozen in place. If you take out that little screw (the really chewed up one) out of the bottom of the nozzle and completely separate the nozzle from the linkage... Can you pull the nozzle out then, or is it still stuck?- Is one carb missing a linkage?

When you get a chance, can you post a close up pic of what the front carb does when you pull up on the choke lever?- Is one carb missing a linkage?

Sorry... All that stuff I said before was wrong. The piece of linkage is what bumps the idle speed up when you pull the choke lever. The choke should work fine, but it's supposed to raise the idle too, and that won't be happening. Not sure why your other nozzle doesn't drop at all. I'll have to take a closer look at the pics...- 280z radio pinout?

And forgot... Yes, the real solution to the confusion is to actually show both ends of that little stub harness on the diagram. It's really Datsun's mistake, not yours.- Is one carb missing a linkage?

What do you mean by "functioning nozzle"? And to answer the question... As long as the return springs are still pulling both nozzles up, then yes. You can drive the car even with that linkage missing. You won't have any choke capabilities and it may be a bear to deal with until it warms up, but yes.- Just Another Damned Z Car Project Thread

Sweet. Hope it works out. And it's nice that it's from a Z!- 280z radio pinout?

I think the schematic matches the car fine. The connectors shown on the wiring diagram are a six position spade and a pair of bullets. On the car end of that sub-harness, you've got a six pin spade and a pair of bullets. Just like the diagram. The confusion comes from the fact that the connectors built into the back of the radio are not shown on the diagram at all. The diagram shows it as if the wires were hard-wired coming out of the back of the radio (just like they did on previous years). So if you plug that little sub-harness into the back of the radio and pretend it's all one piece, then the wiring diagram is spot on. The problem you're having with 6+2 or 5+3 is that the 5+3 is completely ignored on the diagram.- Is one carb missing a linkage?

And that's a good point too. I don't remember exactly where in the linkage system the return spring is for the choke.- Is one carb missing a linkage?

Just to confirm the answer you already got... Yes, you're missing a piece of linkage. The piece you're missing is part of the choke system and because of that, the choke will not function on that carb. The rest of that carb will work fine, but the choke will not. As far as getting a replacement, I have about a 0% expectation that you can buy that part from any normal commercial vendor or dealer. I think you'll need to find someone who is breaking up a carb into parts for some reason. I've got a couple spare parts for round tops around here somewhere and I'll look, but don't get your hopes up.- 260z round top conversion: a couple questions

Yes, the linkages are different. Remember back on page 1: And about the anti-backfire valve... It's got three connections: 1 - High vacuum from the balance tube side 2 - No vacuum from the air cleaner side 3 - Control line to open the valve when the intake manifold vacuum goes high enough The connection that you put the little air filter on is the no vacuum fresh air side. The other two ports connect to vacuum sources. Does that make sense?- KONI Sports for Classic Z's

Haha! It's a calling. Seriously though... Glad to help! - Electric Pump question 240Z w/ SUs

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.