Everything posted by Patcon

-

Hard Cold Start

You can unhook the choke cables at the carb and move the levers manually to check function. Also make sure they dont stick down. I have seen many do that. Once you check functionality then I would inspect the choke cable. Jacket could be broken, a cable could be snapped or it could be broken away from the console

-

Hard Cold Start

Yes they move noticeably. Maybe a ¼" or more at full choke

-

Restoring fuel/ ahmeter and other gauges in a 240z (paint and full restoration)

Not hot glue and no super glue (Cyancrylate)!

-

1970 240Z Works Rally - the road to restoration

@SteveJ @Captain Obvious

-

71 series 2 console

SEM makes alot of these products

-

Replacement Leds for Dashboard instrument lights (Speedometer, Tach, Fuel, Oil, and Clock)

Check the voltage at the horn connection

-

[2022] What Did You Do To/with Your Z Today?

That sounds fun!

-

Parts for Sale: Series 1 240z Red Dot Mirror

I was thinking it was the very early cars

-

Parts for Sale: Series 1 240z Red Dot Mirror

Which cars is that correct for?

-

Classic Zcars Site

Be very careful if you cut that up or when it's cut up!! Stumps like that come slamming back down when cut from the trunk. I have seen videos that didn't end well when somebody was in the wrong place when that stump slammed back down!

-

Gold Zinc Plating

Post up the shop name. People are always looking for a good plater

-

Gold Zinc Plating

Did you use a service or do those yourself?

-

1973 Rebuild

Looks like a good helper!

-

Maintenance crank seal service

Speedi sleeves are very thin! Sometimes it helps to heat one and cool the other to aide assembly

-

Maintenance crank seal service

The main part of the damper should have a rubber ring molded in the middle of it. Inspect it for damage. Its possible it is torn or out of balance and that's what destroyed the seal.

-

Let's show vintage racing pictures. I'll start.

Wonder how they got that up on the table? Forklift? The table looks fixed and no apparent overhead crane

-

1971 240 radiator factory finish?

I find that the gloss paints like rustoleam dull down over time to appear more satin like

-

Need ideas changing my mirrors

I probably have a set of extra frames but there would be shipping added. Terrapin probably has some too. They are stainless, so they will polish up nicely even if they're dingy to start with

-

saturday night music thread

That was so Greek to me! 🤣

-

Z's on BAT and other places collection

There's a bunch of good parts there! Good luck

-

Front blinker light clean up / new screws

Absolutely, just let me know!

-

Front blinker light clean up / new screws

How far out is the body shop?

-

Parts Wanted: Need A Good S30 Hood

I believe the young guys who are in Georgia are making reproduction hoods, hatches, as well as other panels. Their company name escapes me right now. I think a hood is about $600

-

1971 HLS30-14938 "Lily" build

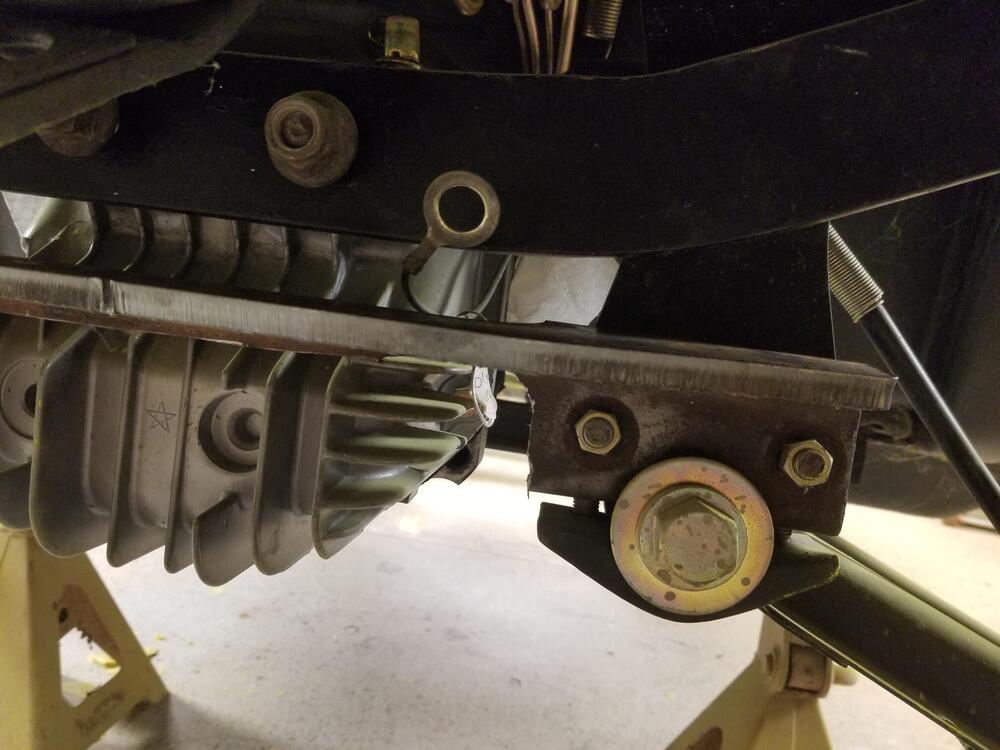

So I worked on the differential brace some more. I finally got the 3/8" steel from the machine shop a couple of weeks ago. He gave it to me free because it took so long. The sides had some beveling to them so I had to do some clean up first I checked a little more and then let Cody MIG it up for me. He was gonna TIG it but the MIG was close by so we went that route n it Cody wasn't pleased with the welds because the feed was being a little erratic, probably because the wire was dirty. I will do a little clean up on it and make it black.Should be fine for what I'm trying to do. I can post up the CAD file for the plate if anyone is interested

-

Parts Wanted: Need A Good S30 Hood

There are reproduction available too

Subscriber

Subscriber