Everything posted by Zed Head

-

Headlight Problem-No low beams-possible bad combination (dimmer) switch

The dimmer switch is actually at the base of the turn signal stalk. The parts that you're showing in your picture are the switch assembly (two switches on one board) that supplies power to the headlight circuit and the running light circuit. Notice in SteveJ's first FSM copy picture that someone wrote in "ground". RB and RW are grounded there, one or the other by the switch at the base of the turn signal stalk. I've fixed a problem like yours by spraying contact cleaner in to the base of the signal stalk and working the dimmer lever. It gets gummed up if it's not used regularly.

-

Manifold Stud Success

I was just wondering what your reason was. I have a bowed exhaust manifold that I bolted on to a head and found that it doesn't take much force at all to bend the manifold down to the mating surface. Probably a millimeter gap closed up. The surfaces may not be parallel but the tension applied by the ends of the manifold are not much different than in the middle. Not extreme, for sure. But that's the advantage of having a collection of parts. Even the defective ones are useful. My theory is that the three bolts in the middle of the exhaust manifold hold it tight to the head and that the ends of the aluminum head expand away from center farther than the steel manifold. Aluminum has a higher coefficient of thermal expansion than steel. In other words, if they start out in the same spot cold, the aluminum will grow more than the steel when hot. The hot-cold cycles bend the stud back and forth farther on the ends. That's my thinking anyway. Really, the 10.9 grade might have similar fatigue strength to a grade 7 or grade 8. It's a property that's not considered much. How do you know the Nissan studs are grade 7? I'm no bolt-stud expert, but that's an odd number. 2, 5, and 8 seem to be the common ones, American. 10.9 is a metric standard. And seems to be identical to Grade 8, property-wise. So we've probably been talking in circles.. http://www.tessco.com/yts/customerservice/techsupport/whitepapers/pdf/bolt_grade.pdf That's the beauty of the forums - you have to go learn some new stuff just to keep up. Here's an interesting book on fasteners that I browse through when things start to fade. Carroll Smith's Nuts, Bolts, Fasteners and Plumbing Handbook (Motorbooks Workshop): Carroll Smith: 9780879384067: Amazon.com: Books Might be cheaper here but it looks like his web site is screwed up. It's missing. www.CarrollSmith.com -- Purchasing

-

Refreshing The Intake

I see that you're using a "straight-shot" modified fuel rail. It's possible that you might have fuel pressure pulsing issues, or pressure degradation at the last few injectors. I think that's why Nissan fed the injectors from both sides and installed a damper in the back. I've read that the large volume of more modern rails helps counteract those problems. It will be interesting to see if you have heat soak problems with the smaller rail volume, but with headers. Hope you don't but the set of parts is interesting since nobody has that combination. p.s. I assume that you found one more injector to go with the eBay set?

-

Manifold Stud Success

It's not a tension problem. The threads would probably pull out of the head before the stud failed from tension. But it sounds like you've made up your mind. Probably not a big deal either way. Why are you following Nissan on the nuts, but not on their stud grade? Don't you want to use lock washers and threadlocking compound? Just curious about the logic path.

-

Manifold Stud Success

You can get Nissan factory-quality manifold studs from the dealer. Designed for the application. High numbers in a bolt or stud grade doesn't mean that they're better. Just that they're different. You don't need super-high yield or ultimate tensile strength, you need fatigue and heat resistance. Constant bending and heat-cycling is what breaks the studs. Better to get a stud that's been tested for the application by the factory. You can get the part numbers here, and your dealer will have them. If you get a good parts guy he can find them on his own by car model. They're common and cheap. Datsun 280Z Cylinder Head, Rocker Cover & Thermostat L28E You can get the nuts also. Notice that there are no lock washers. Datsun 280Z Manifold, Egr. L28E (From Aug.-'76)

-

E-31 head, whatch'all think?

You might measure combustion chamber volume to see what your CR will be. You might find the flat-top L28 puts you at 12:1 or something.

-

My 77 Fairlady doesn't work (HELP me pls)

Continuity is used to check if two points are connected. It does not tell you if there is power. The distributor and ignition module are involved in the injectors' opening and closing. The ECU is connected to the coil via a blue wire to the negative terminal of the coil. This wire also connects to the ignition module. The ECU opens the injectors every three sparks. The ECU also needs to have the tachometer connected to work correctly. I believe that it may be part of a pull-up resistor circuit, but that doesn't really matter. Make sure that the blue wire from the coil negative has continuity to Pin #1 of the ECU at the connector, and that it is connected to the ignition module, and that the tachometer is connected properly. The fact that the engine ran for a little while implies that you have power to the fuel pump. You can check that by removing the small wire from the starter solenoid and turning the key to Start. The engine won't turn over but the fuel pump should run.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

You're right, there is a lot of stuff out there, and it's hard to tell what's right and what's wrong. I gave up and just installed the GM HEI external coil to match the module. I think it ohms out at 0.7. I figured I couldn't go wrong with the original GM specs., used on cars like the Camaro with a V8. You know those will see some high RPM. I think that the Pertronix HEI module (there are other brands also like Accel) just has a higher current limit. With a low ohm coil, the heat dissipation is probably the key ot making it last. The new module in the old box in the cabin is certainly cooler than sitting in the engine bay or under a GM distributor cap though. Shouldn't be a problem, I'd think. Plus you can reach over and touch it while driving, and turn on the AC to keep it safe. Here are some of the other brands. Still popular. http://www.summitracing.com/search/department/ignitions-electrical/part-type/ignition-modules/distributor-type/hei

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

I don't think that the BIP373 has "dwell" control, or the current-limiting function that the HEI module does (and the 280Z and ZX modules). That is one of the things that makes the GM HEI module so useful, it won't allow the system to overheat from too much current. The BIP373 is used with ECU dwell control, I believe, and would probably burn up itself if used. If it triggered from the VR distributor. Not really sure that it would work. Are you using one? How does it control dwell? I think that you could use the BIP373 in place of the ignitor on the 280ZX ignition systems though. People use the HEI module to replace the ignitor, but the BIP3737 seems like it would do the job, for cheaper and in a smaller package. Might have problems with the engine heat though if it was installed in the same spot. Here's something interesting on the GM HEI modules - it looks like Bosch licensed the technology from GM or vice-versa for a few years and several of the outside-the-US manufacturers used the design, in different form factors. The very last one on this page looks like it is the same as the 4-pin HEI module but the pins seem more convenient. I think I've seen the same on a BMW model out there somewhere. Bosch Ignition Modules Edit - BUT, I just found it on Rockauto and it costs $204. So the more compact form comes with a cost.

-

1975 280Z EFI Problems HELP

If you read a few more threads on "running rich" you'll see it recommended often, to measure resistance of the coolant sensor circuit at the ECU. There are several connections along the way that can add resistance. What the ECU sees is what matters. Download the Electronic Fuel Injection Guide from the first link below. Get a meter, even a simple one will do. Try to find a way to measure fuel pressure. Read the Engine Fuel chapter, especially the first few page, if you want to understand how all of the parts work together. You'll waste a lot of money if you just guess and replace parts. XenonS130 - S130 Reference Amazon.com: multimeter XenonS30 Index of /FSM/280z

-

Wheel bearing life extended by periodically repacking?

I looked for maintenance information on the wheel bearings but couldn't find it. But now I see that it's also in the Owner's Manual. Since becoming an FSM advocate I almost never look in there anymore. Thanks for the tip. By 1976, maybe earlier, they were down to 25,000 mile intervals. As your link points out though, one cause of failure is contamination during repacking. It's a dilemma. Probably worthwhile to get one of those grease packing device to reduce handling if you're going to do it.

-

83' zx 5 speed in 78 280z

The non-turbo transmission does not require a new driveshaft. The turbo transmission does. The turbo transmission has a very different shifting mechanism. The non-turbo will look almost identical to what you have now. That's one way to tell, if you're already sure that it's an 83 280ZX transmission. The extra switch wires can just be left disconnected.

-

Wheel bearing life extended by periodically repacking?

The front bearings are tapered roller bearings, the rears are ball bearings. May not matter. Seems like the automakers would have installed a Zerk fitting if it needed it. I don't think that re-packing the front bearings is even a maintenance item either. I remember re-packing the front bearings on my 78 B210 a few times but in retrospect I don't think it was necessary.

-

Front brake problems

Hard to tell what's really going on then. How do you know the rears are great? They lock up but the fronts don't? That's typical of air in the front calipers. Can you pump the pedal to get it high and the brakes working? If you can pump them up then you have air in the system. If they just start braking with the pedal low and there's no change with pumping, then you have an adjustment problem. But you should not have bubbles in the reservoirs. Did you install a different master cylinder also? The stock system shouldn't have any problems bleeding the brakes.

-

Front brake problems

Many, many people have problems bleeding the brakes after installing calipers on the rear. Many. Quite often they have to remove the caliper, install a block of wood between the pistons and hold the caliper so that the bleed screw is at the top. There are people on this forum who have spent weeks. maybe even months, trying to get their rear caliper conversions bled.

-

Front brake problems

So what you mean is that you can't get a firm high pedal. The pedal drops too low before you get any braking action, or you have to pump the pedal to get any brakes. ??? One pretty common error that people make is to put the calipers on the wrong sides. They will fit either way. The bleed screw needs to be at the top of the caliper, not the bottom.

-

Front brake problems

There's a spring that brings the pedal up. Can you pull the pedal up by hand?

-

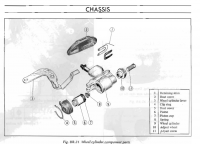

Need help figuring out how to remove rear brake piston cup please

Datsun 240Z/260Z/280Z Rear Brake (Drum Brake) (To Jul.-'76) The Service Manual is always useful. Better drawing too. Looking at the pictures and having worked on similar things, I think that the seal you're trying to replace just slips off over what you're calling the metal disc. The "metal disc" is actually the top of the piston (as CO suggests above). It's all one piece. Slip a thin screwdriver or pick under the rubber and it should peel off. It's doughnut shaped.

-

Gremlins in my Fairlady's Ignition System

Not quite. You probably have other problems besides the ignition module. Meter, meter, meter, meter. You have the meter and you'll have to crawl up by the fuse box anyway. You can actually take the voltage measurements at the ignition module before you disconnect it. Which you will have to do anyway if you install an HEI module. If you disconnect the blue wire at the ignition module and still measure 8 volts when the battery has 12+, then your problem is elsewhere. Turn key On, measure voltage on blue wire at module to ground, turn key Off, do same.

-

Gremlins in my Fairlady's Ignition System

For future reference, that is your TPS (throttle position switch). There is one other very simple possible fix, maybe short-term, for your ignition module. In your case (no offense) it might be a quick easy way to test. Your 1977 car probably has two ignition circuits in the module, like my 76 did. It may be that one is damaged, but the other is okay. You could disconnect one,leaving the other in control. But you really need to confirm that the problem is in the module first. You could easily damage the HEI module when installing it (they're sensitive to wiring) and you wouldn't know any more afterward than you do know. The meter will tell you what you really need to know before you make any changes.

-

Gremlins in my Fairlady's Ignition System

We're on a do-loop for picture taking. Actually, the GM HEI module can be made to work with the ZX distributor. Same red and green wires, just contained inside the distributor. If we pull enough of these teeth, this engine will eventually run.

-

Gremlins in my Fairlady's Ignition System

8 volts implies that you have a short circuit, maybe in the ignition module. I assume that you're measuring from one of the terminals on the ballast or at the coil, to ground. 8 volts would happen if current was flowing. Your coil would probably get hot also. Disconnect the blue wire that comes from the harness (going to the ignition module, on the ned in your picture with the brass nut showing) and connects to the ballast and see if the 8 turns to 12. If it does, then disconnect the blue wire at the ignition module (inside the cabin) and reconnect the blue wire at the ballast and check again. If you get 12 again, then you can be fairly certain that your ignition module is shorting out. I think that the mystery blue wire connects to the condenser/capacitor. It's a small silver can-shaped thing that usually bolts to the coil bracket, I think. It's not necessary and having it disconnected takes it out of the picture as a problem source.

-

Car statred running bad suddenly

Could be something simple like a plastic bag in the fuel tank. Floats around until it hits the outlet to the pump, gets sucked over by the flow, kills the engine, then floats away when the pump turns off. It would be good to know fuel pressure when the problem happens. Get a gauge, and use zip ties to hold it where you can see it while driving with the hood partially open. If you have full fuel pressure when the engine dies you can stop looking at fuel supply and start looking at other areas. Edit - I overlooked the part about smelling gas. Knowing fuel pressure is still important, but the sudden dying, then restarting, with a gassy smell is what my 1978 ECU did when it died. I had a 78 parts car in the garage that I could start and let idle until it was warmed up with no problems. One day I put the 78 ECU in my 76 driver just to verify that it was a good spare, drove about one mile and it coughed once, then died. It restarted, went about 1/4 mile and died again. It did the same about two more times until I decided to run home and get the other ECU. Reinstalled it and drove home with no problems. Just a possibility. It's not common but it does happen. Eventually, just to see if I could, I replaced the two main transistors in the ECU and it worked correctly. I think that the transistors can go bad just like they do in the ignition modules, causing extra activity on the circuit. Too many sparks for ignition, too many injections for the ECU.

-

Will this be OK?

Purty. Is that garage art? I see you got the obligatory toe shots in also, stealthy shadow mode. Nice. If you jack the right rear of the car up maybe you can swap the elbow for the plug without losing any coolant. Worth a shot.

-

Brake line clip on strut

That looks like a good way to do it. The picture shows it with the clip out. How is it with the clip in? If the clip is tight, it should be fine. It can't go up or down because the fitting is slotted in to the bracket and it can't force the clip out because the gap is too small for the fitting. The line can only come out if the clip comes out first and the fitting moves up.