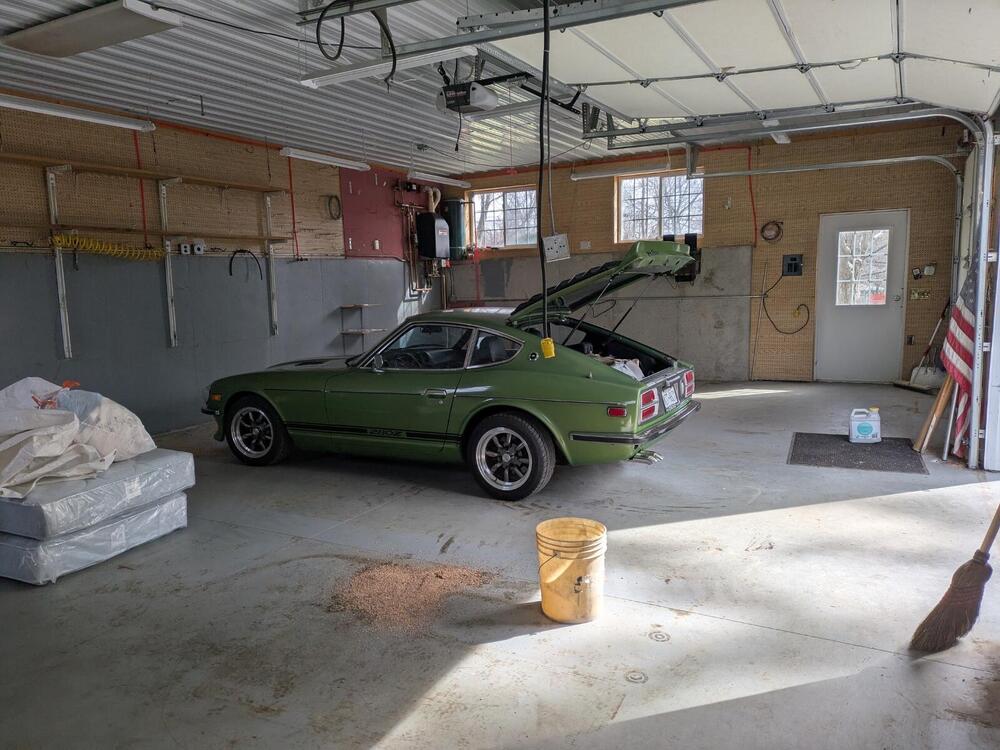

Finally got it all back together! Had a few issues, nothing serious. My horn and dome light aren't working, I'll try to fix those later. I did have to run a new separate wire for the tach out to the coil, so tach works fine now.

And I broke my glove box door! 😡 While installing I latched it close without taking the time to adjust the latch correctly. Of course it got stuck and I had to resort to prying it open with some plastic pry tools. As soon as it popped open it promptly broke those plastic flex hinges. I figure I could just get another off eBay, or order a 3rd party metal replacement inner door, until I saw the prices.

My first thought was to use some small steel hinges to fix, but that seemed a bit heavy-handed. So, I ordered some plastic flex hinges off of Amazon. Original is also a flexible plastic hinge, which I'm surprised lasted ~50 years. I cut new hinges to approximate length of the original hinge.

Used a utility blade to flatten out the area where the door side hinge adhesive will stick, 3 places.

I pried open the channel so the hinges would fit inside, but not too far that it won't act like a vice when removing tape from adhesive and installed. This will make the channel about 1/16" thicker than original, and I did use slightly longer screws when installing on the dash.

I removed the tape over the hinge adhesive and assembled. I did pry open the channel so I could slide hinge into position. And I marked the horizontal alignment to match old position, then glued door in place.

Here's the back side. The old broken side of the hinge, which use to fit inside the channel, is not used, on the shelf.

Side view of hinge.

Installed. Too bad those hinges don't come in black.

One other thing I did was epoxy a washer on the back side of my new map light bezel, so hopefully it gives the screw something to push against and won't crack again.

Done, except for the dome light and horn. I'm very happy with the way new da$h fit, although it was quite a project to install it. Car has collected a lot of dust while sitting, time to go blow the dust off it!