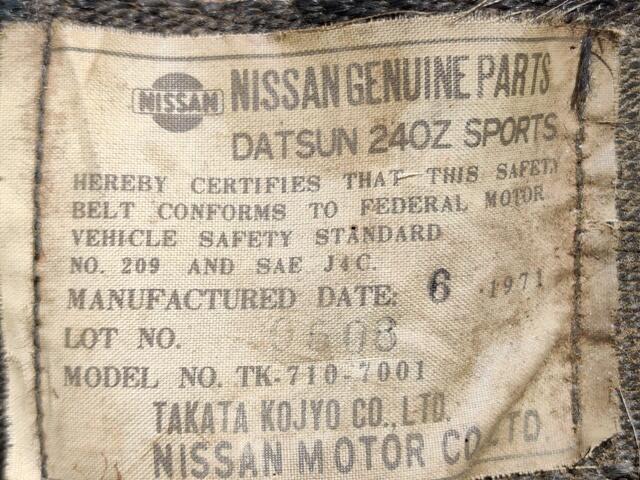

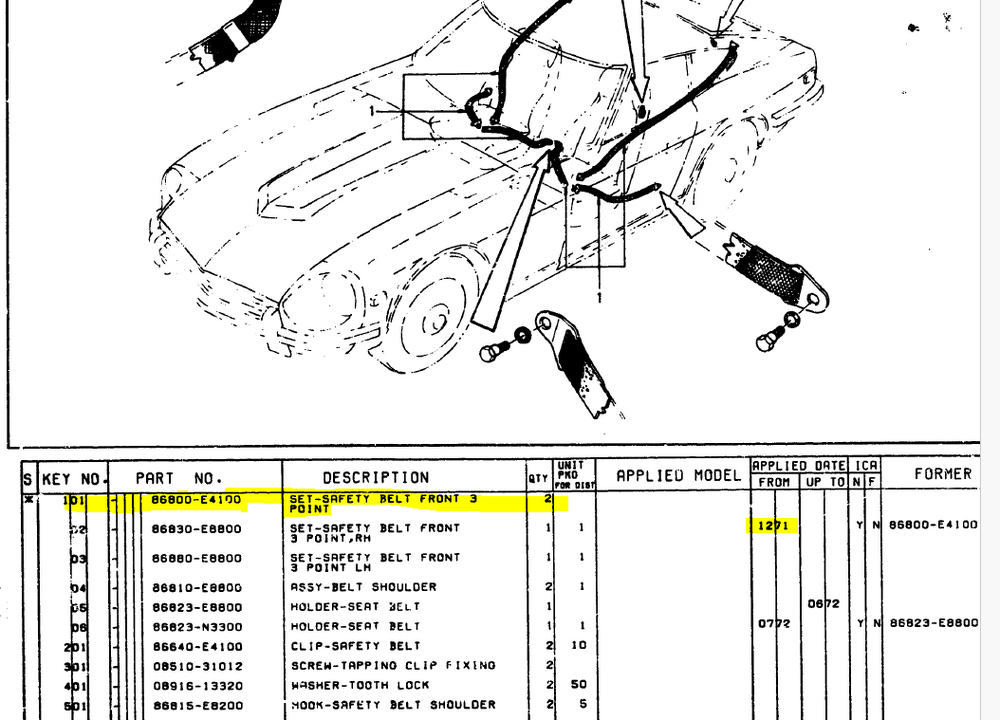

My Nissan parts book shows that the same seat belt assemblies were used until 12/71.

Do your seat belts have a push button to release, or a lift latch similar to that used on aircraft. The early style is the lift latch type, which I believe your car should have. If I'm mistaken, hopefully others will chime in.

The clip in your hand, in your last picture, is for the lower end of the shoulder belt where it would attach to the lap belt as in this picture from my 1970 with the early style.

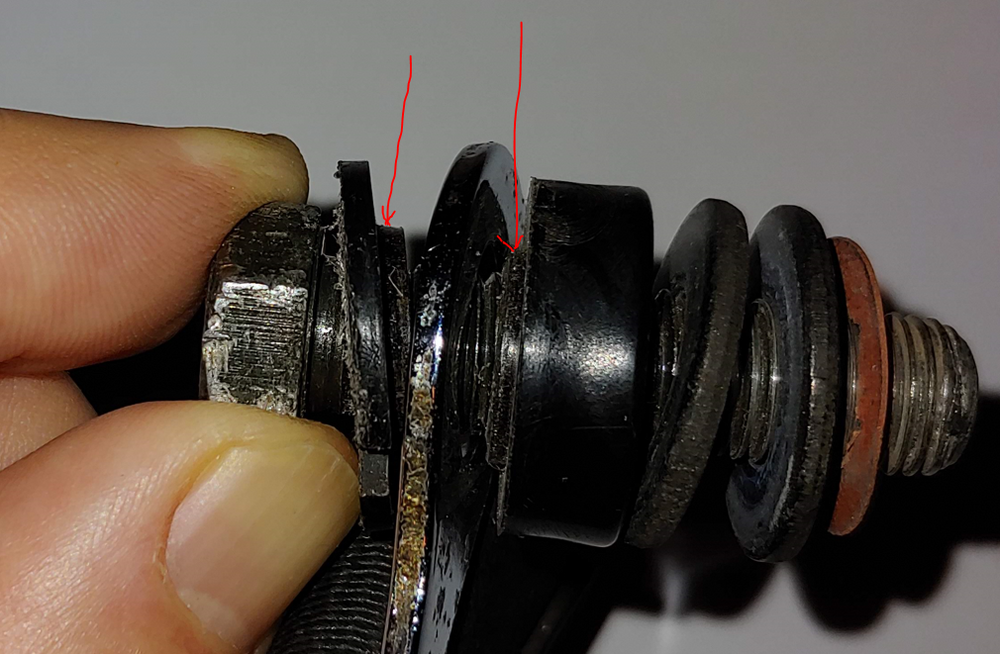

Here are a few pictures from my 7/70 showing how the upper end of the shoulder belt was fastened. It did swivel, but with some effort, not freely, when the bolt is tight. I hope they might help.

Notice the step on two of the plastic washers, they are what allows the swivel to happen,

Subscriber

Subscriber 2Points2,228Posts

2Points2,228Posts Subscriber

Subscriber 2Points11,142Posts

2Points11,142Posts