I didn't have much time this weekend to work on the car. Main accomplishment this weekend was getting a suitable shift boot installed. I didn't take pictures, but basically I used a stock 240SX rubber shift boot and a metal ring to seal up the hole on the top of the transmission tunnel. The 240sx transmission fits nicely in the car, and places the shifter in the stock location (unlike the 280ZX transmission). To seal the tunnel opening, which I left stock (uncut), all I had to do was bend the metal sealing ring at the edges. The diameter of the boot and the associated ring is wider than the top surface of the tunnel. So, by bending the metal ring on the sides, it folds those downwards. It took a while to get it shaped properly. To install it, I drilled holes in the top of the tunnel sheet metal and installed rivnuts. This is one of the very few (and insignificant)sheet metal modifications on the whole car. However, removing the 240sx transmission and installing the stock boot, etc. can easily be done.

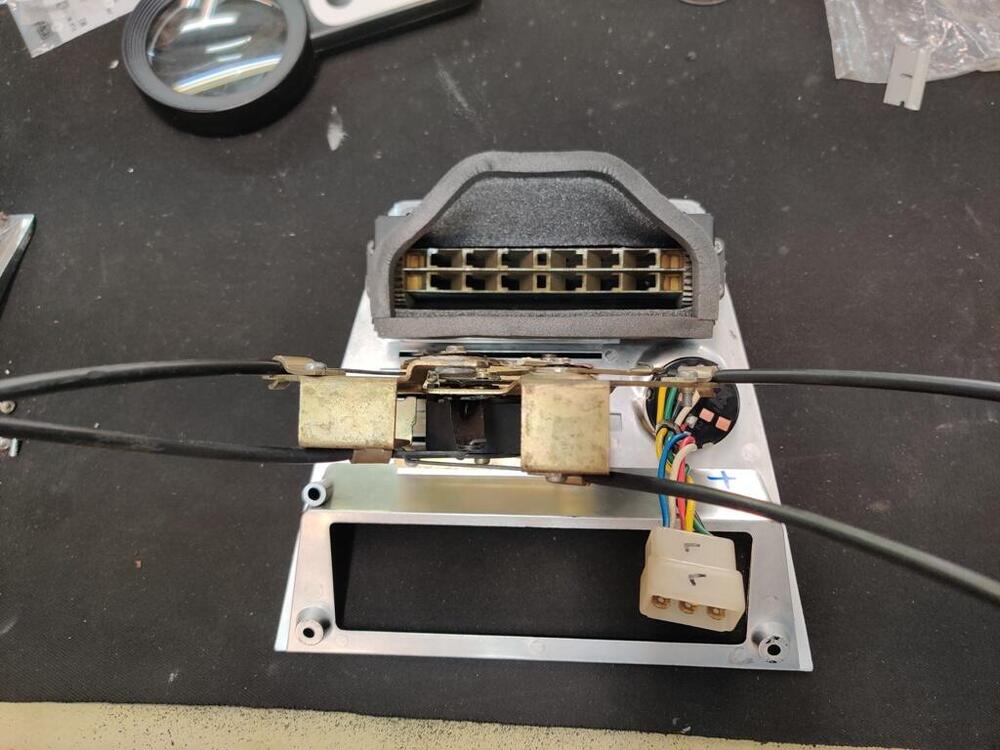

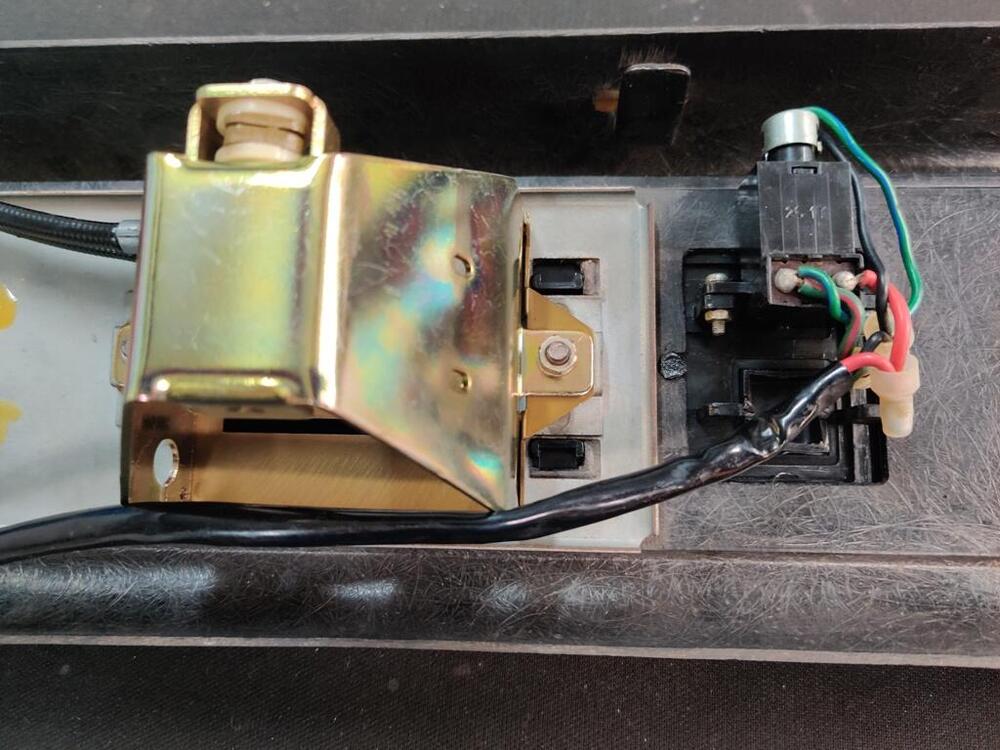

In addition to finishing the center console, I am in including some pictures from earlier work restoring the map light and cigarette lighter. Interestingly, the little picture of the cigarette is not painted on. If you remove the little disk from the lighter, you will see it is two pieces of plastic, one white and one black. The cigarette with smoke rising off of it is actually part of the white backing piece. So, you can sand and polish the disk without worry of "erasing" the cigarette. I also polished the map light lens. The map light as disassembled, electrical parts polished, and then reassembled.

I took apart the center dash controller, cleaned and lubricated everything, then reassembled it. For all of the cables, I removed the metal wire from the plastic sleeves and straightened any kinks, polished the wire, and reassembled them. Center panel is an aftermarket reproduction part. I found that I had to file the opening for the fan switch a bit (off of center) from its original location to get the fan switch to align with the off, low, med, and high settings.

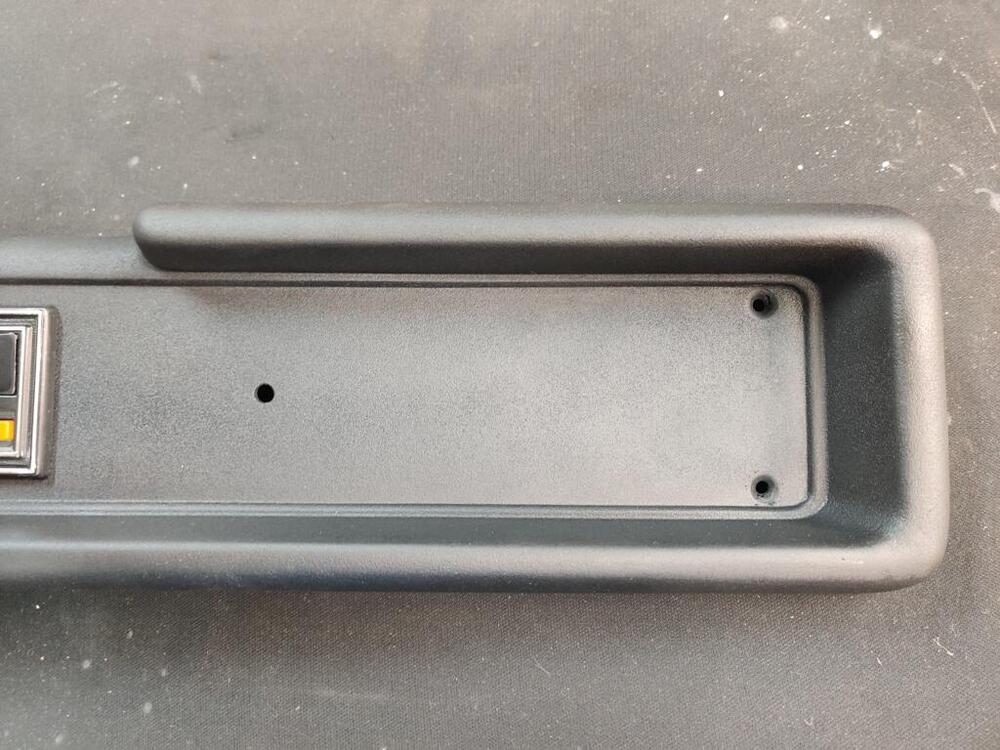

Stripped old foam and paint off of this piece, cut new foam and glued that in place.

There is a metal strip that gets glued to the center console on the front inside surfaces. The old glue was still present and helped me "locate" the strip in the correct location after I glass bead blasted and painted it. The glue I used was a 2 part epoxy (which incidentally has a similar appearance to the glued used originally).

For the starter cables, I replicated what I did for the center panel cables. I removed the hard wires from the cable housings, carefully straightening any kinks, and then used metal polish to clean the wires. For the cable housings, I sprayed WD40 inside of them and then blew them clear with compressed air. I then rubbed lithium grease on the hard wires and reinserted them in the cable housings.

The console fit nicely when I finally installed it today. I didn't get any pictures showing the installation of the reproduction shift boot, but that fit well. It looks stock, which is nice. The center console was one of the big projects left to do and it feels good to have that done.

Subscriber

Subscriber 2Points428Posts

2Points428Posts Subscriber

Subscriber 2Points1,282Posts

2Points1,282Posts