I recently visited with @inline6 to see if I could help him with an issue with his wiper motor. Though we thought we fixed it, my meter readings said we still had a problem. It turned out to be a self-inflicted issue that @Captain Obvious helped me to understand.

Thanks to @inline6 finding an old thread (linked below) and @Captain Obvious getting me to focus on the diagram in the FSM, I was able to develop a better understanding of how the wiper circuit works. I hope I can convey it clearly in this thread. Anyway, here is the thread @inline6 found:

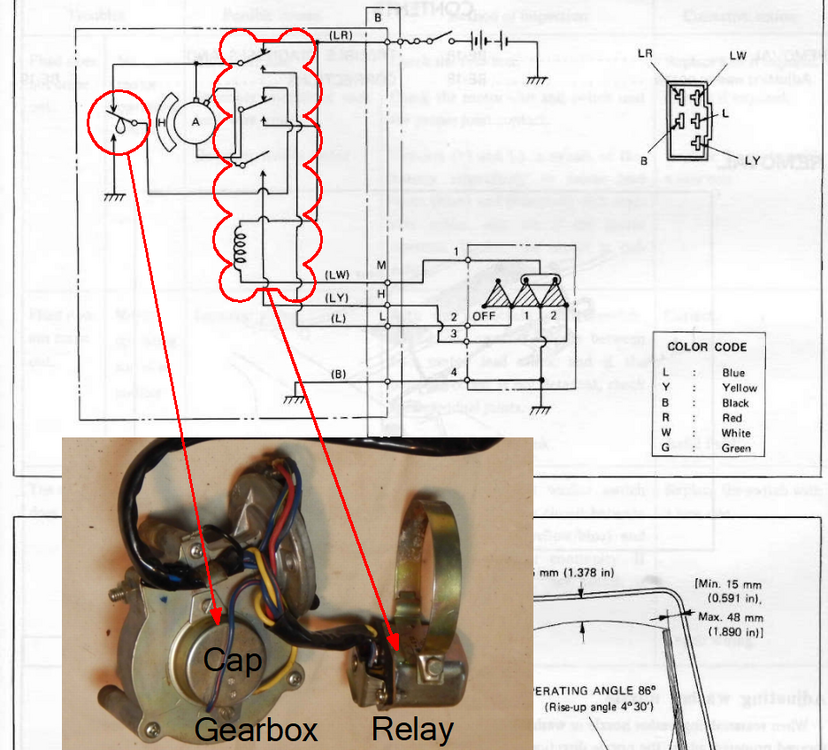

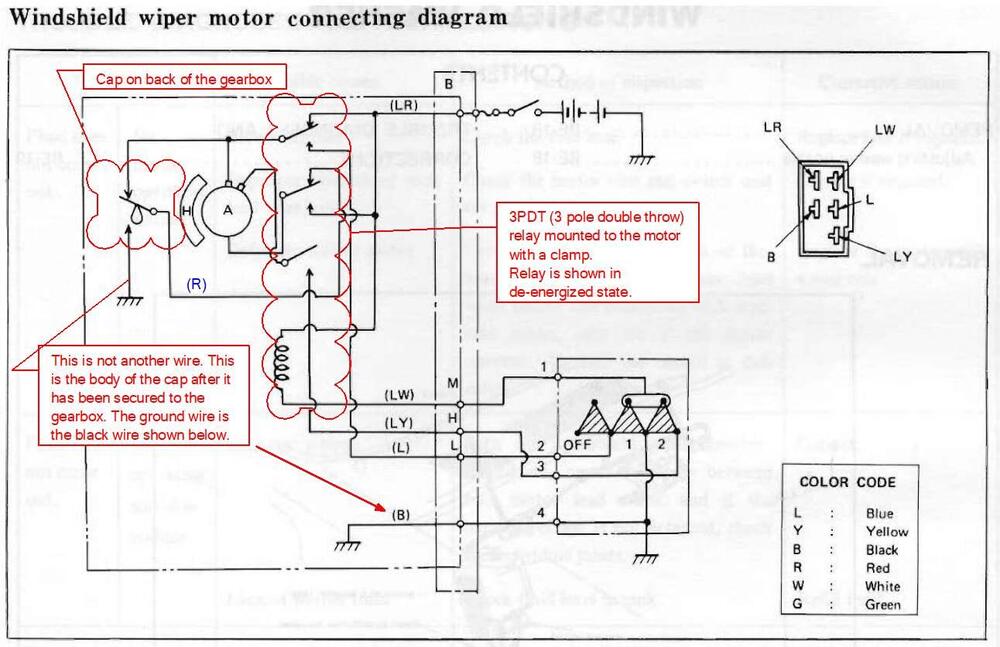

Page BE-17 of the 72 FSM shows the wiper circuit, but it is confusing because it is a challenge to relate the diagram to the physical layout of the components. It also shows how the circuit is when the wipers are parked.

The motor is not in the first photo, but the relay clamps to the motor, and the gearbox attaches to the motor.

The relay is a 3-pole, double throw (3PDT) relay. In it's de-energized state, the contacts connect the motor to run in reverse for parking.

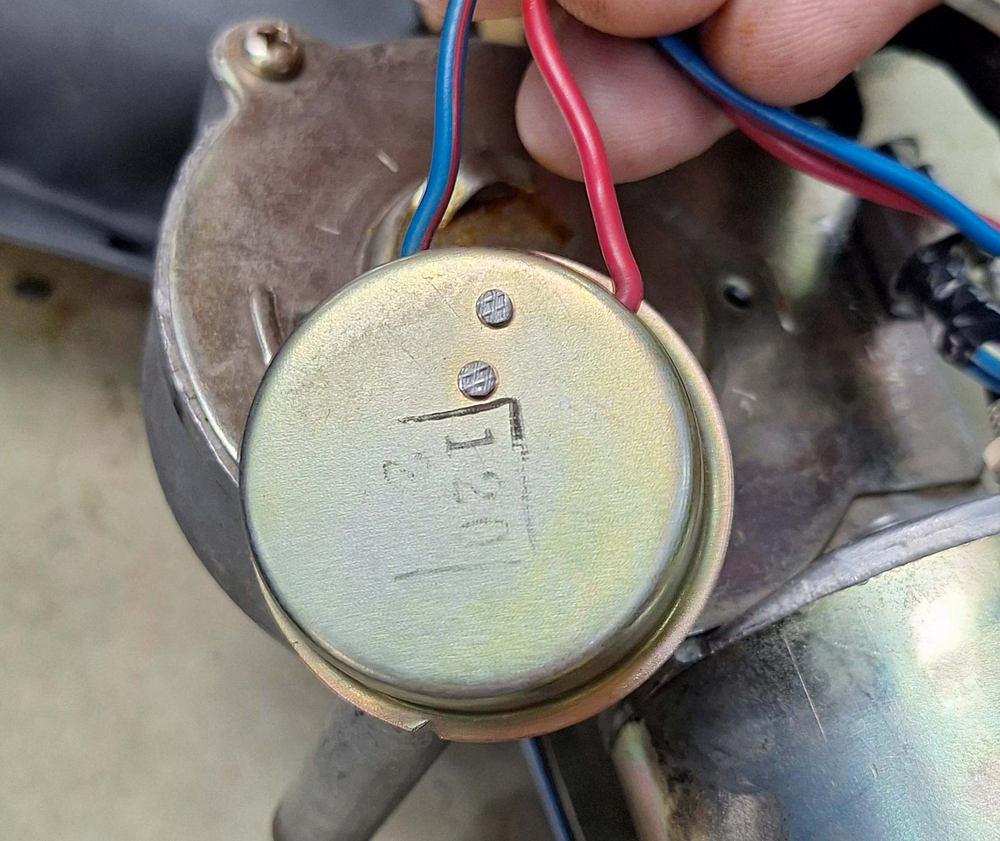

The cap on the gearbox has a blue/red wire and red wire. The picture above is for a 73, but it was the clearest picture I could find. If you look carefully, you can see two rivets on the cap. On the other side of the cap, there is a set of contacts. These contacts allow the gearbox to break contact between the armature and ground when the wipers are parking.

The gearbox has a wheel on the back with a raised area to push on the contacts.

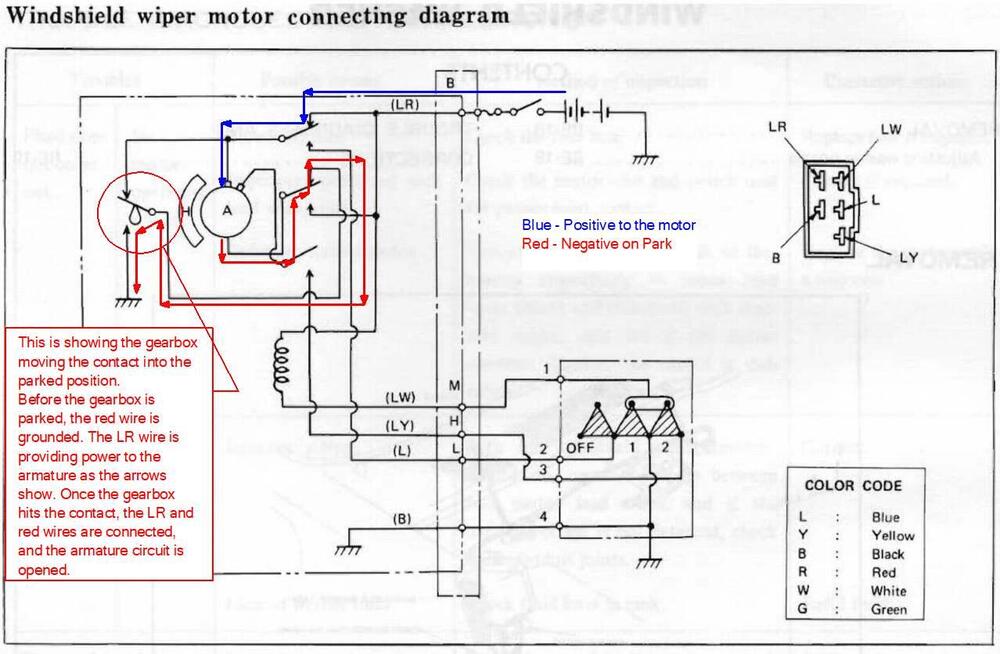

When the switch is turned on, the relay is energized. The blue arrows in the diagram below show going from the positive of the battery to the motor. The green lines show the contacts closed. The return path from the motor to ground depends upon the position of the wiper switch. If the switch is in low, follow the brown arrows. If the switch is in high, follow the red arrows.

When you turn the switch off, the relay is de-energized. The contacts in the relay go back to the normally closed position. This reverses the power flow through the wiper motor. The motor keeps going until the wheel in the gearbox comes into contact with the contacts in the cap. At that point, the current return path for the motor armature is opened up. (Actually, both sides of the motor see the positive wire.

This isn't an easy circuit to understand, especially if you've never taken a wiper motor apart.

Subscriber

Subscriber 3Points1,301Posts

3Points1,301Posts