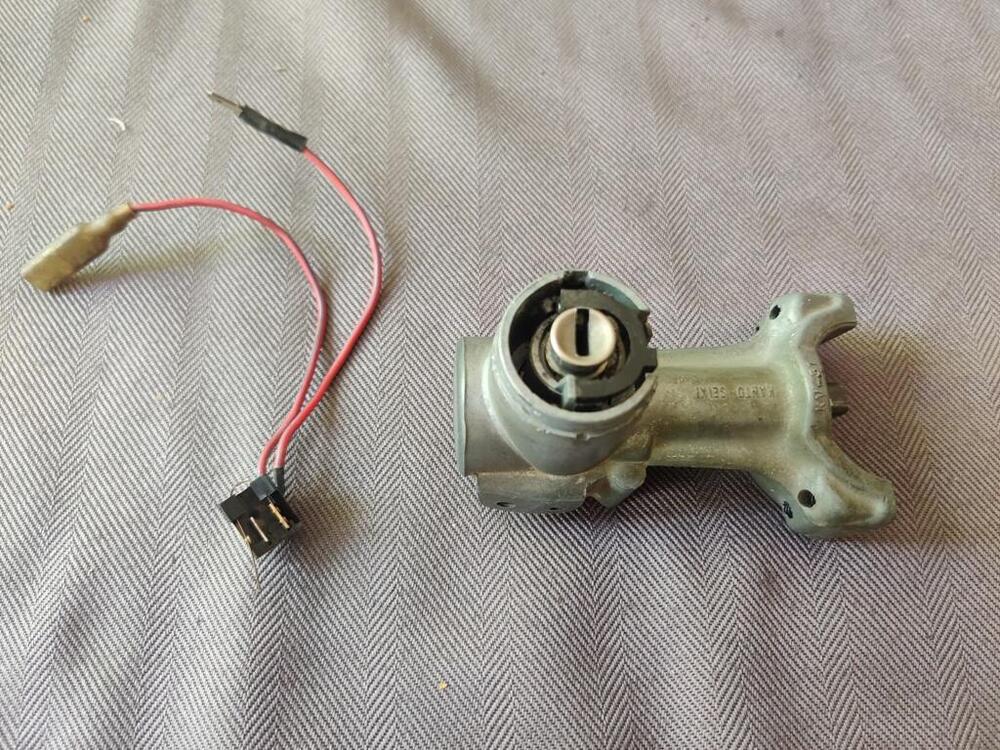

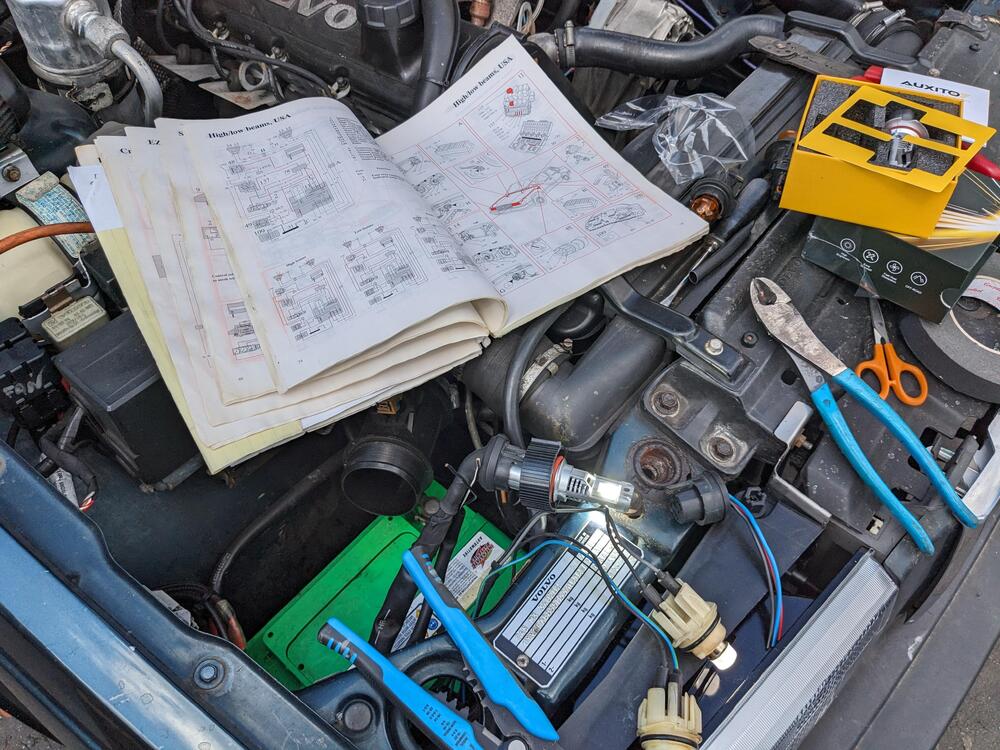

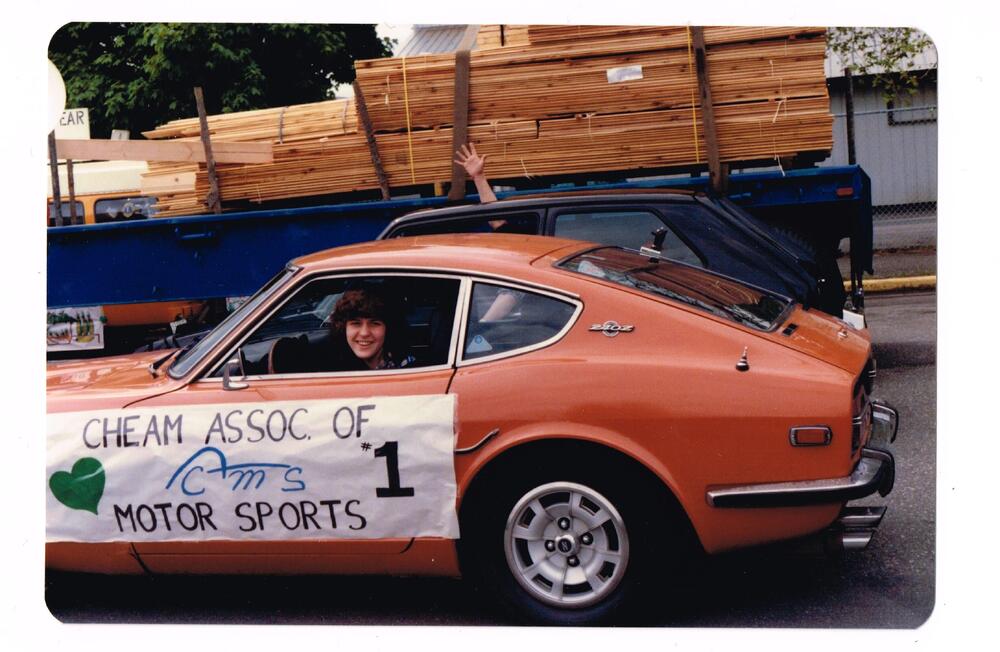

This weekend, I disassembled the new Kanto Seiki ignition switch I got from Japan and changed out the wafers to work with the new, original keys that came with a new old stock hatch lock I bought off of eBay a while back.

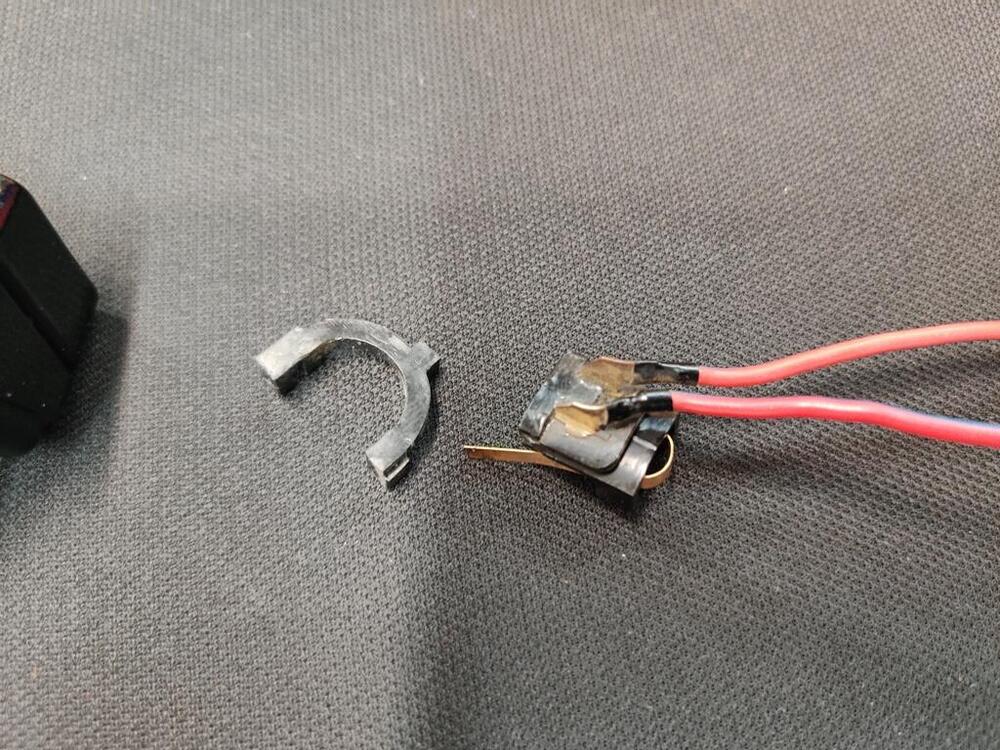

I found this link to Ratsun forums to be helpful with getting the key tumber out of the switch assembly. In order to get to the wafers, you have to remove the tumbler assembly which requires removing a small steel pin. I drilled as small hole in a spot that allowed me access to the backside of the pin. I was able to push it out and then pull out the tumbler assembly. After I got it out, I swapped a few wafers so I could use the keys with the black paint on them.

The new ignition switch did not have these electrical wires. However, these were easily moved over to the new switch.

All done:

That was the light work for the weekend. Then I switched over to the hatch glass again. I have been dreading getting back to this, because I knew it would require many hours, and I was a afraid that even after investing many more, I would not achieve a satisfactory result. Last time, while I achieving success with removing the deep scratches that were in the glass, I was not having much success getting the glass shiny again.

I picked back up with experimenting with the polishing compound that came with the kit. After repeatedly going over a relatively small area, I was unhappy to see I had made next to no progress. I just seemed to be going through polish with no real improvement. The manual said that if the polish wasn't working, I may need to got back to the previous grits. So, I decided to get my magnifying glass and have a closer look. Under magnification, I could see that the polish wasn't doing much even in the area I had concentrated on. I also saw, however, that there were some scratches left over from the first grit. Clearly, I would have to revisit use of some of the prior grits and rework.

So, I used the magnifying glass and the green grit (second stage) until I had addressed everything I saw. Then I switched to the blue grit. I went over everywhere that I had used the green. I also went beyond where I had sanded with the green by a couple of inches. For the most part, the sanding scratches looked like )))))))))))). So, when using the blue grit, I went 90 degrees to that, so I could see when all the scratches from the green grit were gone. I used the magnifying glass to check progress.

When I was done with the blue grit, I switched over to an Eastwood glass polishing kit I bought a long time ago to polish some wiper marks out of my BMW windshield. From memory, I recalled that the Eastwood kit was able to remove the wiper marks, but also polished that glass back to normal finish. So, rather than using the polish that came with the new kit, I decided to use the Eastwood kit instead.

The Eastwood kit contains a powder. To that, you add water. Within a few minutes of polishing with this, I was able to see much better progress with the polishing stage. So, I kept going this route. I also utilized a laser thermometer to check heat, as polishing can heat the glass quite a bit.

Polishing glass... is not easy. When I quit yesterday, I had worked on the hatch glass for 6 hours straight with just one 10 min break. And it wasn't done, but I no longer feared that I wouldn't be able to use the hatch glass.

Today, I picked up where I left off with more polishing. After another two hours, I called it good enough. I put the factory original weather strip on the glass and proceeded to install it on the car. While that didn't go well, and I became highly irritated, I did eventually get it in.

So, I have something like 14 hours of work in polishing the hatch glass. I have learned a ton about how to remove scratches. The kit I bought from Europe will remove deep scratches. But, it takes a lot of time and very careful work with the sander and the grits to get the glass back to a point where you can polish it. I think the polish that came with the kit is worthless. Perhaps it is ok on non-tempered glass. Instead, I recommend using the Eastwood product for the final polishing.

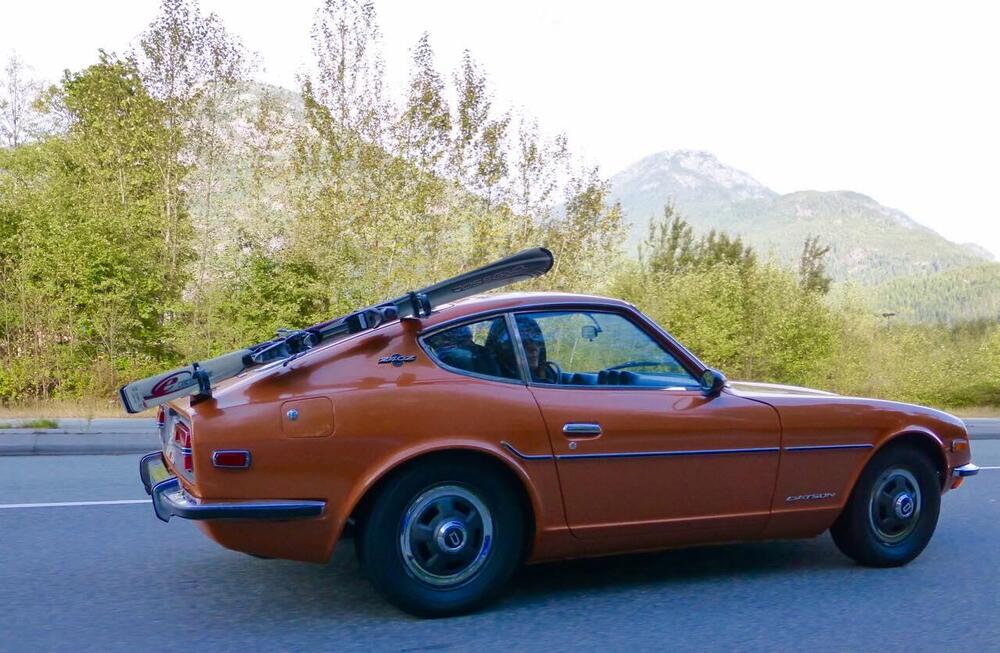

Is it perfect? No. But, I got rid of a bunch of deep scratches and I learned a lot. If I had to do it again, I think I could get the time down to around 9 hours which is still crazy, but for what it is worth, I was able to save the original hatch glass:

Subscriber

Subscriber 7Points1,282Posts

7Points1,282Posts Subscriber

Subscriber 3Points3,770Posts

3Points3,770Posts