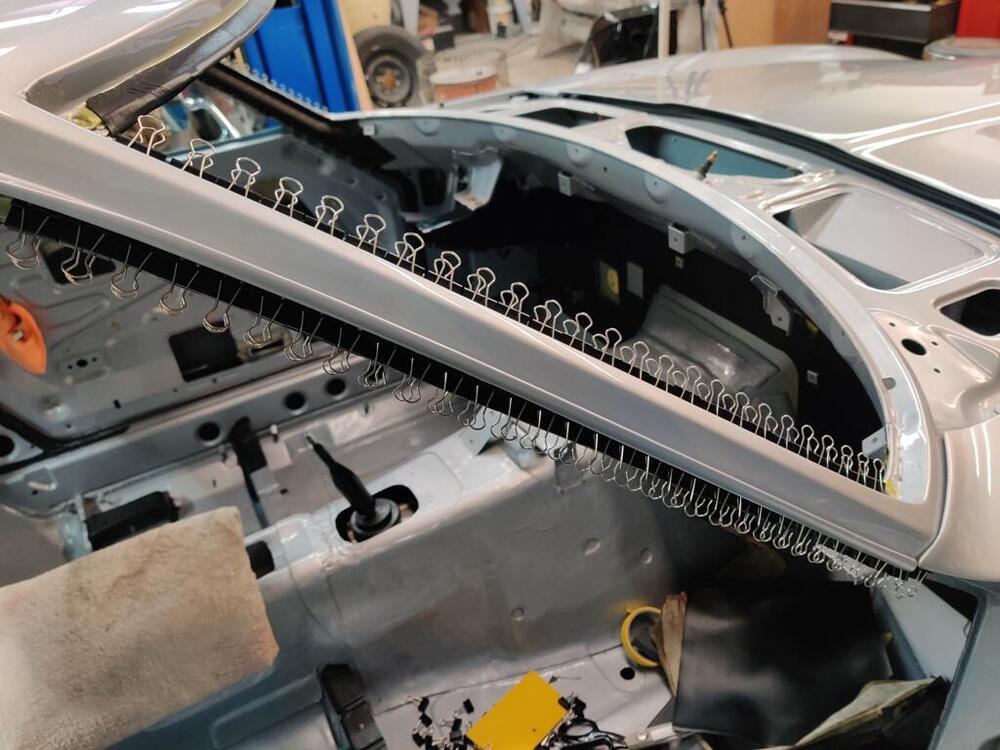

Yesterday, I completed the very difficult task of installing the vinyl A-pillar/side trims. I took my time. I found it helpful to examine the old ones very carefully while trying to get the new ones installed properly. I discovered that the quarter windows have to be out to install these properly. So, I had to take those back out temporarily. Like many things, it is a whole lot easier when you have done one. The second one was much easier and took much less time to install. The only part that didn't turn out perfect is where the side welting butts up against the header. I left a bit more vinyl material there than I should have. If I could do them again, I could get them perfect. But, it isn't worth spending all the time and effort to rip out these, cut new ones and do another install. I found the clips to be more useful with these because I wanted the vinyl to stick to the inside of the weld flange too. It sticks perfectly to the outside of the weld flange without the assistance of the clips. But on the inside, the vinyl is at an angle pulling away from the flange. The clips help it seat there.

I had today off from work, so in addition to the usual weekend hours, I was able to spend another 6.5 hours on the car. 🙂

The rear hatch glass has been sitting in a corner waiting... for the scratch remover kit I ordered to show up, and for me to devote time to removing the scratches.

The kit has arrived:

I found out about it on Youtube. I was intrigued when I saw a video that showed removal of a deep scratch. I had used Eastwood's kit, and found that it was barely adequate to remove some light wiper marks from my BWM M3 windshield. That is not a fault of the product, but I did not realize until I saw this video that there was a product that could remove deep scratches. But, I did not choose to work on that today.

Like the rear hatch glass, I cleaned my windshield and installed the NOS rubber weather strip on it. I bought the windshield a few years ago when I was finding it hard to source a windshield without the blue "stripe" of tint across the top. It was made in China, but appears to be a decent quality one.

I am going to wait for a warm day and put the windshield out in the sun. I want the weather strip to heat up and relax in the sun before I attempt the install. I will do the same for the hatch glass.

I had not yet shared pictures of the new firewall insulation installed. When I applied the vinyl to the foam for the new headliner, and while the contact adhesive was in the spray gun, I installed them.

I think they turned out to be very nice.

I was held up on finishing the installation of the windshield wiper motor and mechanism because I was searching for a suitable replacement for the plastic "push clips" that hold the wiper bag end together. I found these at McMaster-Carr and they turned out to work nicely. After snapping them together, I just use small clippers to clip the extra portion of the post off.

Additionally, I came across a forum thread in which @Captain Obvious described the proper function of the wiper arms. I had no idea that the round spring that always breaks was responsible for changing the off/resting position. I saw where some had bent the end of the existing, broken spring, so that it has a new "tang" to fit into the slot. I modified my spring today (third pic). It works perfectly - I can rotate it with ease in one direction and when I rotate in the reverse direction, I can feel the spring acting like a "one-way clutch". It grabs the eccentric piece you see and rotates it, which because of the offset, changes the length of the wiper arm assembly just a touch. This is what alters the "parked" position of the wipers to something just a bit lower than that of in operation mode. Cool!

I believe this is the correct way to assemble the linkage to the motor, but I will leave the wiper off when I turn on the wipers to test them. Thanks for the tip @emccallum!

Next, I moved over to gluing some more parts. Wiping the tool door cushions with lacquer thinner cleaned them up nicely. Then, I used a small brush and the same contact adhesive to install them. In this case, I didn't put adhesive inside the groove of the rubber cushions, as that would have been difficult and would have made a mess. Because I only put adhesive on the metal, I used the file clips to hold the cushions in place until the glue could set.

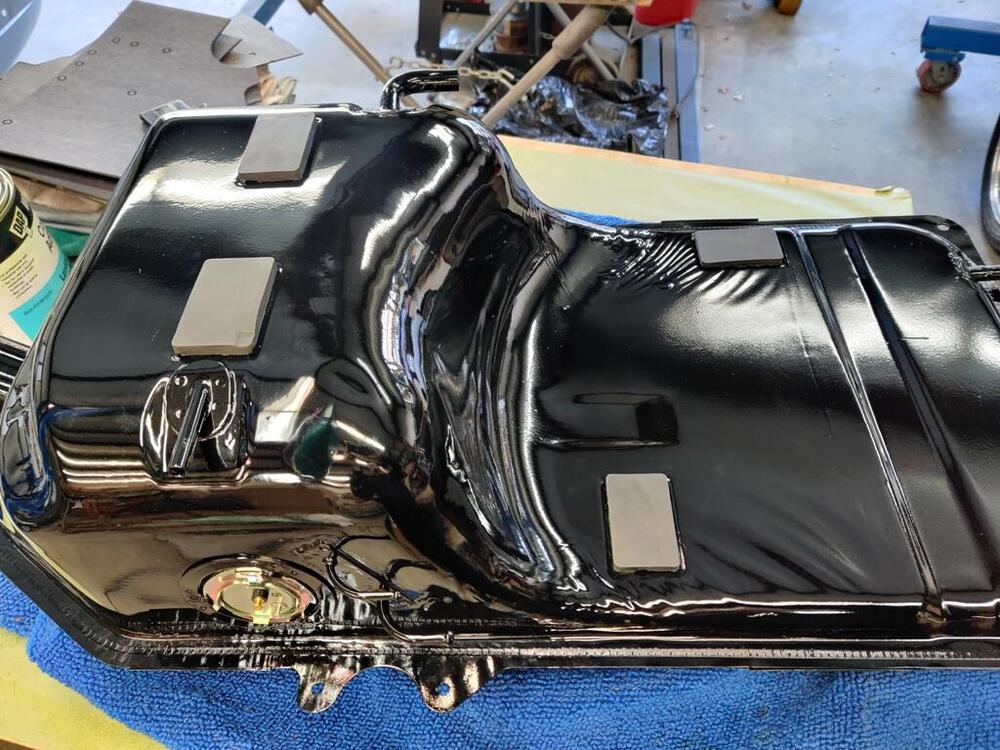

While I had the adhesive out, I also glued the rubber blocks to the gas tank and installed the new gas tank sender unit:

Subscriber

Subscriber 4Points1,282Posts

4Points1,282Posts