It's done! After a few weeks of tinkering around i had it finished. Well, actually, quite a while ago. But it's finally time to show you some details.

The kit took me approx 2 weeks of work every evening 1-2 hours. it's not too much of work, and pretty straightforward. the Manual is idiot-proof despite being in Japanese it's easy to make. The difficulty level is so-so. It will be tricky if you never used a screwdriver before. But for me, who didn't really have any experience with such kits it was doable. In my case the previous owner messed up a few things which i had to fix. The kit is intended to be only installed with screws (no glue!) but in some cases, it was nessecary to add some glue to make it more fixed. Some of the parts require quite some force to be installed, while being fragile at the same time. I broke 2 small things, but nothing a bit of superglue could'nt fix. At the end it's a super detailed model car of a Japanese Fairlady Z (with L20 engine). There is light, door light switches, brake pedal switches, many controls are movable (heater control knobs!), and it's pretty much close to the original car, from the chassis frames to all the engine bay and interieur details, it's absolutely incredible. It's a super fun project and well worth the hours spent:

Here arew a few details. Frame rails and front axle with steering rack installed:

All the lovely details of the L20 engine (yeah, you have to install every ignition wire manually!)

Rolling chassis with transmission Propshaft and engine installed:

Time for the interieur:

Here's an example of all the details. the battery alone is for e.g. 17 Parts:

And completed:

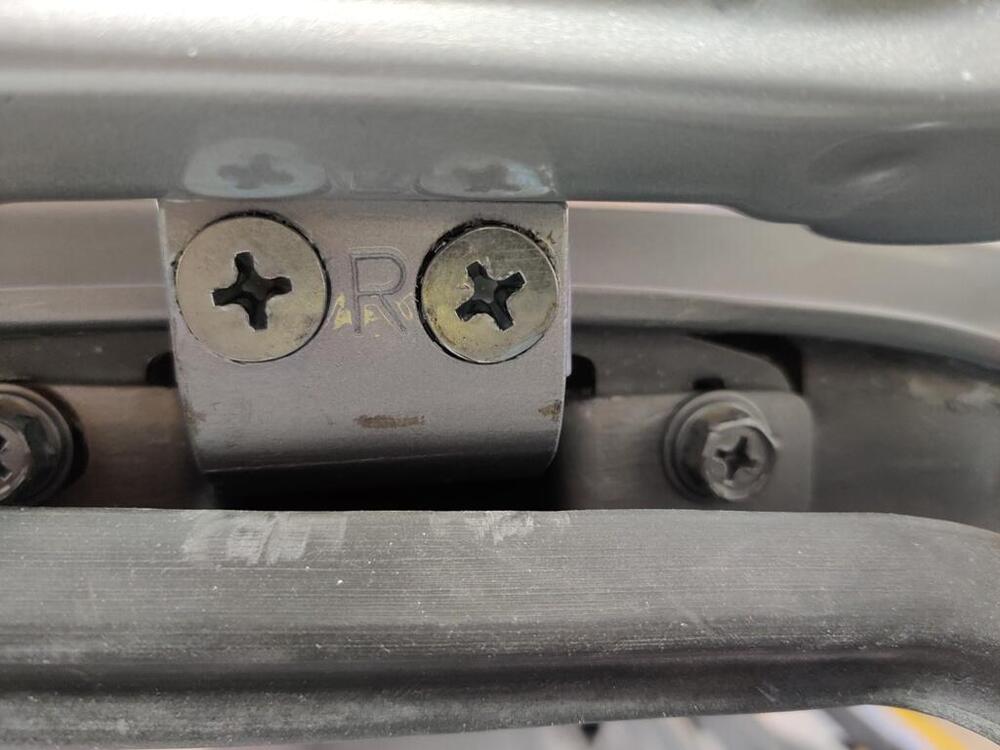

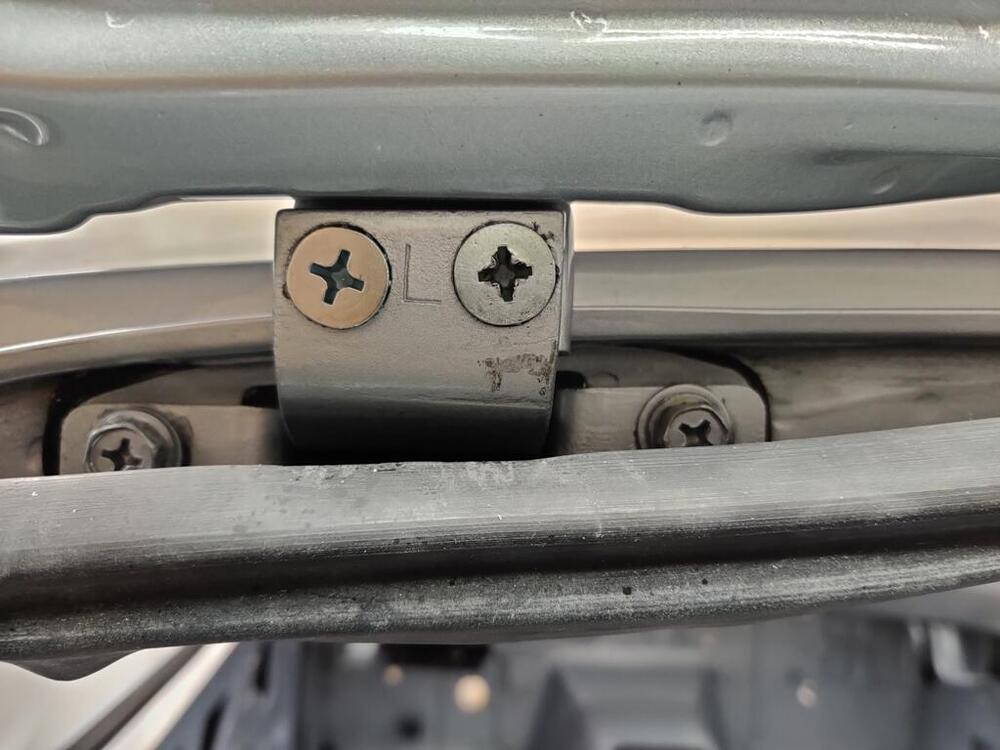

Or look at the hood hinge: Incredibly close to the original design 12 screws for one hinge alone!!

Some parts, like the door lock is as tiny as this:

The window have an actual working crank mechanism:

Body completed:

Time to put it all together:

This part was a bit tricky:

Batteries for the interieur, headlights, brake lights, etc:

And done, including the nice display stand:

The interieur is really lovely:

And all the details in the engine bay:

The tools and towel that came with the kit (original tool pouch got lost by the previous owner):

The spare screws, which are leftover at the end (each screw comes with at least one spare):

It's not going to be my hobby and i had to swear more than once, but at the end it was a super fun project with a really nice result. And the magazines, dvd's and the car itself are well worth it.