Yeah, it is not obvious which is the right torque value.

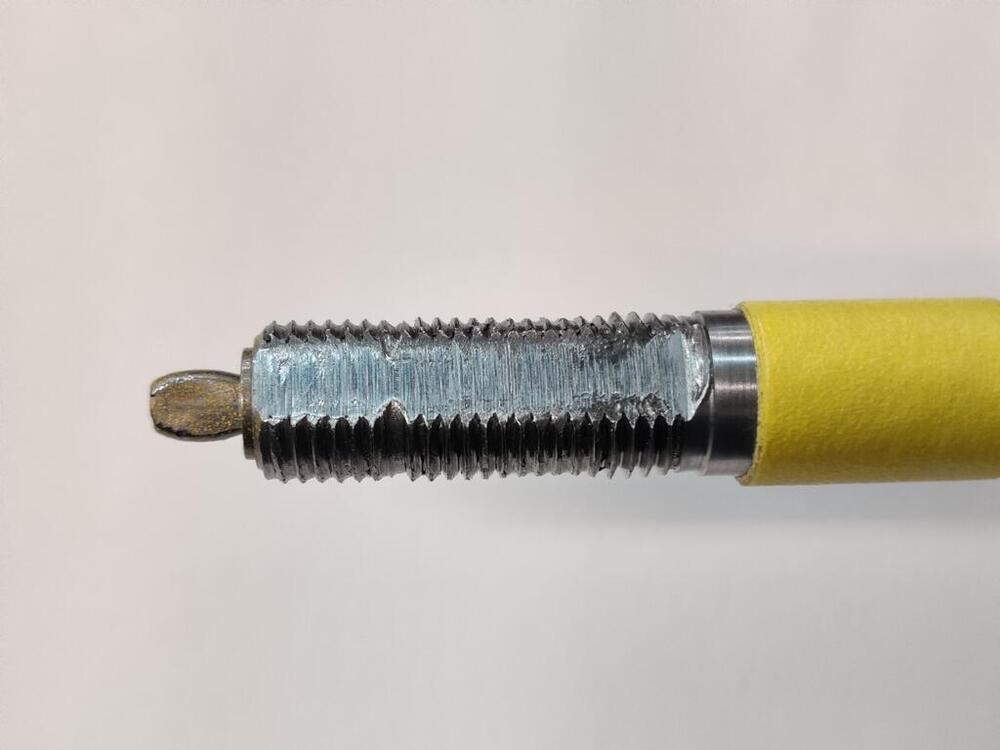

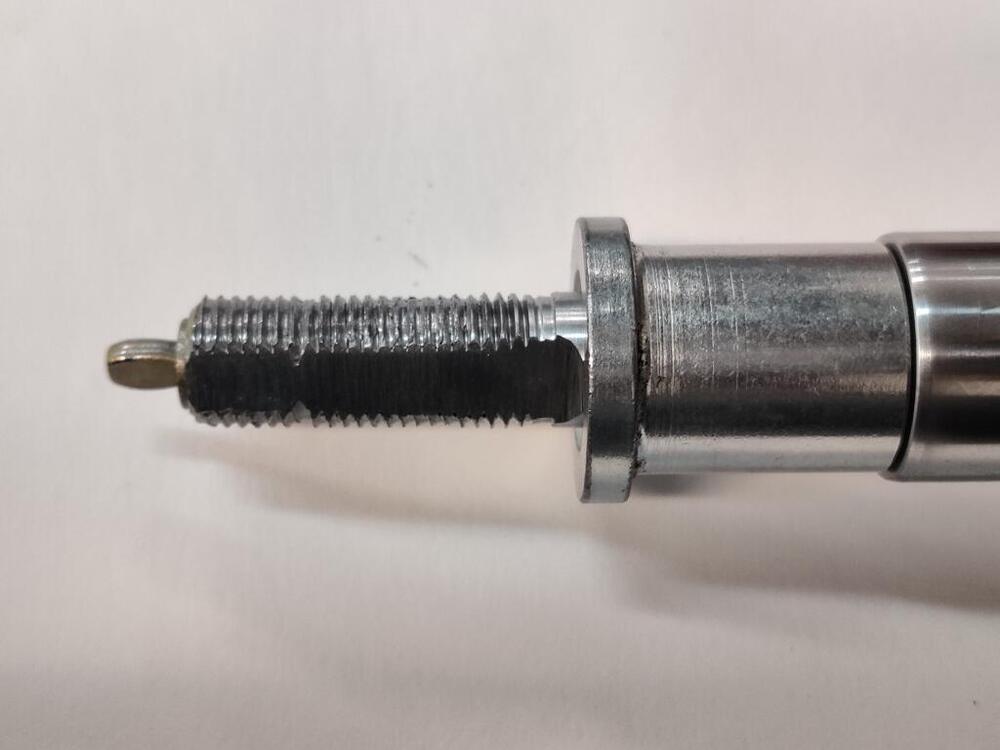

I decided to try to save the strut insert and spent a couple of hours giving careful attention to the threads. I used this tool which is for repairing threads:

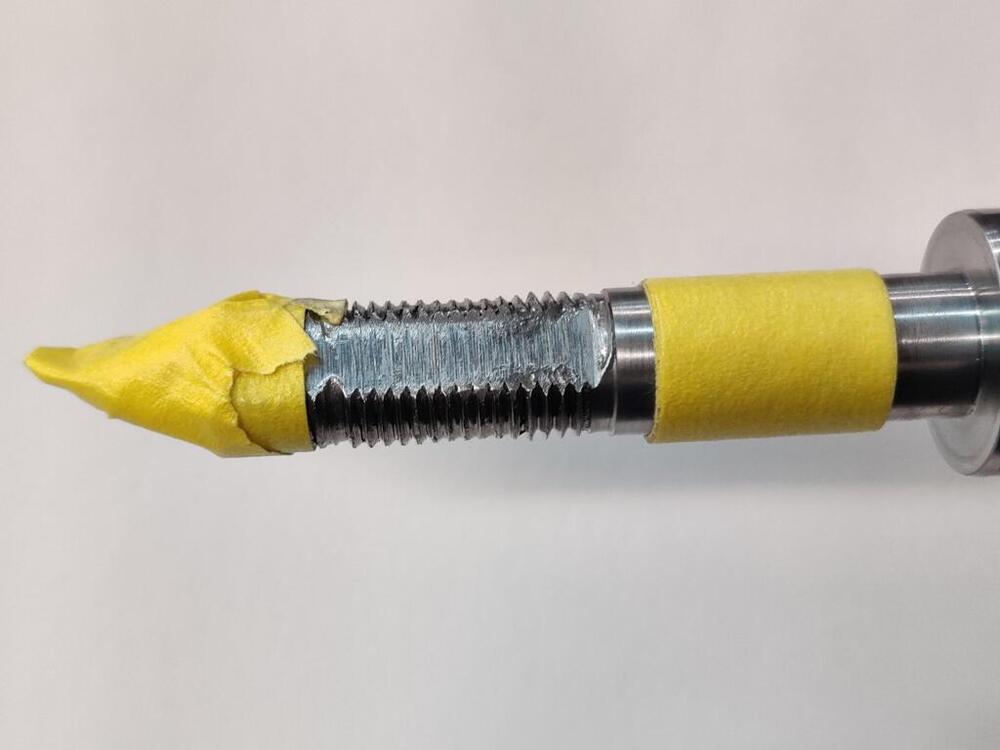

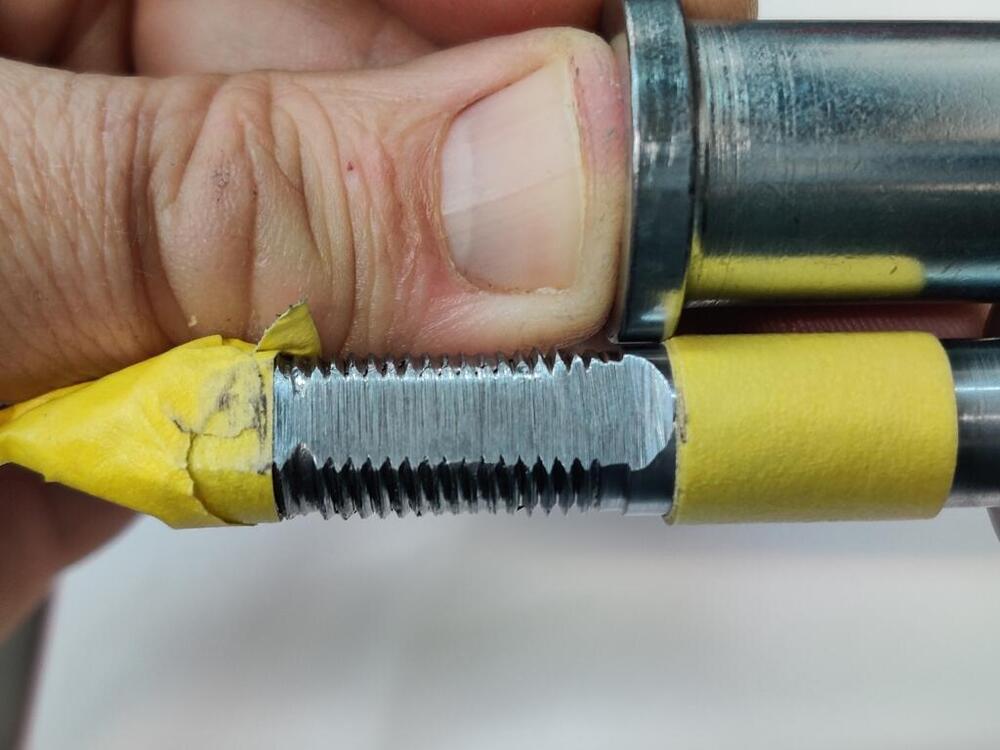

Using a lot of patience, I kept at it until the new coupler nut would thread on without difficulty. Here's how it looked after all that effort - these pictures capture how it looks all the way around the circumference. While not "great", the threads look better than before.

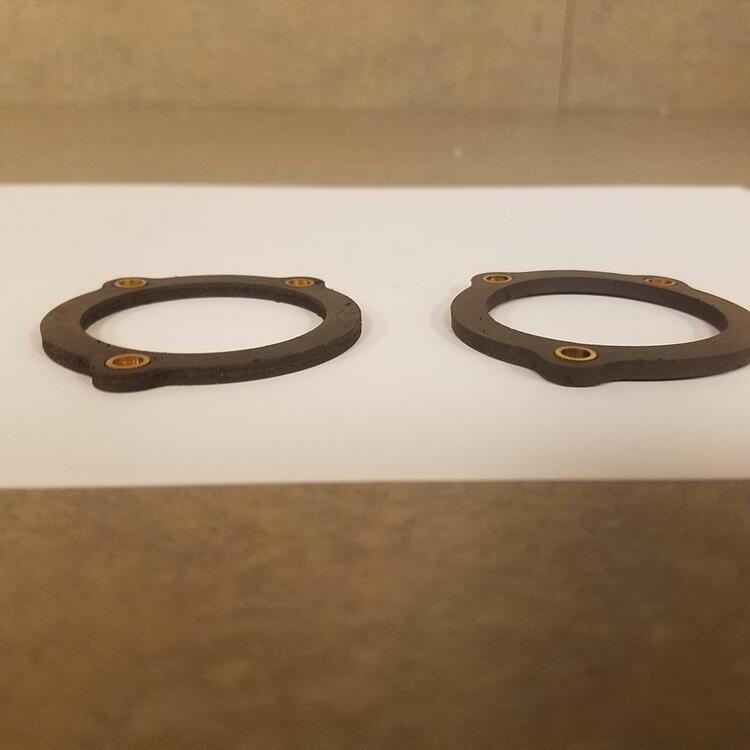

Also, note that the 4 to 5 threads just above the spacer (a bit more than a 1/4") were not mangled because the thickness of the isolator stacked on the spacer protected them. As I examined the situation, I determined that I could "alter" things a little bit, so I could utilize those threads. Basically, by shortening the spacer, the isolator can slide down further on the shaft and expose those threads to the fastener. I started by putting tape on the shaft to mark the area that I needed to grind to fit the "D" in the upper strut mount isolator. And, I taped off the adjustment mechanism to keep metal dust from getting into it.

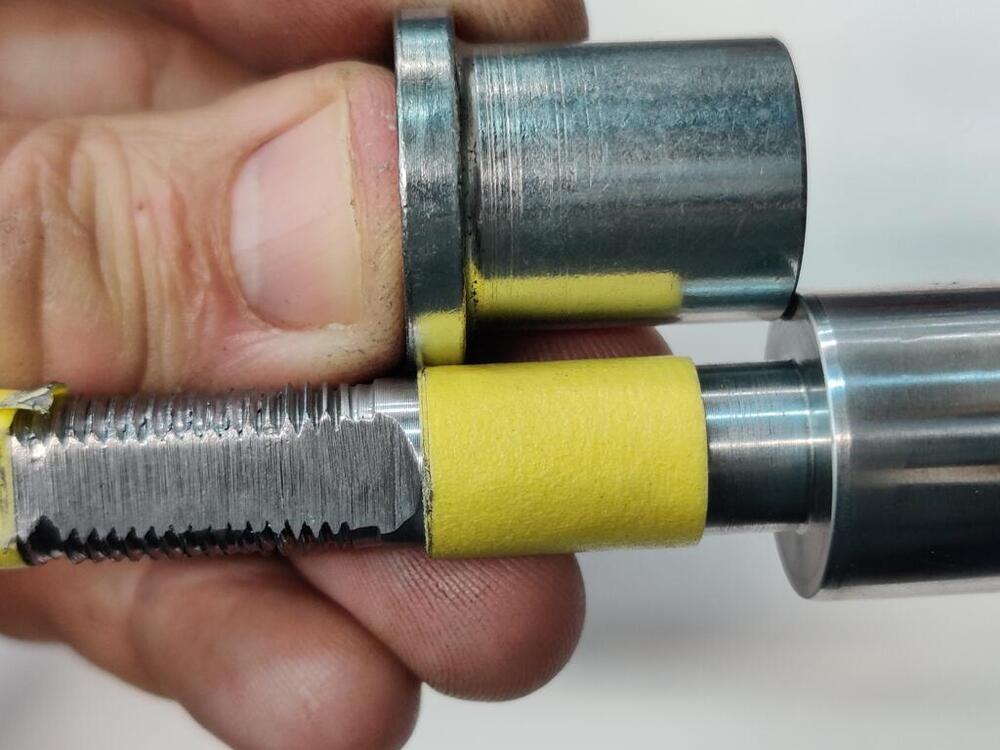

After using a belt sander to grind the "flat" in the shaft a little lower, I had to remove the same length of material from the bottom of the spacer. I don't have a lathe, so I had to be very careful with grinding. After removing some length, I very, very carefully used the side (which I have never used) of my 8" bench grinder wheel and kept measuring with vernier calipers until the cut side was square with the non-cut side. Then, I chamfered edges (middle pic). The shortened spacer length matches the shaft again (third pic here):

Final pics, with the third pic here showing the coupler nut after shortening it also.

I could have shortened the spacer and the nut a bit more to pick up another couple of good threads. However, given that the original nut only engaged about 7 threads, and this one engages more than double that (though some are in very bad shape), I felt grabbing those last two was not necessary.

Today, I assembled the strut, put it on the car, and used that same torque wrench to set the nut to 37 ft lbs without any issue whatsoever. I used a good bit of blue Locktight, which will keep the nut from backing off.

I plan to check the torque on that nut repeatedly as I put the first 500 to 1000 miles on the car. If it turns when retorqueing or feels odd at all, I will swap the insert for a new one.

Subscriber

Subscriber 3Points271Posts

3Points271Posts Subscriber

Subscriber 3Points1,282Posts

3Points1,282Posts