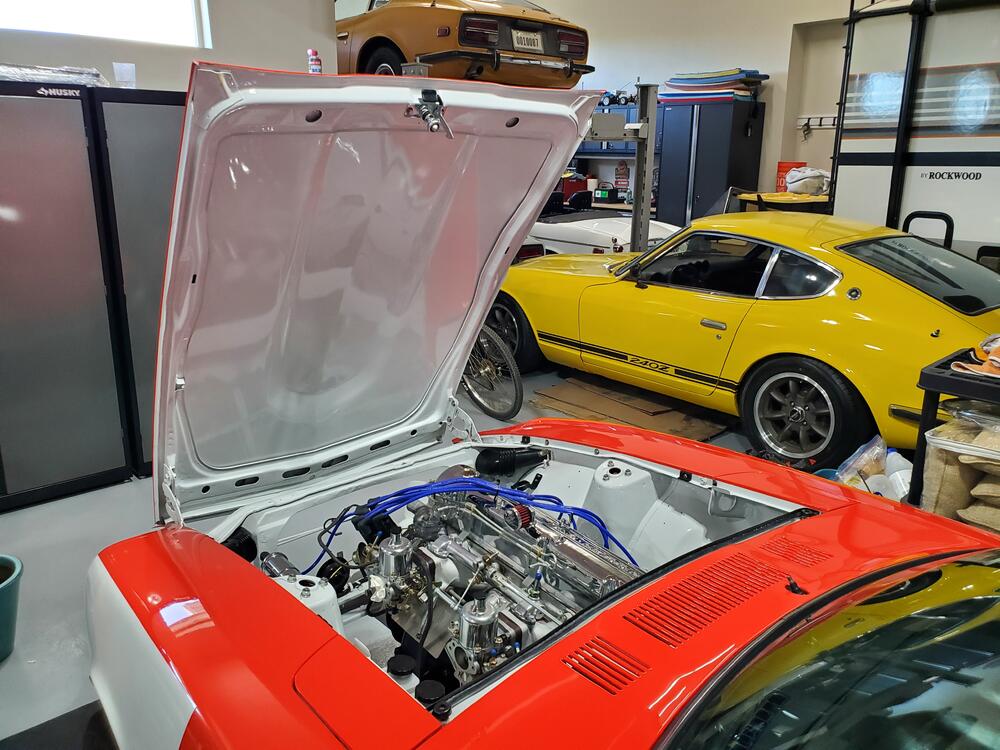

The paint job on this car is gorgeous! I love seeing this in my garage even though it is not mine. It looks right at home with my other cars. After a two year break, I am back restoring Z cars....in my retirement. I love it.

I did some of the work on this Z back in San Diego for a good friend of mine (the owner). I helped install the motor and transmission, all of the glass, most of the interior as well as the electrical harness refurb and wiper motor refurb. To make a long story short, I moved to Idaho, the owner is moving to Texas and not much has been done on the car since I left San Diego. I was asked to complete the build by the owner which I am more than happy to do. So, I will blog my progress on the site here for both the owner and others to see.

Some of the plans are to remove the current brake set-up and install the Z car garage set-up. Also, I will add air conditioning. I have done neither of these on my previous builds, but hope to get input from the group and installation videos as needed.

So, car arrived yesterday evening. We unloaded the car and pushed it into the garage where I will do the work. Today, I just wiped down the car with detailer and microfiber cloth to clean off the dust on the car and the engine bay, also cleaned the windows. I aligned the hood and latch mechanism so that everything operates smoothly. Tomorrow, I will begin to tackle the electrical wiring.

Most of the remaining parts are still in San Diego, but will arrive here in two weeks. Until then, I will clean up some of the items that are currently on the car. Here are a few pics

Subscriber

Subscriber 4Points11,142Posts

4Points11,142Posts