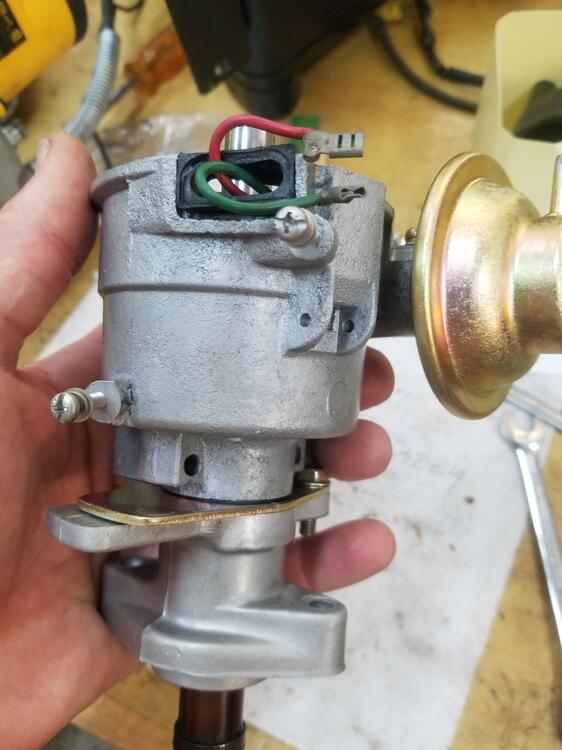

all done, hood back on, test drive complete, no leaks, runs very smooth, not sure if I can notice any performance pickup other than the smoothness, will have to get it out on a high way and really open up. Will take the cool running (90's today, and used the AC), and solid oil pressure. Now I will start the oil consumption testing. That was really the main reason, as I just was getting tired of the oil loss (qt per 800-900 miles). Should be interesting to see if any better. I also will hold off on tearing down the original engine until I get some time on this one, JIC something goes bad wrong, i can quickly replace it with the oil burner and not loose any drive time.

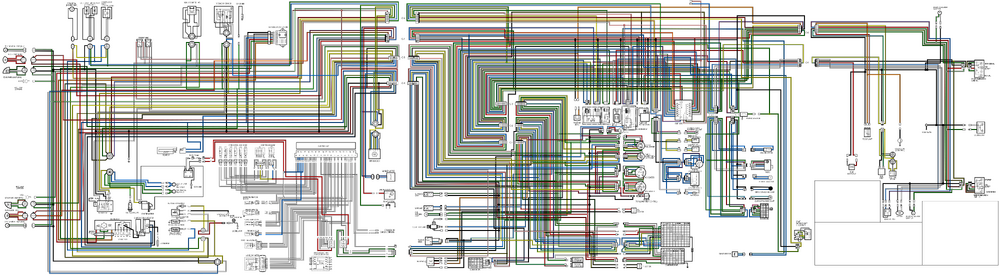

So long term plan will be to continue the wire harness mods for Plug N Play turbo, and a complete tear down of the original engine to see if there is obvious reason for the oil burning. I have hoping for stuck oil rings or clogged piston drain back holes. I will do an inspection for cylinder wear using the rings to check for any out of roundness. I did pick up some rings (std) just in case its not worn or damaged to the point of needing a rebore. All this is a ways off as I need to get some drive time in. Been too long since I had a nice road trip. Maybe up the east coast this time....

Subscriber

Subscriber 5Points3,770Posts

5Points3,770Posts

Subscriber

Subscriber 3Points1,336Posts

3Points1,336Posts