I bought a 12x12 sheet of closed cell silicone from Amazon that is the same thickness as the 240z gasket. I ended up changing the hole size on that from the sample and making about eight paper templates before deciding on a final one. An X-acto knife goes through that silicone like butter.

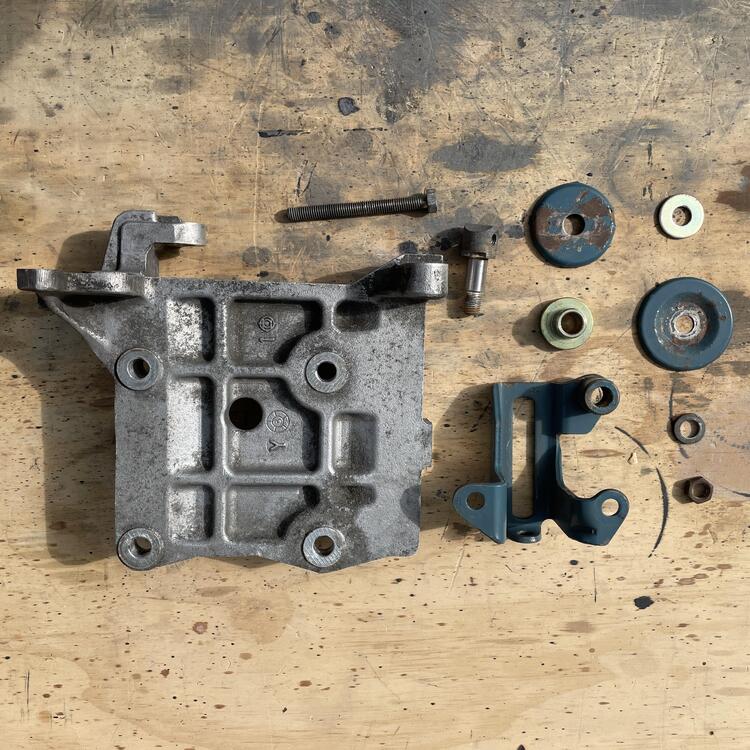

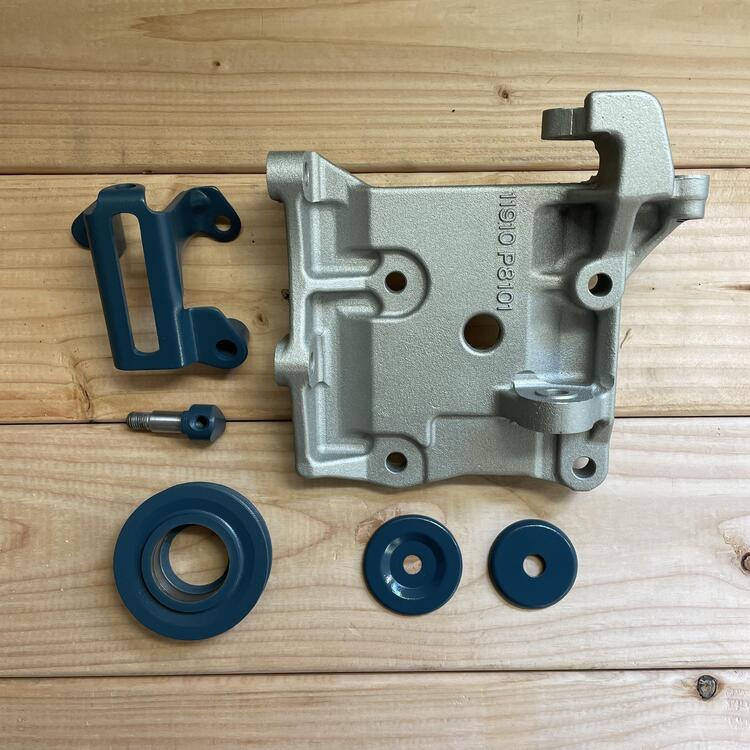

The ZX bracket was sandblasted and I used the same blue paint I used on the block, which I purchased from Motorsport. The silver paint is Eastwood Alumablast. I used a Timken 6203-2RS deep groove bearing (17x40x12mm). I have painted all of my aluminum parts in the engine bay. I have learned that radiator fluid additives can completely ruin the finish on nice aluminum parts so the only things I leave raw in the engine bay are brass and stainless steel.

For the quarter windows, I used Goo Gone to get them cleaned after taking them apart. The rubber is all new from Precision (not very precise, if you ask me). I polished the steel with Barkeeper’s Friend and then stainless steel polish. It has a faint brushed finish rather than a mirror finish, but that’s intentional.

The broken joints in the frame were glued with JB weld and clamped, because I didn’t feel like breaking out the welder for a single spot weld. However, the rubber, being not precise (see above), might have ruined that joint. I can’t completely tell and am not taking it apart to find out. It doesn’t matter because the car holds it together.

Weather strip is held in with black 3M weather strip adhesive and the various gaps were filled with black RTV. It looks like it’s supposed to be like that.