This thread is really nice , so much informative .

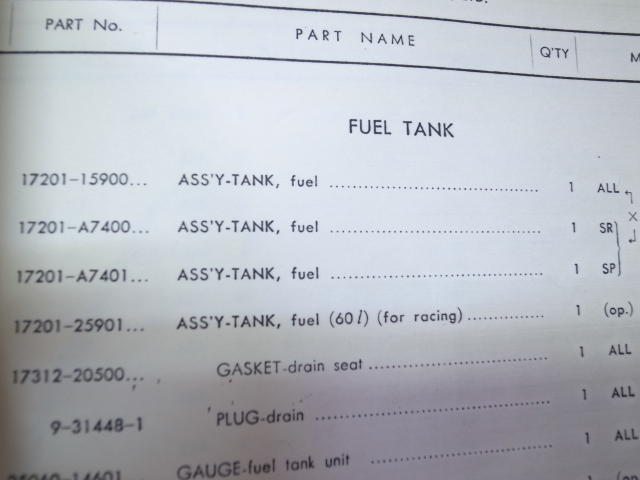

And finally I have got the answer to the reservoir tank of the Z432-R , the tank is exactly the same as our US and Canada early car except one tube is omitted by hand .

Pleae see the attached picture , you see the tube’s end is smashed , looks like heated by gun to melt the tube . I think we can say this tank is shared with our US and Canada tank , just one tube is different.

Not only this , the white front window screen , the fuel door knob, also rear deck rubber mat , side sill rubber trims ( left side is a bit different due to a foot rest ) are shared with export cars and Z432-R . Some of the items also shared with a Fairlady-Z , S30S ( Z-std ) .

BTW , this tank 17350-E7201 Tank-Reservoir Fuel 4.2L , 2000JPY is now on sale at Yahoo Japan auction.

Kats