Here's a summary with some reloaded pics.

Heater core for a 91-02 Ford Escort SOHC (not the ZX2). The heater core is aluminum, and the one I got was Spectra Premium P/N 94741. I decided on the Escort core because it was the thinnest, smallest, most generic, cheap core that I could find with tubes that stuck straight out on the same side. No long funky bent tubes. No weird mounting flanges. Generic, small, thin, and cheap because it's from a ubiquitous car and not from a low volume hard to find Ferrari.

Here's a pic of the Escort core next to the original 280 core:

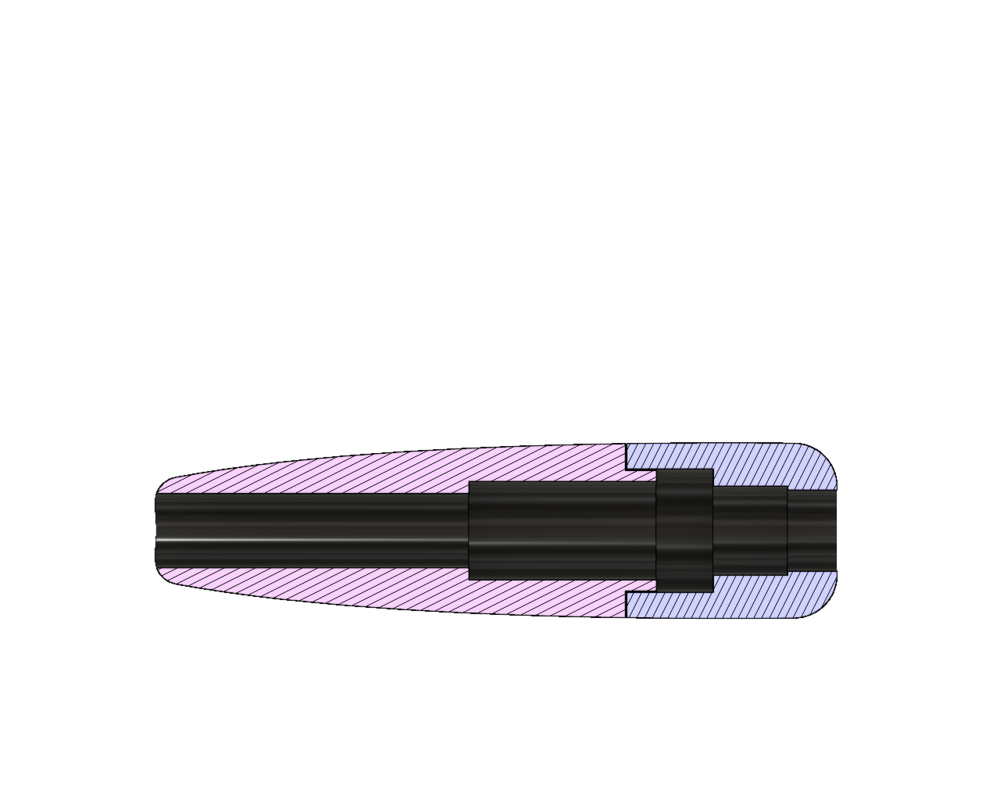

Escort core with a layer of foam around the outside for a snug fit inside the air box:

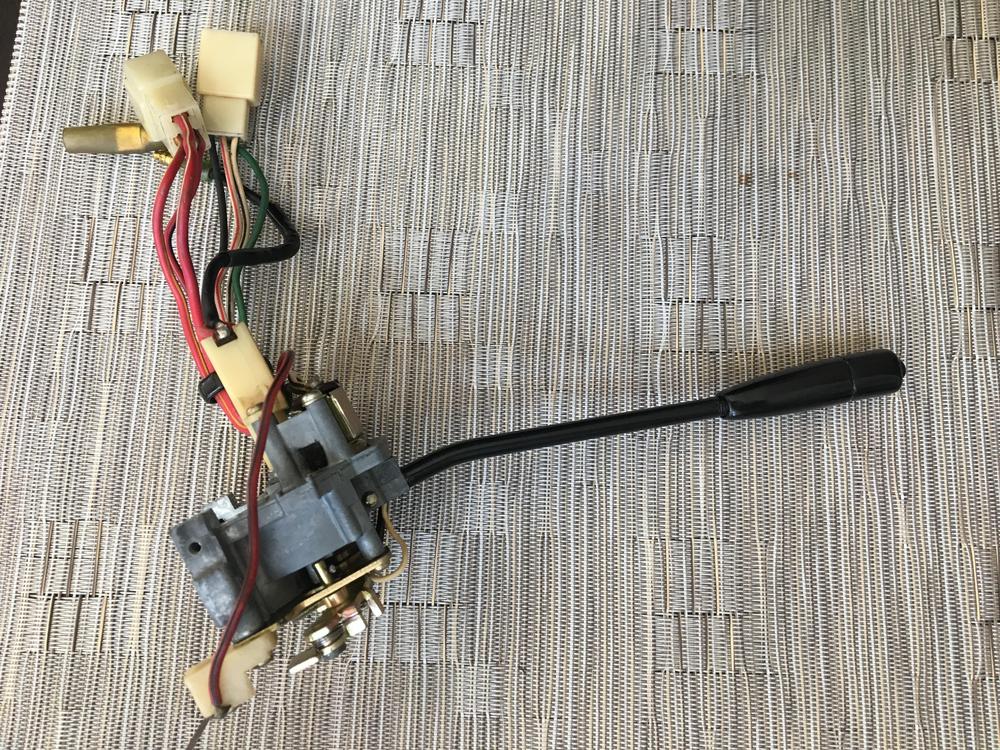

Build a little shelf for the Escort core to sit on. Since the Escort core is a little thinner, it allowed me to move the core up a little so it doesn't interfere with the floor duct control linkages at the bottom of the heater box (like the stock one does). Aluminum angle material screwed into place as a lower support shelf:

Escort core in place before putting on the access panel cover. Can't see it in the pic, but it's resting on the new aluminum shelf on the far side:

Cut some new holes in the access cover for the inlet and outlet tubes and put the cover in place. Tape over the original holes so air doesn't come out where it's not supposed to. I put a support shelf on the back side of the cover for that end of the core as well, but after doing that, I'm not sure it's really necessary. If I were doing it again, I would probably skip that second shelf and just use the inlet and outlet tubes poking through the cover as the supports on that end. But if you look carefully, you can see the heads of screws that hold the shelf in place:

When I get a couple more minutes, I'll post some pics on how to make water connection to the core.

Subscriber

Subscriber 2Points2,228Posts

2Points2,228Posts