Been working on getting the car going for a few weeks now.

Was ready to fire it up last week, tried to jump it. But the battery was obviously far too gone to even jump. I didn't realize a battery could be too dead to jump, but apparently it can.

New battery, new starter, new cap and rotor.

Still nothng. Checked for fuel pump noise by unplugging starter terminal. Pump was running. Fuel had gotten to the filter up front (I cracked open the clamp).

Checked for spark at the coil and at the plug wires with a multimeter and then a timing light. Have spark.

Found TDC. Here was the problem:

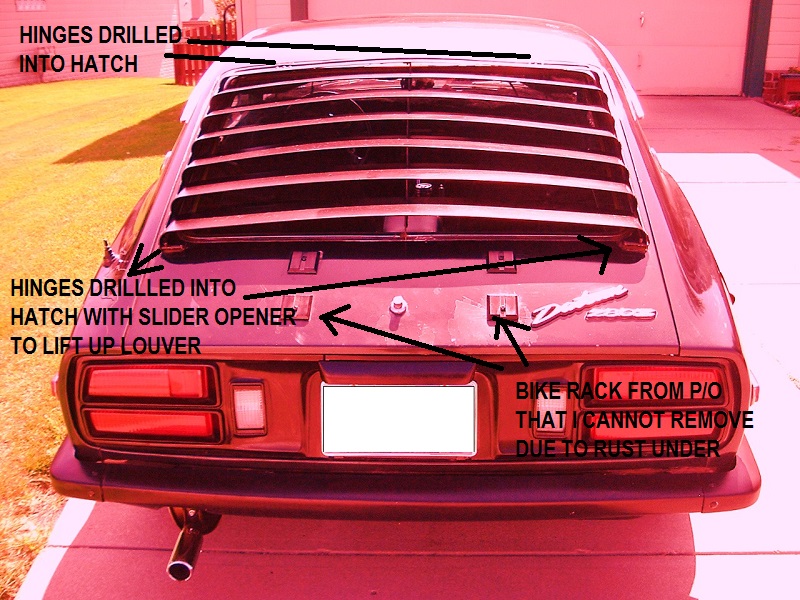

The Chilton's manual shows the #1 plug terminal on the rotor as being the one under the clip, which is one too far down. That is why I could not get the rotor to point at #1 when at TDC. As seen in the image below: (firing order is correct, but the distributor terminals look off to what they actually should be)

After researching online, it appears that the #1 plug terminal should be the one just above or at the clip, front most in the car. Anyone else noticed this in the manual? It threw me off for awhile.

Once I swapped the wires one position "up", it fired right up! Pretty smooth, but does still need some tuning and work:

Lots of smoke coming from the exhaust manifold. I think I missed a bolt or two.

Also it appears to have no brakes. Fluid is full, booster is connected. No pressure on the pedal though.

Auto trans is slow to engage also, but probably just a fluid or adjustment issue. It shifted fine before.

The valve train seems kind of noisy though, but it seems like these cars sound like that normally?

Anyways, I have time before I drive it, but it way a HUGE milestone for me, as I've never installed an engine or done work of this extent before. It was also 3+ years ago since the car ran. It made me happy for a minute. At least I know the engine runs...