Everything posted by Namerow

-

Can you replace headlights without taking of headlight bucket?

My all-time favourite Bondo Queen was a Ferrari 275 GTB that appeared on the FerrariChat website several years ago. It looked so-o-o-o pretty (and cost the new owner about $1.5 Million at the time to make the pivot from 'just shopping' to 'proud new owner'). Nevertheless, he decided to commission a shop to make it 'even better' (including new paint, of course). Unfortunately, when the shop started to prep the body panels for said new paint job, they discovered evidence of filler in places where it shouldn't have been. Digging deeper (literally), they found that the entire nose was nothing more than Bondo. Up to 1" deep in many places. More exploration (excavation?) found deep pockets of damage that made one think that the car had fallen off the top level of an auto hauler and landed on its roof. The shop was stunned by quality of the bondo slinger's work, calling him an artist. When we made the transition from horses to autos a century or so ago, the method of transportation may have changed but the same shysters stayed loyal to the cause and moved from 'horse traders' to car retailers without losing a step.

-

Z Restoration Progam

Interested -- if the price is manageable.

-

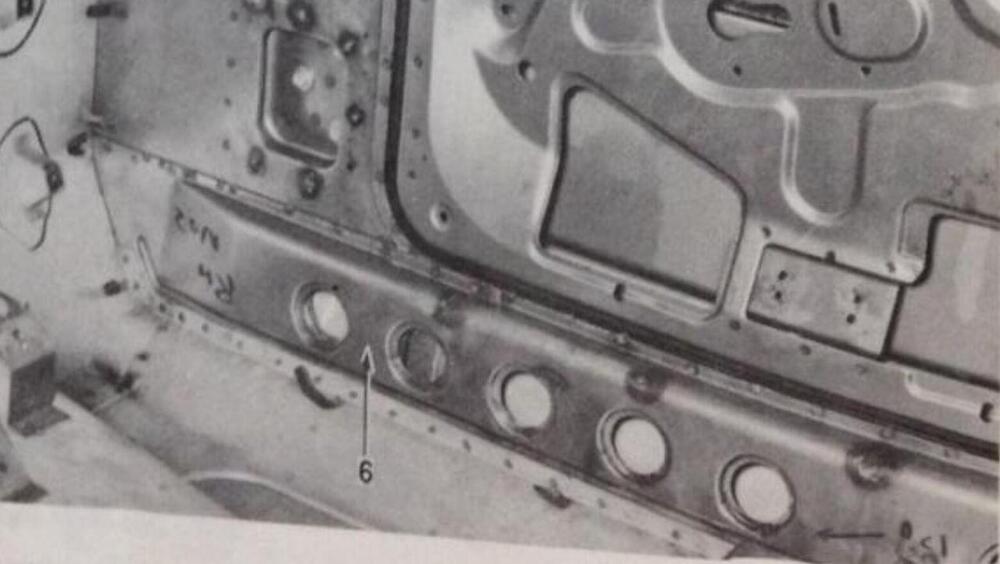

280 Factory floor pan welds

Refer to the figure below (taken from the FSM), which shows how the inner and outer rockers and the floor pan come together. The arrow on the outboard flange of the floor pan shows how the flange aligns with the inner rocker. Note the horizontal rib (with the 'hockey stick' shape at the forward end) that's pressed into Inner Rocker ('Inner Sill). The top of the Floor Pan's outboard flange (designated in the figure by the small black circle) should align with the lower edge of the rib. The line of spot welds that joins floor pan to inner rocker sits about halfway up the floor pan's outboard flange (see photo).

-

Saving- 04858

Also: Please discuss your technique(s) for separating spot welds.

-

Saving- 04858

How did you close that .25" gap?

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Nice-looking property. Definitely what every buyer hopes for when they read, 'Treed lot'.

-

240z Complete Replacement Shell - The Ultimate Rust Repair Panel

I'm not convinced that this is 'the real deal'. Consider what KF Vintage offers in the way of replacement panels. It's a pretty extensive list, but when you put them all together your still missing (rough guess) 33% of a complete unibody structure. Is anybody really going to tool up to produce the Z's (complicated) A-pillars? And what about the rear floor and rear frame rails? And the (complicated) front cowl structure? And the (complicated) rear hatch sill structure? My guess is that we're looking at a KF Vintage-like collection of replacement panels being bannered as a replacement unibody structure.

-

SN 00042 Restoration; The Older Twin

The 'rotisserie' set-up is intriguing. It looks like it may do a better job than conventional units when it comes to keeping the unibody structure unstressed as it goes through rotation, but... it looks like a right PIA to cut and install all of the necessary support links. In addition, the roll-over hoops are in the way all the time, whereas a conventional rotisserie has no such blockages.

-

240s showing up

It's a remarkable bit of production. Kudo's to Nissan Canada for financing the project, and to the Canadian ad agency for designing and realizing a killer advert that properly and expertly recognizes the significance of the Z's role in creating Nissan's worldwide market presence (notwithstanding Nissan's Japan's efforts throughout the 1970's and 1980's to throw it all away). Additional kudos to Nissan Canada for providing its corporate facilities in Mississauga, Ontario as the venue for the annual show-and-shine meeting hosted b y the Ontario Z-Car Association (look it up). I'm really proud of Canada's (continuing) role in supporting the Z legacy. Here on CZCC, I would draw your attention to the importance of our Canadian members in making this site such a valuable Z resource. Those who come immediately to mind are 240/260/280Z (who's written a complete library of Z rebuild articles), along with Grannyknot, CanTechZ, Wheee and zKars (some of the best restoration build contributors that this site has enjoyed). I should also mention that, for years (dating back to 1994), Charlie Osborne at Zedd Findings in Kingston, Ontario, was (I believe) the only source worldwide for decent replacement Z floor panels and front frame rails.

-

240s showing up

The ad was produced for Nissan Canada to celebrate the 60th anniversary of their entry into the Canadian automotive market. Stunt driving was performed by Kiwi rallycross driver Rhys Millen (son of Rod, nephew of Steve), using the airport at Lillooet, British Columbia for an action shot that was then blended into the primary road footage (shot on a nearby highway). There's a short feature on the video shoot available on Facebook... https://www.facebook.com/nissancanada/videos/781763657583093/ The actual video can be found on the landing page of Nissan Canada's consumer website... www.nissan.ca (scroll down on the landing page to find the video). I don't think it's available on YouTube yet. Nissan Canada's corporate media website has some nice feature articles and photos built around the 60th anniversary celebration... Official Canada NewsroomNissan Celebrates 60 Years of Innovation and Excellence i...Nissan Canada Inc. is proud to celebrate its 60th anniversary, marking six decades of innovation, growth, and commitment to the Canadian market.

-

240z Complete Replacement Shell - The Ultimate Rust Repair Panel

Fascinating. I wonder if it's real.

-

Restoration of BringaTrailer 240z - HLS30-35883

I've just re-visited this 2020 post. In hindsight, I think this may be the definitive photo essay on the design and construction of S30's 'dogleg' structure. I wish they all looked like this but, as Inline6 notes, the structure is completely missing on far too many Z's (replaced by bodge and newspaper, topped with a Tabco panel). If your Z isn't sound in this area, don't count on your lower seat belt mounts (yours and your passenger's) if you're involved in a collision.

-

Hole help

We need more, and better, pictures to answer your question. I have a couple of theories, but I'm going to wait until I see better photos.

-

Hatch drip gutter extension

Worked for Grannyknot using zero-forgiveness sheet metal. I don't see the problem.

-

Hatch drip gutter extension

Even though Grannyknot made his gutter extensions out of sheet metal and welded them into place before applying his the final paint coat, you could just as easily fab up something similar and just glue them in place. Make them out of 'L'-section plastic (hobby store) to address rust concerns and paint them body colour before gluing to the hatch body sill.

-

08/74 260Z Project Planning: Floor Panels Before Rockers?

I'm hoping that you acquired this car on the cheap ($2000 or $3000). If that's the case, I would respectfully suggest that you write this one off as a learning experience and go back into the market to find a better example. This one looks like it's going to be a long, painful and costly experience to turn it into a vehicle that you'll enjoy. Without looking too hard, it's clear that this car is going to need: floors, seat supports, inner and outer rockers, rebuilt dogleg structures (seatbelt mounts), underside floor rails, rebuilt inner fenders, rebuilt lower doors, rebuilt lower front fenders, and rebuilt inner/outer rear wheelhousings and rear quarter panels. I suspect it may also need to repairs to the front cowl area (complicated and challenging) and the rear hatch slam panel area. It may even need front frame rails. And the A-pillars could be rotted out at the top and/or bottom of the windshield. After that, you'll probably need to put $2K - $3K into the powertrain and another $2K into the suspension and steering. Add at least $5K for paint. With all this in mind, you're probably at least a year away from having the car on the road. Or longer. Or you can go out and buy a decently restored 260Z for something in the $20,000 range and start driving it right away.

-

My Listing: Authentic OEM Nissan Fairlady Z/Euro 70-78 Datsun 240z S30 Headlight Covers

Not quite a unicorn... but pretty close. Current bid is $205. I predict it'll take over $750 to buy these.

-

Bodywork Issues

Hmmm. Not sure if this will help, but: OEM weatherstrip often makes strategic use of 'rubber stuffing' (technical term -- I just made it up) at locations where the strip has to make a tight bend. It's put there to keep the hollow section from collapsing (which would possibly lead to unwanted wind noise or water ingress). You can't see it. You'll only know it's there by doing a pinch comparison at selected locations along the length of your the weatherstrip. I found it in both the Kia Sportage and Nissan Altima weatherstrip that I experimented with. The 'stuffing', as used, was ~ 4" - 5" long. I wonder if the aftermarket suppliers are doing the same thing? p.s. I used the front-door weatherstripping from a late-1990's Kia Sportage for both my doors and hatch. Very happy with the results.

-

New Nissan Canada commercial

Nice ad. If they did it thoughtfully, there might also be promotional value in highlighting two other successful Datsun models from the early 1970's: the 510 sedan (contrast with Rogue), and the 520 pickup (contrast with Titan). Not too many buyers in 2025 realize that the pecking order for Japanese imports back then was Datsun-Honda-Toyota, rather than today's Toyota-Honda-Mazda/Subaru. The decision to re-brand from 'Datsun' to 'Nissan' (1977?) was such an unnecessary a disaster. The bland-mobile 1980's models didn't help either.

-

Chassis Dimensions and the BF-3 PDF

I have also used a plumb laser to do frame measurements on my Z. I began by taping together a bunch of poster board sheets to form a single big rectangular sheet that was long enough to go from bumper to bumper and wide enough to just fit between the inner sidewalls of the tires. Once I had it in position under the car, I taped it to the garage floor so that it wouldn't shift while I was lying on top of it taking sightings on the various targets. Once I got the laser aligned with a target, I used a Sharpee to make an 'X' mark on the sheet (along with a little note to record what target it was for). After I had marks for all of the targets, I pulled the sheet from under the car and laid it out on my workshop floor so that I could make the various target-to-target measurements with a tape measure. This system works pretty well for most the undercar measurements. The car can be sitting on its tires, but it needs to be elevated a bit (I used wheel dollies) so that you'll have enough room to slide underneath. However, it won't help you with the fore-aft locations of the shock towers unless you remove the struts and sight the laser down through the hole in the centre of each shock tower cap (the procedure for this is to put a piece of wide masking tape across the hole, trace the hole outline with a pencil, mark two intersecting centrelines, and then poke a small hole at the centre point for the laser to shine through). You'll also need to set up some kind of the platform above the shock towers (I used a length of 1 x 6 lumber) to give you a perch for the laser to sit on. Additional requirements: You'll need to get the car up on axle stands. Don't do any of your measurements until the car is up on the axle stands. You'll need to get the lower control arms out of the way b/c they'll block the laser beam from reaching the floor. This isn't too hard to do at the front (the LCA's can be folded up to a near-vertical position after the struts have been removed). I'm not sure whether this can be accomplished quite so conveniently at the rear (I didn't try). It might be necessary to actually remove the lower control arm from the car ☹️.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Even though you put a ton of work into fixing up your old garage, I guess it wasn't too difficult to leave it behind in return for a clean, modern garage already equipped with a good floor, good lighting and three bays (not to mention a separate, two-level barn for storing panels and parts. 👍

-

Chassis Dimensions and the BF-3 PDF

The reference points used to generate that 913mm measurement are tricky to replicate in practice. If you look closely at the small sectional drawing of the front shock tower, you'll see that the 'A' point actually lies on the plane defined by the underside of the shock tower cap. You can't measure at this plane unless you remove both front struts and then use either a trammel bar or a plumb laser. So, instead, you have to measure across the tops of the shock tower caps. But... Not so apparent from the sectional drawing, but very clear to the naked eye, is that the shock tower cap has a lip on the top (this is a little more evident in the sectional drawing of the rear shock tower that appears on the right side of FSM Dwg. BF-3). The top of this lip sits (by my measurement) 13mm above the bottom (reference) surface of the cap. So when you take the 13.5-degree cant of the front strut into account, it means that if you measure the A-A distance at the top of the lip, the result it will be somewhat less than if you were measuring at the (intended) bottom surface of the cap. My calculator says that 'somewhat less' = 7mm, so a measurement of A-A taken across the top of the lips should be 906mm. Now, if you left the press-in black plastic trim buttons in place (did you?) and took your measurement across the top of the buttons, you'll be measuring at a plane that's even higher above bottom (reference) surface of the shock tower cap. 906mm will shrink to ~ 902mm (est). Also: It's difficult to make this measurement accurately with a steel rule or (worse still) a tape measure. The correct way is to use a trammel bar*. If you used a steel rule or tape measure, your measurement accuracy will be no better than plus/minus 1mm (and more likely only plus/minus 2mm). * You can make your own single-purpose trammel bar. Start with a 4-ft (1219mm) length of 1" x 2" lumber and two 6-inch lengths of straightened 0.032" wire. Drill a slightly undersized hole into the flat side of each end of the wood strip (drill all the way through) and then press the wire lengths into the holes. The holes should be about 900mm apart. Now, using 1-qt paint cans sitting on each front fender, support the wood strip (your 'trammel bar') above and across the shock towers. Adjust the projecting length of the wires as required. Then line up the tip of the LHS wire with the centre of the LHS shock tower trim button. Then -- taking care not to disturb the trammel bar -- bend the RHS wire until its tip aligns with the centre of the RHS shock tower trim button (you may need to go back and forth a bit, until you're satisfied that both wire tips are correctly aligned with the centres of the trim buttons). To get your final measurement, transfer the paint cans and the trammel bar to your shop bench (don't disturb the wires!). Then position a steel rule on the bench top so that it sits under the wire pointers and take your measurement.

-

Chassis Dimensions and the BF-3 PDF

Is it possible that you've misinterpreted the reference point for the 465mm measurement that appears in FSM drawing? The way I read the drawing, that 465mm measurement defines the distance from the so-called 'C-point' to the centreline of the moustache bar's chassis mount bushings (if you look really closely, you'll see the moustache bar's circular end loops defined just to the rear and inboard of the rear shock tower chassis mounts). Let's call this location on the vehicle the 'E-point'. The 'D-point' refers to the centreline of the top of the rear struts . But, according to the FSM drawing the centreline of the top of the struts lies directly above the centreline of the 'gearcase mounting rear crossmember' (which is a more useful reference point when taking measurements off the vehicle). The D-point sits 450mm aft of the C-point The E-point sits 15mm aft of the D-point (so 465mm aft of the C-point). The photo below (source?) provides a good visual reference for what all this looks like on the underside of a bare Z structure. As far as I can see (I could be wrong), the FSM drawing makes no attempt to provide dimensions for the location of the rear lower control arm and its mounting points. You'd need to construct your own layout drawing for the diff, moustache bar, and rear suspension in order to specify (in mm) the locations of the rear lower control arm and its mounting points relative to the C-point.

-

Not dead...yet (Hi from Blue)

Great to have you back on board, Phil. Your how-to articles, posted both here and on the Atlantic Z site, have remained an important resource for all of us Z owners.

-

Saving car #34464

You did a great job, with both the car and the build thread. Thanks for the update. We now have closure! 😄

.jpg.f37b355fb0f6aaf74a4462f4b0712165.jpg)