Everything posted by Zed Head

-

Wanted ECU?ECCS for Euro 1983 280zx Turbo (and diff between those from EU and USA model!)

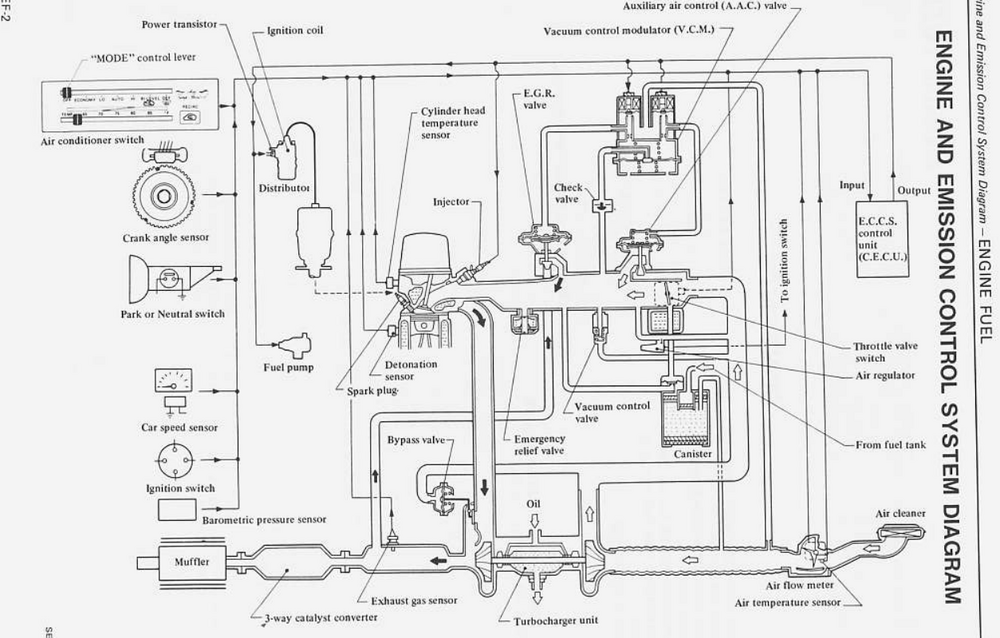

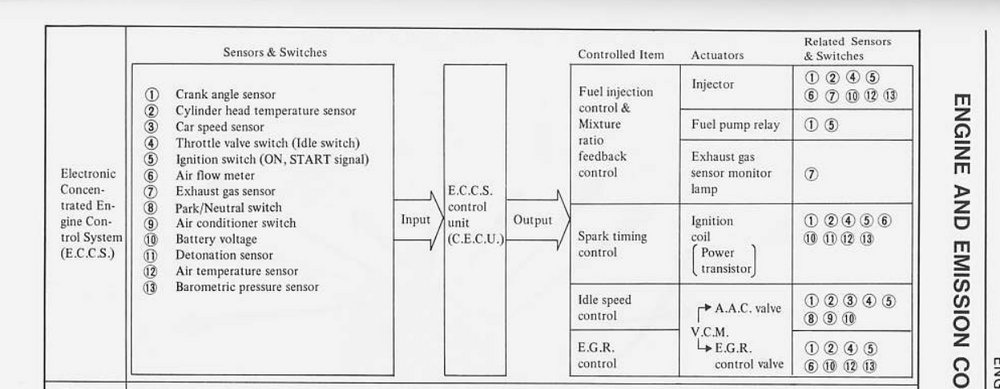

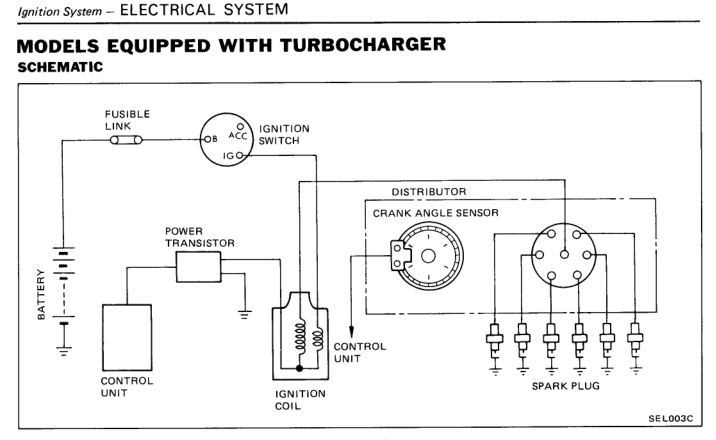

That's a 35 pin NA connector on a United States car. Maybe the ECCS system was only introduced for emissions purposes in the States. I don't see how ignition timing control would work though, since the ECCS controls that using the CAS in the distributor. Any chance that your friend has made the not uncommon mistake of confusing the injector cooling fan with a turbocharger? Maybe it's not a turbo car.

-

Wanted ECU?ECCS for Euro 1983 280zx Turbo (and diff between those from EU and USA model!)

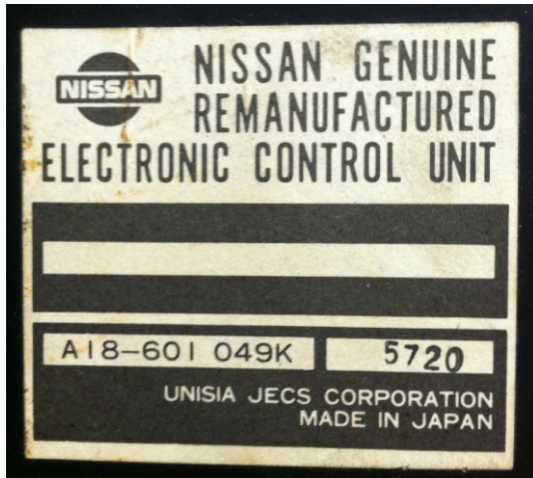

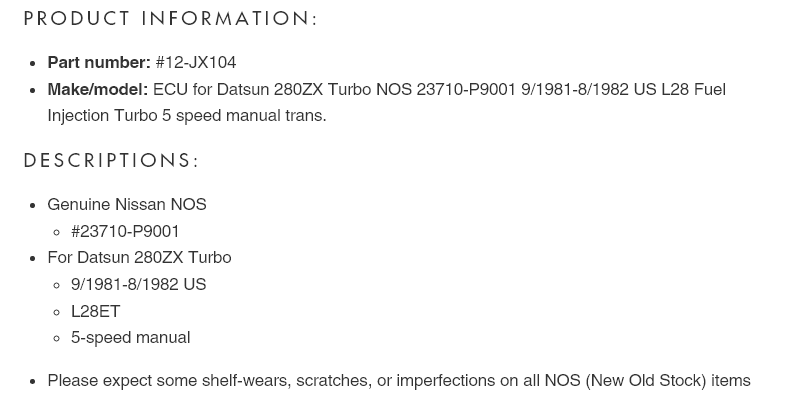

Will not fit or will not work? Check the FSM wiring diagrams. Get some part numbers. https://www.zdriver.com/forums/fs-240z-260z-280z-280zx-70-83-242/82-280zx-turbo-ecu-nissan-remanufactured-unit-35890/ https://maseraticompound.com/products/datsun-280zx-turbo-engine-ecu https://jdm-car-parts.com/products/ecu-for-datsun-280zx-turbo-nos?variant=744994189

-

What's your opinion of California Datsun Chrome Round Mirrors?

-

What's your opinion of California Datsun Chrome Round Mirrors?

Motorsport Auto has a good selection. Probably cheaper and of higher quality. The Classic mirrors are actually 60's Mustang mirrors. I had a set. They fit well and I liked the look but they were noisy in the wind. You could hear them with the window open. One of those things that you don't really think about. https://www.thezstore.com/product/926/classic-chrome-mirror https://www.thezstore.com/isearch3?searchterm=mirror

-

What valve specs y'all like for adjusting

That is a cool tool. No more fiddling around with two different gauges. This thread has the spectrum from cold adjustment, take-your-time and get it right, up to hot, I-know-what-I'm doing get it done.

-

What valve specs y'all like for adjusting

The low clearance could be because the valve seats have worn. Maybe due to unleaded fuel on old seat material. People use brute force on the locking nut with a wrench and suffer busted/cut knuckles. The parts up there are sharp. I found that a small sledge hammer, like a 3 lber, used to tap on an open end wrench on the lock nut worked well for loosening. There's room for an open wrench on all of the locknuts, you don't need the crow's foot adapter unless you want to get precise on tightening torque. It's about as simple as it looks. There's a threaded stud with a locknut. Loosen the locknut, turn the stud, tighten the locknut, confirm lash. After a few you'll realize that tightening the locknut pulls the stud up and reduces clearance a little bit. There's a tutorial out there somewhere with pictures. Can't remember the name, it might actually be linked in this thread somewhere.

-

Restoration of BringaTrailer 240z - HLS30-35883

I used a vise, a socket, some fixturing, and a MAPP torch. I've always been surprised at how much effect heat has. Apply force, nothing, apply heat, movement, let cool, nothing, re-apply heat, keep going. It's been the same on broken off studs. And differential fill plugs. Heat is your friend. Even on the mustache bar bushings you can get the rubber out by heating the outer metal of the bar. A little bit of sizzling and it slides out. No need for flames and smoke.

-

resurrecting a 1977 280Z

Wow, that is great sound. "Rebello stroker" has just been words on the video screen until now. Looking and sounding good.

-

280Z fusible links

I put a separate single terminal under the relay cover (the one right in front of the battery) to use for attaching separate relay wires, and the EFI power supply wire. Also moved the alternator charge wire to it. Ended up with a stack of ring terminals on the single post but they stay clean and dry, unlike the other places that they were attached. If you decide to use relays for things like the headlights or marker lights like I did you end up with no convenient place to attach to the system. Plus, once I cleaned up the positive battery post it was easy to use one of those plastic post covers to keep it dry. If I was starting over, I'd probably get a box like Hussein's with a few extra terminals. And the reversed battery posts, of course, to bring it out from under the fender. Or mount the box on the relay cover and just run a short charge wire over to the battery post.

- 280Z fusible links

-

280Z fusible links

What brand is that fuse panel? Looks pretty nice. Many newer cars have similar panels mounted next to the battery like that. Those fuses look much more robust than the typical Maxi-fuse. Ford calls theirs a Mega Fuse. Not sure how many sizes there are. https://www.oemfordpart.com/oem-parts/ford-main-fuse-f87z14526ba

-

280z Throttle Linkage

My memory is that you could take up the slop with your foot on the pedal in the cabin, without moving the throttle blade. It's not clear what you're actually moving in the 1/2 to 3/4. Or why the pedal would come back up that 1/2 to 3/4. Are you taking your foot completely off of the pedal? Can you describe the actual driving effects? What you feel your foot doing and why you think that there is slop? My linkage was adjusted in a way that put the bellcrank over-center at rest. So it was hard to control at low throttle opening. But as far as all of the parts along the way to the actual throttle body, all slop could be removed with slight pressure on the pedal. Riding the throttle pedal is not the same as riding the brake pedal.

-

resurrecting a 1977 280Z

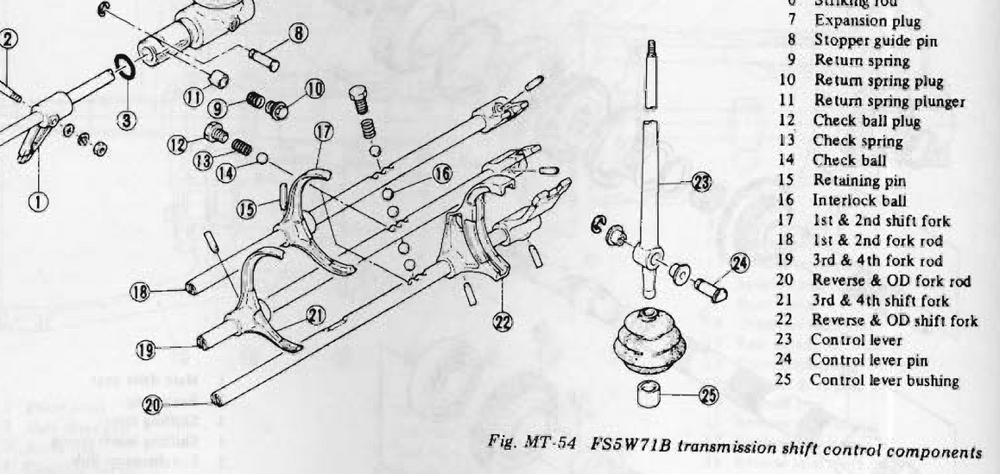

Yes, it's just a simple switch. Somebody had problems fairly recently with a switch that didn't switch. There's a button inside the transmission that rides on the shift rod for reverse and 5th. The rod has a ramped notch cut in to it and the button gets pushed in when the transmission is put in to reverse. It's easy to unscrew and I think it's above the level of the fluid. A meter will tell you if it's good. Or you can just disconnect it, put a meter on it to measure continuity and put the transmission in to reverse. The Nissan draftsmen even drew the notch on to the rod. Part #20.

-

Arrows on the factory U-joint castings - what do they mean?

All of the 280Z and 280ZX halfshafts I had had grease fitting holes, and I collected a bunch. They had the small sealing screws installed in most cases. Maybe Nissan was working their way up to it and the 240Z's didn't get them. Or, maybe it was part of the "budget" sports car program. Left off to save a few cents. Maybe somebody out there has a 280Z or ZX half shaft that they can examine for an arrow. I don't have them anymore.

-

Modern Relay replacements for 280Z Fuel Pump Control Relay and Electronic Fuel Injection Relay?

I was just using the schematics of those relays to show the possibility. The web page has the option of setting your specifications. Just have to put the work in. https://www.boschautoparts.com/g/relays

-

Modern Relay replacements for 280Z Fuel Pump Control Relay and Electronic Fuel Injection Relay?

- Modern Relay replacements for 280Z Fuel Pump Control Relay and Electronic Fuel Injection Relay?

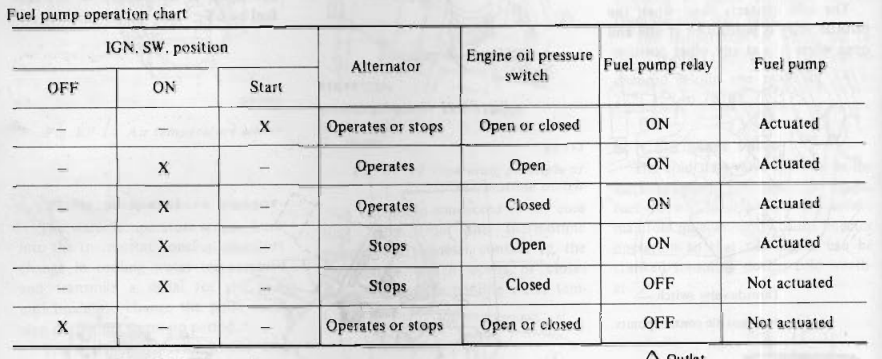

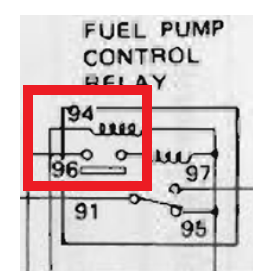

If you break the Fuel Pump Control Relay in to two separate relays I think that you'll find that you can build the circuit easily with two common relays. The EFI relay is a very simple relay with one actuator controlling two circuits. You could also go to the fuel pump control section of the FSM and build your own circuit based on their pump control chart. Nissan just combined them for convenience. https://www.boschautoparts.com/g/relays =controlling- Ads

- 280Z fusible links

- New gas wont start

Did you verify proper contact of the eccentric on the actuating arm? Here's some good stuff. You can test the pump by hand.- 280Z fusible links

It's been pretty well documented that what is shown as a red link is actually a brown link (they're shown in the FSM) and it is also a lower rating (smaller gauge) than the green link (also in the FSM). I never looked too closely at that chart in the past but now see that it has a yellow and a pink link. You won't find those on a Z. Maybe a ZX but not a Z. (Sorry Blue 246, no offense intended). Some of the Z car aftermarket suppliers like thezstore.com have updated their fusible link pages to show it. Don't forget that fusible links are "slow blow" fuses. Most automotive fuses are meant to fail quickly. Good luck.- Z's on BAT and other places collection

Z-Series. A new take on the series designation. https://www.ebay.com/itm/385470127007- New gas wont start

Seems like ZCD might not understand thermal conductivity. Strange. DescriptionNew fuel pump insulator spacer for Datsun 240Z and 260Z cars with mechanical fuel pumps. This spacer has two functions, one is to get the correct spacing for the fuel pump arm to the eccentric on the camshaft and the 2nd purpose is to insulate the fuel pump from heat. One gasket is required on each side of the spacer. Choose from phenolic plastic or billet aluminum.- New gas wont start

He could make his own out of really really thick cereal box cardboard. 😀- New gas wont start

Pretty sure that the spacer is described in that thread I posted. You'll have to work your way through it. If I recall right some pumps didn't have the correct distance from the eccentric or they didn't pump correctly within the range of motion of the arm. Stick it in its spot and see when the arm contacts the eccentric. You'll have to spin the engine a little bit by hand to get on and off the bump. If the arm moves through much of its motion on the base circle that might be a sign that you need the spacer. The spacer might also be part of the heat reduction program. There's a document in the Downloads area about that. carpartsmanual just shows gaskets. Don't know how thick they are. SteveJ has replied. Posting blind!!! https://www.carpartsmanual.com/datsun/Z-1969-1978/engine-240z-260z/fuel-pump-tube/mechanical - Modern Relay replacements for 280Z Fuel Pump Control Relay and Electronic Fuel Injection Relay?

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.