Everything posted by Zed Head

-

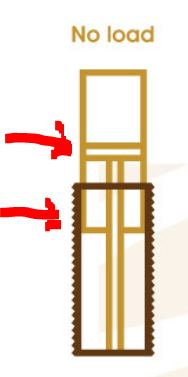

How many threads on coilover to be safe?

Just realized my understanding of the Stance setup was wrong. I think that there shouldn't even be a question of "5 threads". The sleeve is supposed to be screwed all the way in. The threads for ride height adjustment are under the collar, which has plenty of thread left, in the picture. No offense Alby Cage but I think that you might be adjusting the wrong part. Screw the sleeve in and the spring perch up. I might still be wrong. I'd like to see it in action, with no spring, to be sure of full stroke, no binding, etc. The moving part in that strut is the piston inside the shock tube, and the outer portion of the shock tube inside the sleeve. Edit- actually, the best way to adjust it might be so that the shock body bottoms out in the bottom of the strut tube before the internal piston (moving upward in their drawing). Seems like a damper/bumper in the bottom of the tube would be a good idea also. Otherwise it's metal on metal if you hit a big bump.

-

Lowering springs and new struts 280z

The gland nut (strut cap?) is supposed to clamp the shock body tightly in to the strut tube. So it's not so much the nut itself but whether it was working properly. Can't see any of your .HEIC files, whatever they are. Where'd you get the Tokicos? Craigslist, eBay?

-

Tackling 2 leaks, rad and front main

Just feeling a chime in urge. These keys are generally meant for location purposes only, or mainly. The clamping force of the bolt is what stops the movement. 105 foot-lbs, etc. If a person really wanted to be detail-oriented, they'd clean the surfaces that clamp together to ensure high friction and metal to metal contact. The key probably needs to be strong enough to resist the torque transmitted through the bolt head in to the damper. You can sit and imagine where the loads go, if you want to, and figure out what to clean and what to lubricate. Lots of surfaces involved. Lubricate under the bolt head and washer, clean the space between the damper and crankshaft. Choose the right oil for the threads. Say a prayer...

-

How many threads on coilover to be safe?

I see the difference now, with Stance's inverted shock technology. Still, the "sleeve" would be used to adjust shock travel range, and the spring perch to adjust ride height. If you're adjusting the sleeve to get the shock stroke where you want it and running out of threads at the desired ride height, I think that would mean that you need a longer shock. Stance's design is an adjustable spring perch AND an adjustable shock perch. Basically, it's an external shock. You adjust the sleeve to determine where you want the shock piston to start its travel from. You have to consider wheel travel. https://stance-usa.com/about/faq/#toggle-id-1

-

How many threads on coilover to be safe?

Looks like an interesting problem. Not sure of your terminology though, can't really figure out what you mean. "Coilover" is a word with broad meaning, often incorrectly used. It's just short for coil-over-strut. I think the more correct term is MacPherson strut in the front, adn Chapman strut in the back. What people commonly call coil overs, are actually adjustable spring perch struts. Or mixing wrongness, adjustable coilovers. It's not clear how yours work though, because the tube that seems to thread in to the remnant of the original strut tube should only be adjusted to fit the shock insert inside, to create the tight rigid structure necessary to allow the spring and shock to work correctly. The spring perch should be used to adjust ride height. Seems like you're asking about the tube that sets the length of the shock insert portion of the strut. If that's what you're asking about. Maybe take a picture with a finger pointing at the threaded area you're worried about. https://en.wikipedia.org/wiki/MacPherson_strut https://en.wikipedia.org/wiki/Chapman_strut

-

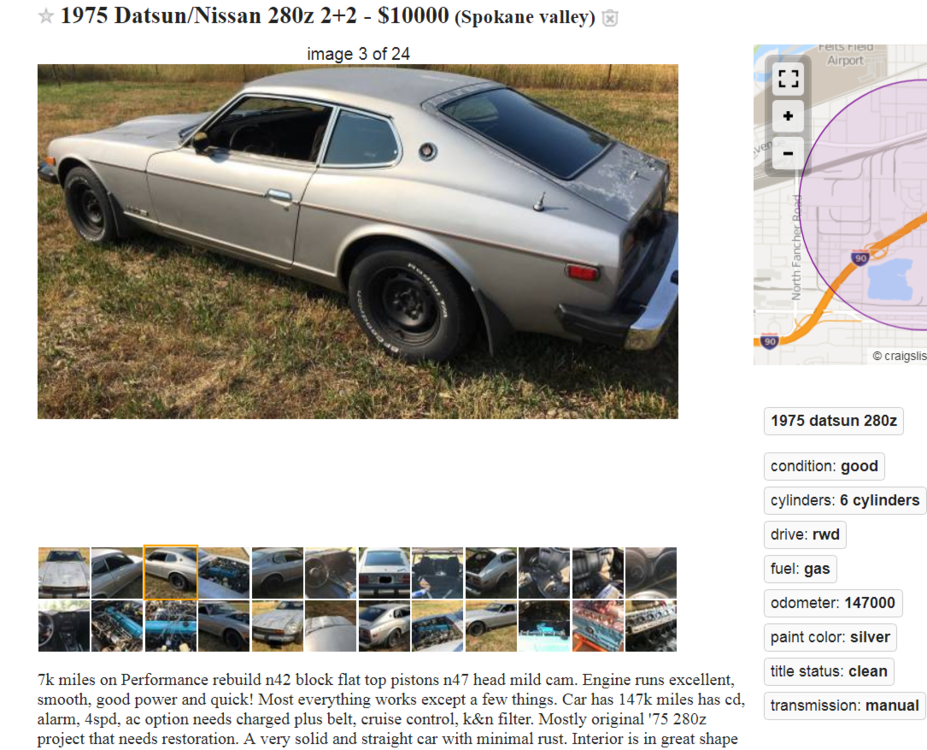

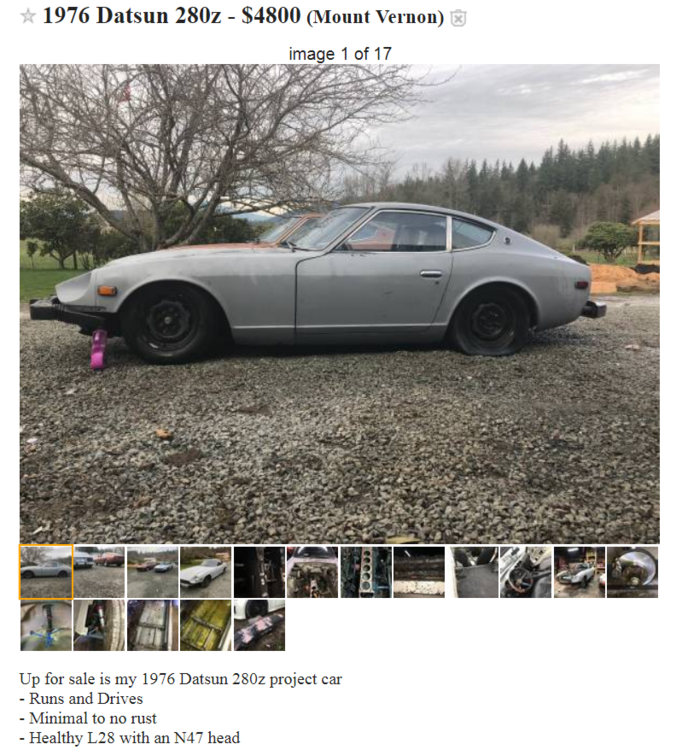

280Z's going up in value!

Sorry if these are members. Just amusing. https://seattle.craigslist.org/see/cto/d/1976-datsun-280z/6476674686.html https://seattle.craigslist.org/est/cto/d/1975-datsun-nissan-280z-22/6496718058.html

-

Rear Hub bearing uneven resistance

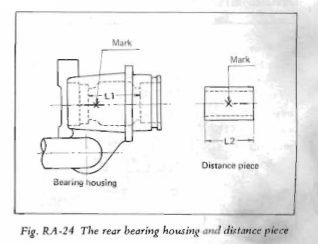

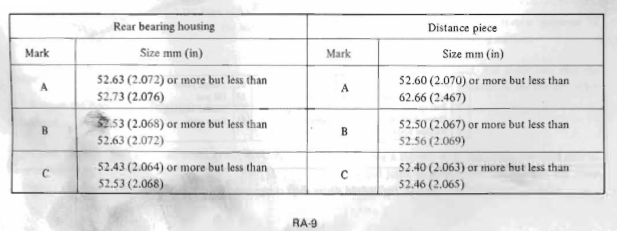

A funky distance piece would do it. Or a strut casting. Or a combination of funk in both. The distance piece is supposed to get the balls centered in the races but it sounds likes yours is a bit short for the casting.

-

Ignition help needed on '78 280z

Are you trying to get everything back to the way it should be or just get the engine started again? You said that you ran it with the fuse box jumpered for a while. You might just reset your thread with a description of what you're trying to achieve, right now, and what the status of things are , like the coil power, and whether you've checked for spark, or tried to start it with fluid. It might be that you actually have an ignition module or distributor problem, and the jumper wire to the fuse box didn't really do anything. It was just a coincidence. A red herring, as they say, or maybe a red herring that swam away. One sequence of troubleshooting that many of use use is - Turn the key to start. Engine turns over. Turn engine over, check for spark. Getting spark, check for fuel. Check for injection. Unsure on fuel or injection, try starting fluid. It should start for a short burst because there is spark. If it starts, then dies, with starting fluid, then troubleshoot injection system. This is a good sequence because those things are in the order that the EFI system would use them. We already know that the engine turns over, and you have power at the coil. Time to do the next step. Spark.

-

Resister tweak for fuel injection

Think I mentioned this in your other thread but you should be able to kill the engine by turning the resistance up. Flood it with fuel. I got the impression over there that you're not seeing any response at all. Maybe you have it plugged in to the wrong circuit. There's a bunch of bullet connectors in the same area, I think. Have you verified a resistance change on the circuit, at the ECU connector? That's what I'd do.

-

Duffy's 1/71 Series 1 240z build

No offense, but once you understand how they work they're not bad when properly installed. Your case sounds like poor installation. It's not the thread insert itself, it's the way it was installed. So, you're right, it was a "half fix" but it's a very common fix. That's why they didn't tell you, probably. You might find thread inserts in some of the other holes that didn't leak. Wouldn't be surprising to find them in the Posi-Quiet calipers either. "Original equipment" just means it started on a Nissan, before they rebuilt it. They didn't cast and machine their own calipers. Notice that they show new pistons, but not new calipers. Better check. Sorry. I'm a bubble buster.

-

Duffy's 1/71 Series 1 240z build

How does it "ruin" it? Might be a clue. But, if you just don't like helicoils, or any repairs at all, it doesn't really matter. Helicoils are just normal repair for any screwed up threaded hole. Screwed up threads are common, that's why "helicoil" is a well-known word of the trades. The other thread insert guys probably hate that. https://www.google.com/search?q=helicoil+definition&spell=1&sa=X&ved=0ahUKEwj2irG9h8nZAhVC3WMKHXvqAPUQBQgkKAA&biw=1496&bih=727

-

Ignition help needed on '78 280z

No need to run a jumper wire to the coil if you already have this. As SteveJ said, just make sure you also have it at Start. Stand your meter up where you can see it or have somebody turn the key for you. Not sure that you're thinking through the things that happen when you turn the key. 12.3 isn't a very well-charged battery. If you have a charger you might top it off.

-

[SOLD] 1973 Datsun 240Z Scarab

The Scarab 240Z's are unusual and of higher value than the common 240Z to many people. Especially if they were built by the guy that designed them (I think that's the guy, right, Brian Morrow?). Here's a link - http://www.zhome.com/rnt/v8.html

-

Ignition help needed on '78 280z

Might be that you actually have two problems. Have you tried starting fluid? If you have power at the coil and still no start, check for spark. If you have no spark consider the igntion module.

-

[SOLD] 1973 Datsun 240Z Scarab

He only has two posts. And I think his avatar is a Porsche. Maybe he was being ironic.

-

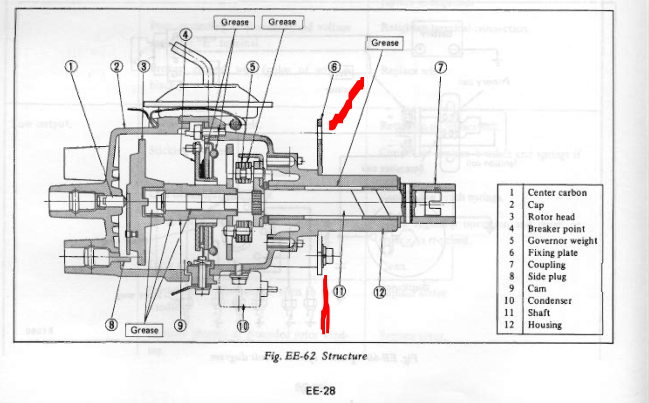

72 240z distributor question

I've read about the drive gear slipping on the shaft. It's not common though. Doesn't look like you're actually measuring and there are other things that could be wrong. Seems like verifying where things are at would be easier than dropping the oil pump and moving the drive gear over a tooth. That's what you'll have to do to get more adjustment. I was just describing how the distributor drive works, above. It's not like a Chevy or Mopar where you just lift the distributor up and re- "stab" it a tooth over. It only fits one way, in one position. Good luck.

-

Ignition help needed on '78 280z

If there is power to the coil and the engine turns over it should start or at least pop a few times, assuming that everything else is right. But, I think that you need to tell us the whole story of the car. You're starting in the middle and there are many things that could be wrong. You could spend weeks on here, giving small details, when there is something simple that will solve the problem. Tell us a story. It's not clear that the engine has ever even run one time.

-

Resister tweak for fuel injection

Stumbling and popping back through the intake manifold at low to mid-range throttle openings.

-

72 240z distributor question

It can't be a "tooth off" unless you removed the oil pump. Or you have a US V8 engine installed. The Datsun distributors use a slot and a tang to tie the distributor shaft to the drive shaft. It can only install one way. Just curious, but what timing are you running now? What's the light say?

-

72 240z distributor question

Patcon makes an excellent point. There is definitely a few degrees of extra on the other adjustment. I dinked around with mine when I was trying to clock my rotor for better centering over the electrodes, when I was trying to run more advance. Funny though, eventually I got tired of trying to squeeze out a few more HP fractions and set everything pretty much back to stock. The FSM shows it with the bolt still in it. You can't see it from the top. I marked the slot that you can see also.

-

Ignition help needed on '78 280z

It doesn't look like you've done much testing besides turning the key and listening and looking. And you said "intermittent" which would mean that sometimes it starts normally. That suggests a bad connection or a stuck relay. Best to get a meter or test light and see where the power is, and where it isn't.

-

72 240z distributor question

There are other ways to get a "tad" more. You could file the slot open a tad more. Nobody can really answer a should question. Should is in the brain of the doer.

-

Ignition help needed on '78 280z

Is it an automatic or a manual transmission? Automatics have an inhibitor relay.

-

Ignition help needed on '78 280z

Can you give a description of what happens when you turn the key? What happens at On, at Start, etc. You haven't supplied much besides the fat that you're bypassing the ignition relay. Could be that that relay is bad. Here's a picture of mine. My car had a wire run all the way to the ignition switch.

-

1976 280Z Restoration Project

I'm not 100% on that. The clip sits in the cap groove and I can't tell how much sticks out. The picture I looked at seemed to have a small edge available. My point was that if there was a force causing the clip to rotate in the groove that the tips might get levered out as it rotated. Like you do when you're removing them. Took a second browse and found another picture that doesn't look 100% either. Maybe a powder coat buildup? I don't know. The clips don't seem to fit the groove super-tightly. Probably not a problem. Makes me feel funny but I'd still run them. Edit - the Nissan parts are just so precisely done that they make everything else look "bad". Color-coded super-precise u-joint clip fitting procedures and all that. Probably why last 200,000 miles.