Everything posted by zKars

-

A Review of Modern Technology Upgrades for Classics

My fingers are tired. I’m going back to wiring up MegaSquirt to my fancy EFI sensors and injectors. More later.

-

A Review of Modern Technology Upgrades for Classics

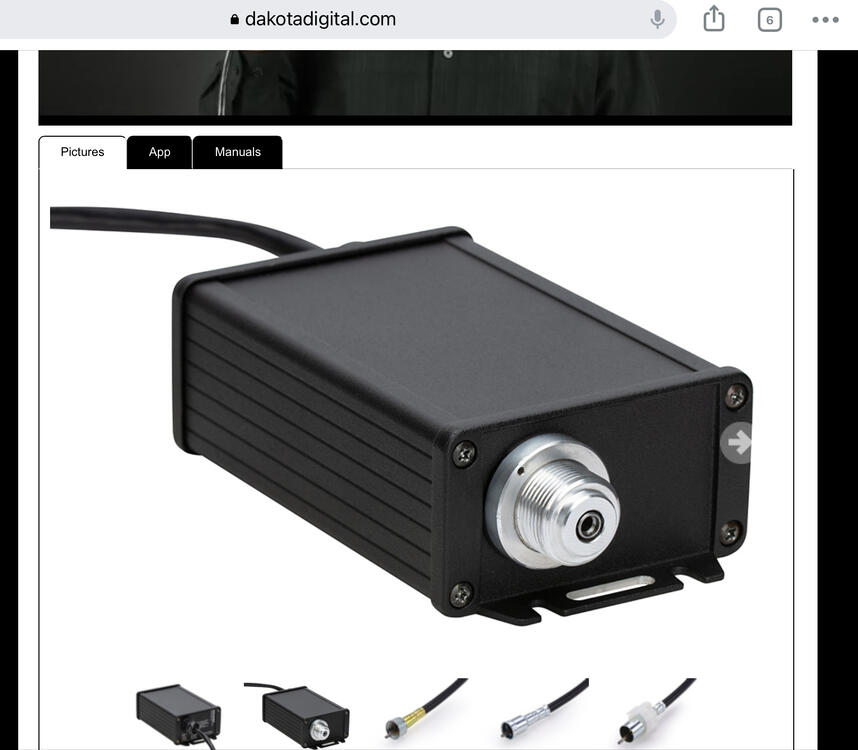

Ok, we have a VSS that gives me a driveshaft rotation frequency, we have a “Way” to use that drive my fancy little ARDUINO board to make a little GM stepper motor point a needle at whatever speedo position I want. Just have to tear up my speedo and mount a stepper motor where that old ancient mechanical speedo and odo gear pile was and I’m flying! Wait just a doggone second….. Odometer….. Sheite….. what do I do about this? Well Mr inventor here thinks I could certainly get my Arduino thingy to add up covered distance and display a ODO number but then I need to include a small LED display thingy in my speedo. Well….. So back to searching for alternatives. Guess what both Speed hut and Dakota digital have invented? A box that converts a speed signal into a motor driven speedo cable. Takes my VSS singal and directly drives my existing and un-modified classic 69 510 speedometer via a 3 foot speedo cable. The ECD-200BT is the Dakota digital version https://www.dakotadigital.com/index.cfm/page/ptype=product/product_id=886/mode=prod/prd886.htm But do they make a Datsun compatible cable? No of course not! But so what. They make a GM cable (duh) that turns out to be 90% identical to a Datsun cable (left one in the picture). The dang threaded cap there is 5/8-16 thread (M16x1.5 Datsun), which JUST ABOUT threads right on, and the cable core is a perfect fit into the datsun speedo (510 and Z same same, don’t worry). So I just removed to GM metal crimped-on housing part and slipped on the nearly identical Datsun end bits. Bit of heat on the metal barrel, out slipped the sheath, same when putting the datsun end back on. Little piece of heat shrink over it if you’re worried about it coming off. So after a quick calibration i need to do when i get the car moving again, which itself is a bit of a modern miracle as the silly box Bluetooths wirelessly to an app on my phone!!! Love this stuff! Just as an aside, the Speedhut box is the same, with one important additional feature. It has a GPS optional input to get speed information from, you don’t need to use the transmission mounted VSS. Even easier. But quite a bit more $$. $320 for the DD box i have and over $500 for the Speedhut one.

-

A Review of Modern Technology Upgrades for Classics

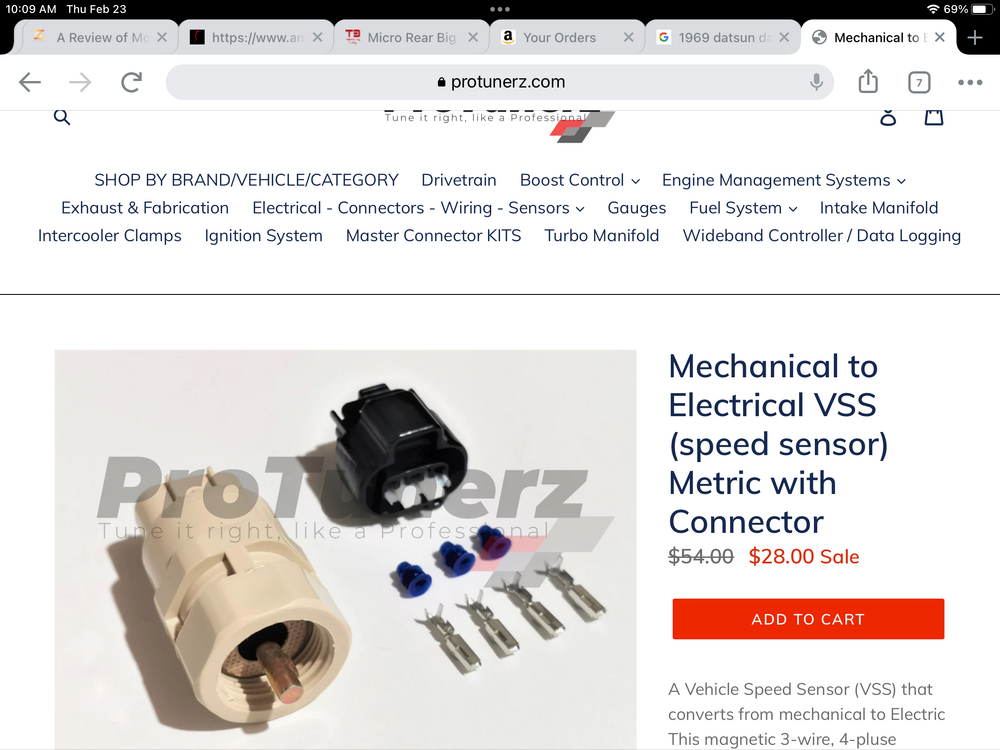

2. Speedo Upgrades The issue here is the ever changing differential gears and tire selections we just can’t help making. The limited choices of transmission pinions gear tooth counts means you might get close, but you will never be very close….. Well, there is a cure. Actually many cures GPS Speedometers. These have been around for a while a. Cheap dash mounted little box that displays speed. Amazon is loaded with options. b. Your cell phone. There are 150 free speedo apps out there. Did I say free? Hardly easy to use in continuous and easy fashion though c. Dedicated aftermarket gauge manufactures. Speedhut, Dakota Digital and others. Seen and owned the Speedhut GPS speedo for my Z, it was great. There are now shops making 3D printed mounting rings for Z’s for all 5 holes. Fabulous. D. Here is where it gets interesting. In my 69 510 (same issue for 68), I do NOT have a round speedometer. It is an old school rectangular sweep speedo. See pic below (not my car, 68 actually but ~same as 69). I love it, I want to keep it, but there are no aftermarket options for this style of electronic speedo. So I start searching for solutions. Step one was DIY stepper motors. Pun intended. Cool stuff. You tell a motor EXACTLY how fast to move, or even better, where to EXACTLY STOP at whatever rotation position you like. How do you think all the OEM’s have been building their instrument clusters for 1000 years? How do you think Speedhut and others build THEIR gauges today? But you say “how can a simple backyard mechanic figure out how to get this electronic gizmo’s to work?” Well it turns out that while we have been toiling in the garage and watching Bachelor in the evenings, the engineering world has been invented a huge range of DIY electronic packages designed at the “young” to get them into robotics and STEM learning. Search ARDUINO or RASPBERRY PIE on youtube. You will spend countless hours saying “OMG” to yourself…… Let me sum this up. After spending $50 bucks in boards and bits, and investing 15 minutes watching a YouTube video, I had a working tiny stepper motor (actually a 2$/100 generic GM instrument stepper motor) driven by a square wave frequency input (more on that in a minute) moving a toothpick speedo needle to anywhere I decreed. FM! Now I have to admit to being a actual engineer (EE) and this stuff ain’t completely new to me so it was “easy” for me to make this leap, but I just didn’t understand the breadth and scope of what is truly EASILY possible now. This leads to the following revelations. Got a fuel gauge that doesn’t match your new fuel sender in your new tank? No problem. Don’t want to spend the current insane $500 USD and up to find a used and rare stock tach for your 510? Make you’re own…… Now I’ll show the next link in this chain, The VSS. Vehicle speed sensor. To drive all this fancy stuff, you need to have a digital signal that tells you have fast your driveshaft is spinning (needed for cruise control too!) Well there is this cool little device, available from ProTunerZ. I first tound it years ago through a Toyota 4x4 supplier. https://www.marlincrawler.com/transfer-case/parts-upgrade/misc-hardware/vehicle-speed-sensor-mci Turns out the threads on the toyota tranny’s speedo cable pinion is the same as Datsun. Screw this little gem on YOUR speedo pinion add 12v and a 1K resistor, and you get this lovely perfect 12v 50% duty cycle square wave output at a frequency 4 times the pinion rotation rate. For $28 buck.s Yeah. BTW, the gear ratio of YOUR speedo pinion is computed by dividing 6 by the # of teeth on whatever pinion you have. 6/16 (yellow 16 tooth I think) is .375. So at 3000 RPM driveshaft speed your pinion is going 0.375 times slower. Use your tire circumference and diff gear ratio to compute Rotations per mile.

-

A Review of Modern Technology Upgrades for Classics

1. EFI Conversion I am not going to tell you every detail about how to do this, just to make the point that while it can be daunting, it is SO WORTH IT. I did an EFI conversion on my “other” 69 510 back in 2018 and have never looked back. The increase in reliability, drivability, and maybe mostly the ability to be informed about the state of the engine, and the ease of monitoring any input or output has made it a pleasure to drive. I have done literally NOTHING other than routine maintenance in 5 years…. Hop in, drive it. Park it for the winter. Hop in April drive it till it snows. Repeat. It’s cool vintage looking. I used the Jenvey Heritage Throttle bodies that look like dual webber carbs. I get the classic look and appeal but it runs like a modern car. On this one I’m doing more or less what Datsun did with the 280z EFI, just the 4 cylinder version of that. Bit of rare kit, but that makes it fun. “L18E” is the thing to look up if you want to find out more. I’m only using the intake manifold. The high tech part of this that I will identify and name is summed up in one acronym, CANBUS. If you do an EFI conversion, get a system that has CANBUS at it’s heart. It will be give you control and monitoring in a hundred ways. I used HALTECH on the first 510, I’m using MegaSquirt 3 Pro/Evo on this one. There are “easier” options, like using a 4 barrel manifold and bolting on Holley’s EFI system with a 4 barrel EFI carb looking thing. But make no mistake, this is not for the faint of heart no matter what you do. Perhaps the hardest part is the need for an “outside”, ie a tuner to make it all run right after you build the hardware.

-

A Review of Modern Technology Upgrades for Classics

A lot has happened since November’s first kiss of white wonder that drove me into the garage, but what I want to share here is what I think are important “opportunities” for classic restorers who just need to have some modern features in their cars. A ton of stuff is out there, the more I find the more I am amazed. I will not be discussing stereo’s or A/C, enough has already been said on this topic. No I will discussing really modern and high tech stuff. First a quick summary of the these groups of technology that I’m tinkering with and want to share. 1. EFI convesion. 2. Speedometer upgrades or perhaps “Instrumentation” upgrades is a better way of 3. Cruise control 4. Power locks 5. Seats. Let me be clear. I am deliberately and consciously doing my best to retain classic look and feel in this restoration, everything I have found and will discuss here be related to how i used these modern toys to retain that.

-

A Review of Modern Technology Upgrades for Classics

Greeting from freezing western Canada in February. When things get cold and you can’t drive, I spend the winters working on garage projects and this year is no different. Last winter I did a restoration on the latest 69 510 sedan I found, trying my dang-dest to do a as close to stock restoration as I could stand for a change. This one was kinda special, one owner, low miles, low rust and great backstory. I won’t share any of that story in this thread. Just suffice to say I had a hankering to drive a stock 510. Got it done and started driving it last fall, spent all of 2 months putting some miles on it and loving most of it. Gentle ride, decently quiet exhaust. Snappy little L!8 SSS motor. Ok, THAT’s not stock but it’s OEM un-modified SSS L18. So it was stock in SOMETHING, okay? Fine….. Then the first blast-O-winter hit Alberta in November and in the garage it went cause it had two problems. Noisy transmission in 5th and REALLY BAD seats. You think stock Z seats aren’t “perfectly comfortable and supportive”? Well 510 seats are AWFUL for long trips and or any sort of performance driving. Yes I had a very low mileage set that I restored to lovely appearance and function, but…… And so it began. Will I be able to restrain myself and limit the “upgrades” to just the barely acceptable minimums or will it get out of hand? Do I really have to tell you what happened?

-

Steering column lower u-joint replacement part

Haven’t done this for a while (done 10+ before hand), but sourcing ATV700 part number u-joints never resulted in any issues during reassembly. If you have to do a little “clearancing” with whatever parts are now available, well it never hurts. Sounds like what I always have to do with GM alternator replacements. Some part of the case or mounting bracket has to be “relieved” to make it swing in close enough to get the belt on. Just what you have to do. What I do remember is the last time I ordered more from the u-joint store I think, they were having supply chain issues and couldn’t supply any. Will have to check again.

-

What is this part?

It is a voltage regulator. The plug style was used 75-78 and possibly late 260. Early 260 had a one time only round solid black plug, all 240’s had a 6 pin rectangular flat pinned plug. The parts fiche gives you an idea of how many unique ones were made and start and stop dates. All do exactly the same thing. You could switch plugs and use a reg from any year technically. At some point in the late 280’s the alternators went to the internally regulated style (designations starting with LR rather than the earlier LT) and the external regulator nonsense was put to rest. Many replacement regulators you buy today have transistor based relays rather than mechanical ones for enhanced reliability if you are stuck with an LT alternator. Common practice now is to use later GM or later Nissan alternators with higher output anyway. Tons of threads here and else suggest what you might use.

-

Engine Shipping Crate Designs

I did the modern thing and googled “Engine Shipping Crate”. Quite enlightening what’s out there. Plastic two piece clam shell boxes are very popular. Shippers also love pallets. Few pieces of wood under strategic places to support it upright, basic tie down ratchet straps to lock down to the pallet slats. No need to “enclose it in a box”

-

Restoring interior vents

There are aftermarket replacements for the 240z eyeballs vents, but not the 280z ones. Going to have to find a better set of used ones or someplace that does plastic chroming.

-

low oil pressure

Just to put it out there plainly, the block threads are 1/8 BSPT. The adapter needed is the one SteveJ linked to, BSPT male into the block, 1/8 NPT female to thread in common gauge fittings.

-

Thermostatic Valve needed...any idea where to get one?

Seven years. OMG. Yes I still have some.

-

Vintage Connections Prices Increasing

I’ll do the same. Thanks for the reminder.

-

Brakes rubbing after remounting wheels

You lowered the car too much. Does it rub when you turn? Or turn and going over bumps? Stop, turn the wheels full left and get out and look what’s close to what.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

So: If I may be so bold as to offer a final summation: Made of wood? No. Made with wood? Yes Looks like wood? Yes to most, no for some, but it is one of the basic design design objectives of this damn thing, so Yes is reasonably correct. Which wood? Who cares. As long as it makes most drivers think “wood”. Feels like wood? Doesn’t matter. Original question is “wood yes or no”. See above. Made of plastic? No Made with plastic? Yes Feels like plastic? See above.

-

Rebuilding R160 and/R180. Tip for bearing replacement.

On to that really nasty race that on the inside of the pinion shaft. Getting it out is easy, but getting it lined up and beaten back into place from the nose is a real test of wills. It’s down there about 10 inches…..

-

Rebuilding R160 and/R180. Tip for bearing replacement.

Clamped it in the vice upright, got the MAP gas torch out (propane would be just fine) and warmed up the outer circumference for about 90 seconds. The race just popped out with minimal prying with a flat blade behind it. 5 minutes, both sides done. Bamn!

-

Rebuilding R160 and/R180. Tip for bearing replacement.

The other day I was tearing into a Subie R160 CLSD that had sustained some rust damage and thought I’d better replace the bearings. When I got to the races in the outer side covers I began my usual anxiety cycle where I think of 11 ways to get them out, but all are risky and start doubting if I can figure it out. The dang covers are aluminum and the races are stell, so there is no bangin’ or rippin’ allowed. There is no place to just punch them out, the thick edge you have to apply force to is well shrouded. An internal bearing puller might work but you have to rig up a plate to bolt the hole thing to. Bah After about an hour of going back and forth with ideas, each one more extreme and time consuming than the last, BANG the right way leaped into my heat. Heat. Aluminum expands like crazy compared to steel.

-

air filter source

Glad you found one. Getting a bit tricky to source. There is a K&N Filter for the 240 as well. E2910 I believe. I’m no great fan of the K&N filter, but this particular filter body is rubber and a tad thicker than stock, so if your housing is lacking the thin stock rubber strips that seal against usual OEM steel filter, these would be ideal.

-

280z Interior Plastic Repair and SEM coat

Don’t interchange the vinyl and plastic preps. They are different. You’re welcome

-

280z Interior Plastic Repair and SEM coat

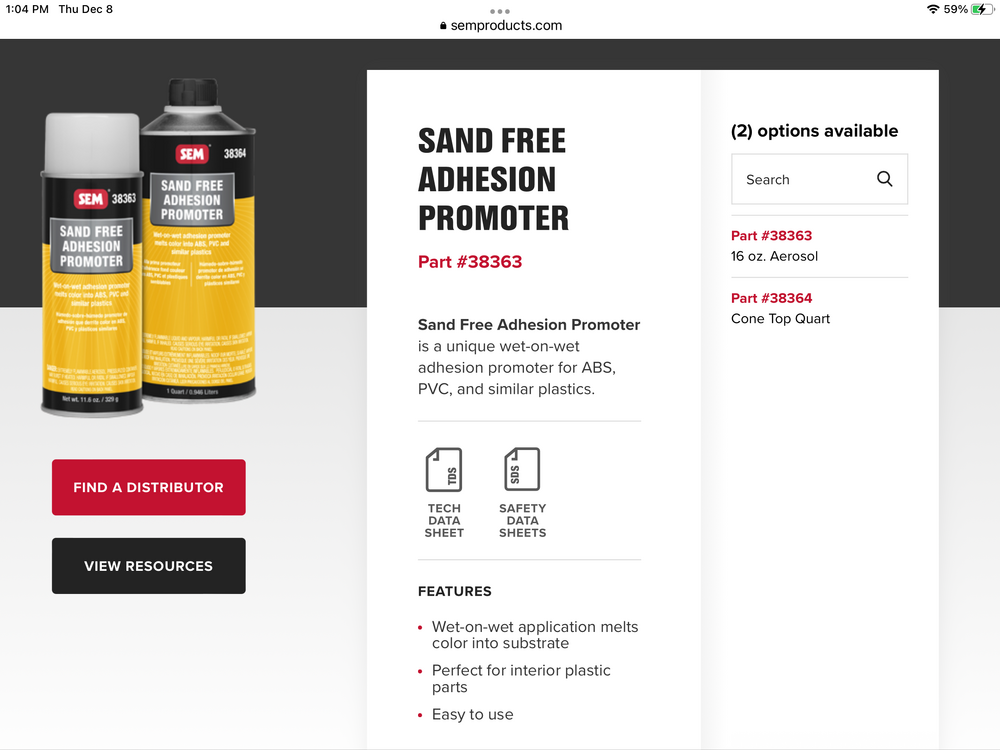

Done plenty of all of this. SEM Plastic Prep (not vinyl prep) works wonderfully, It’s primary job is to clean and degrease to remove traces of everything un-desirable. Then use an adhesion promoter like SEM 39863 JUST before spraying the top coat. This softens the plastic and let the top coat stick. Franky anything that will thoroughly degrease the plastic and clean it without leaving any residue will work. I’ve recently been using generic body shop degreaser to clean, even Spray 9, anything powerful and degreaser-y. Then Adhesion promoter, THEN top coat. The Sand Free product sounds like a newer development for coloring plastics. I haven’t used it, but the description sounds interesting. PLASTICS only. Vinyl and leather dying is different. The Vinyl preps typically clean and degrease and do the adhesion promotion all at once. Filthy vinyl, use spray 9 and a scrub brush and water rinse, THEN vinyl prep just before top coat. Cannot stress enough the need to clean the plastic or vinyl extremely well. None of the top coats stick to 30 years of sweat, body oil and Armor-All worth a damn. Big surprise. I’ve even used Scotch brite pads to scrub to get whatever off da plastic first. Hope that helps

-

what happens when safety comes last...

My entire head, face and upper body were subjected to a huge flood of ATF that came out of at least two plug holes on an engine that had been literally FILLED with ATF as I attempted to crank it over. It was as if the engine had been filled to overflowing with ATF with 2-3 gallons worth to preserve it I suppose. The engine did eventually start, and I discovered that of course the exhaust was also filled with ATF and the initial start up caused a huge soggy mess of mouse nest and ATF to be ejected out the exhaust and directly onto the side of my Ford F150 that was parked across the open garage door. That Z smokes for weeks afterwards as the ATF eventually burned off. I have a picture somewhere

-

Taking Apart 240Z Spring Loaded Seat Hinge

Well I’ll be horn swaggled….. All the invented drama for nothin’ Been watching too much reality TV apparently. When seat back is all the way forward, no tension. Nothing happens until you start pushing it backward. Duh…. I’m going to go take some apart just to laugh at them….

-

Taking Apart 240Z Spring Loaded Seat Hinge

Right! The cotter pin! With that it will be easy. Bolt it to the bench, put an extension on the arm of some kind, pull the cotter and pin, and un-wind it. Easy peasy. Make sure your life insurance in paid up first…..

-

Taking Apart 240Z Spring Loaded Seat Hinge

Clearly these hinges were never intended to be disassembled, all fittings are permanent rivets and spot welds. If I had to disassemble it, I would bolt the seat bottom section to a solid surface (work bench) and bolt a long strong extension to the seat back bracket (like two feet) to give me leverage on that spring when I did grind off the welds or pin heads so I’d have a prayer of holding it back. Then I could hold that long lever and slowly unwind it. Do the reverse to assemble. I would also try to convince someone I don’t like to do it for me…. Or just sand blast what is visible and paint it grease it and be happy……

Subscriber

Subscriber