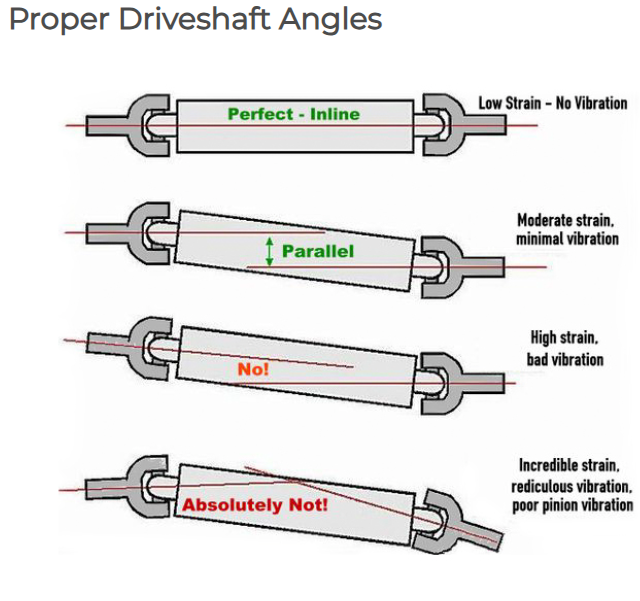

I had the same thought about needing some angle being necessary to work the needle bearings. Side note about the "AI Overview". It is basically a boiled down compilation of everything available on the internet. Including all of the garbage and nonsense. The tech marketers want us to start believing what the AI algorithms produce. But, really, it should all be ignored and only verified professional sources should be considered. At this point in time, "AI" is good for entertainment purposes only. If you really study the statement below you'll see that it actually says very little, and some of it makes little sense. Like "allow the shaft to change angle". Empty words, really. No offense intended. It's just another of those things to be worried about. The word intelligence does not guarantee intelligence.

Subscriber

Subscriber 1Points2,733Posts

1Points2,733Posts Subscriber

Subscriber 1Points1,281Posts

1Points1,281Posts

.thumb.jpg.f5b4b3de6b44cc690d44f1de497a4955.jpg)