Recently, I sent off a small box of hardware for plating. Unknown to me, the place I sent the parts to had gone out of business, and my box got hung up in the UPS/USPS system for quite a while. But, I was successful in getting the box of parts back finally, after many weeks. I found another plater, and sent the parts off again. He got them done literally over a weekend and got them back to me already.

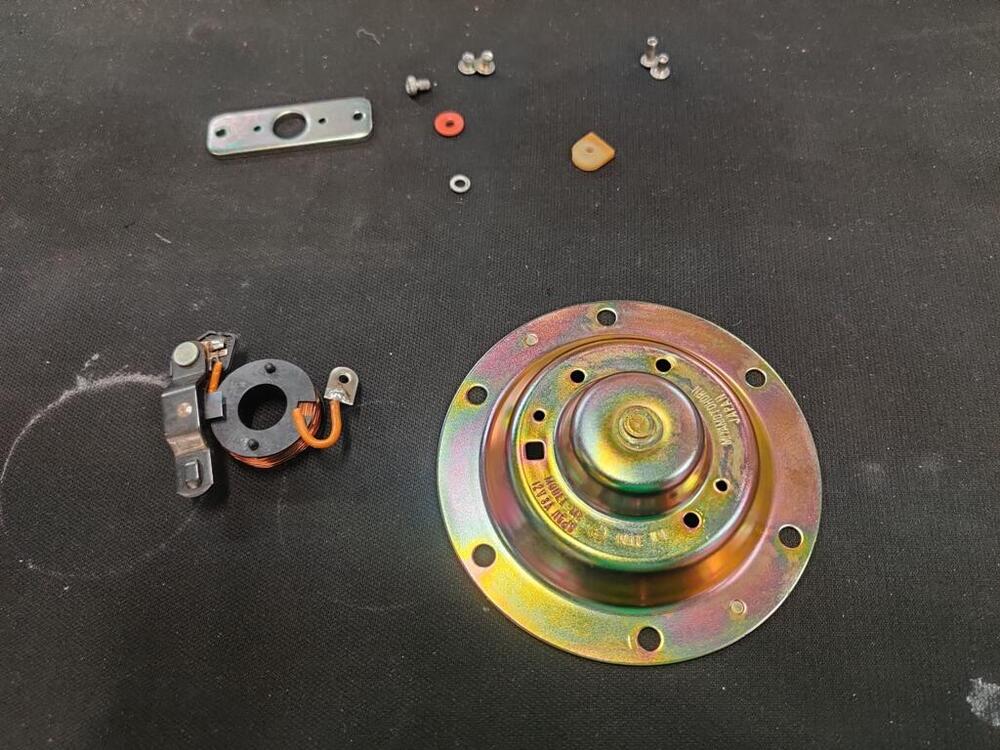

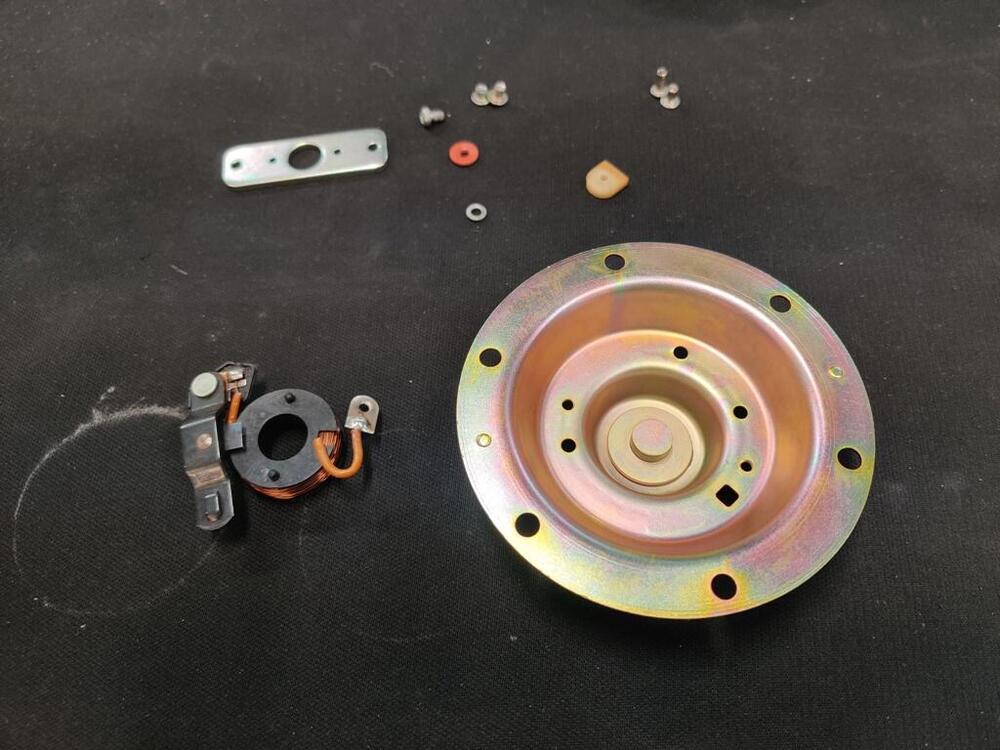

For the horns, the first plater I sent them to wouldn't do them. So, this time, I drilled out the rivets holding the electrical parts to the back plate and sent the back plates off for re-plating. I had to order "semi-tubular" rivets and "rivet curling punches" to set the new rivets. Today I experimented a bit with those.

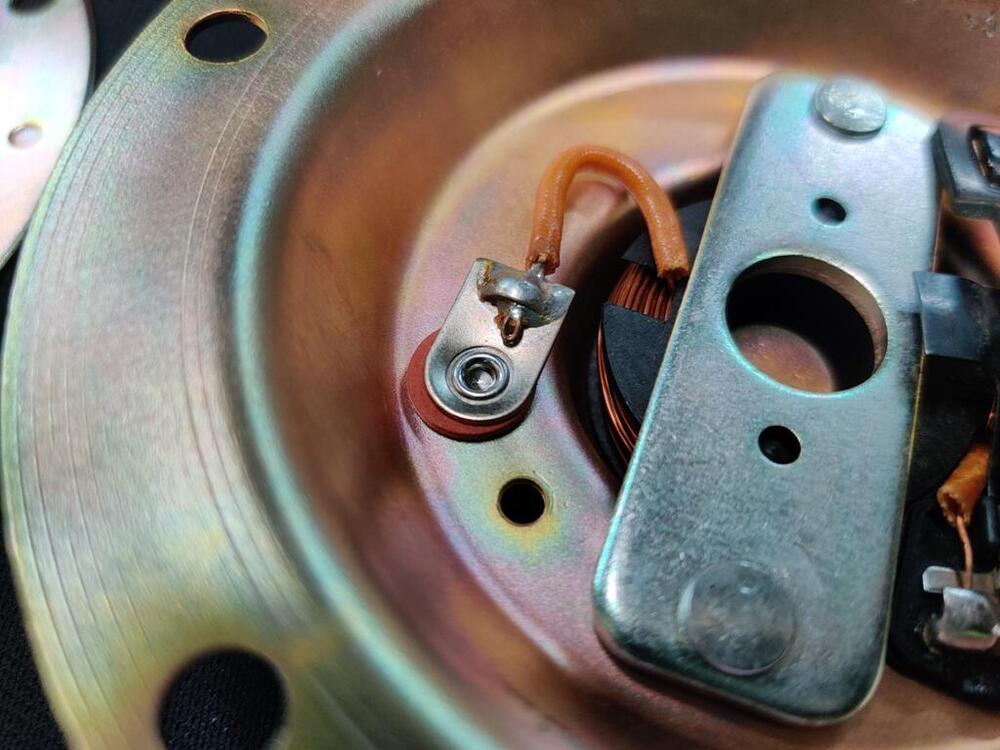

The rivets for the "bridge bar" need a bit more work, I think:

The rivet for the spade connector looks perfect:

Didn't have much time to work on them tonight, but should be able finish them up this weekend.

Subscriber

Subscriber 5Points1,282Posts

5Points1,282Posts Subscriber

Subscriber 3Points11,142Posts

3Points11,142Posts