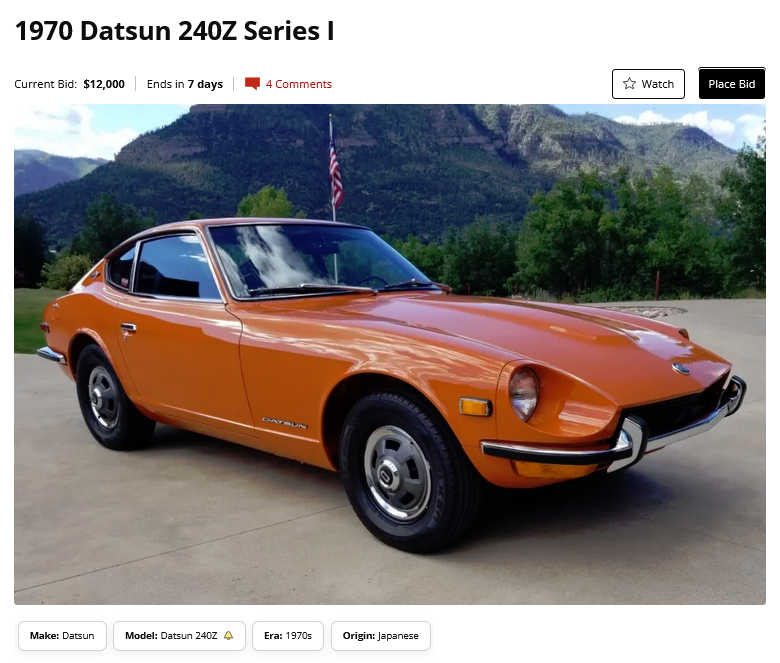

So to continue with my version using the '91-02 Ford Escort heater core (thanks Capt. Obvious!) I ordered the heater valve mentioned by another -4 Seasons 74627 - but it didn't arrive until late this evening, so I dismantled the original & had a go at fixing it following the other thread

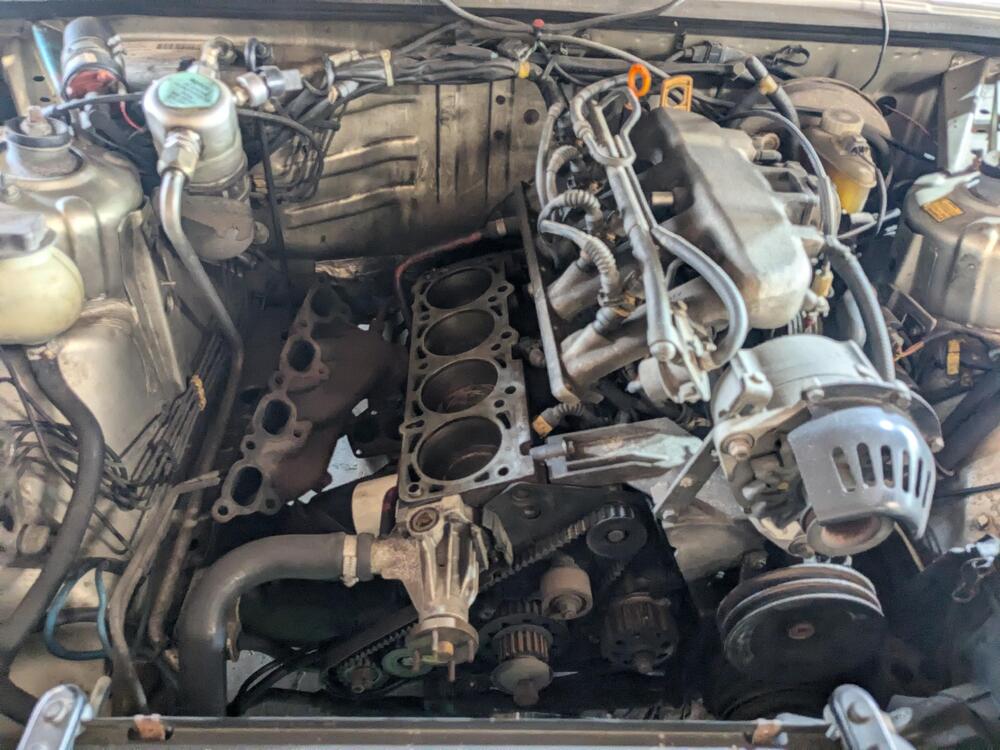

Think it's pretty clear why the heat never shut off - large chunk of silicone wedged in there

I forgot to take pics of the re-assembly, I used a Viton o-ring in place of the square cut outer seal, I left the inner one alone. Left it set on an angle filled with fluid to check for leaks.

This is what my phone screen looks like (actually worse now, it's all dark) - so my pics are hit & miss

I flipped the I/O for the heater hoses - the bulkhead upper is now the return & the outer/lower is the feed. I did it this way so that the feed is not too short, and the return is a straighter run. and so the inside feed is a plain elbow 90º. Determining hose lengths (cut from Volvo 700 formed hoses) here. SS tubing is 20.5".

dogleg for the other end, test fit alignment of pipe & hoses

Hoses cut & clamped (head fitting was removed, de-rusted, sealed & reinstalled, slight offset change -more vertical

Far end adjusted & clamped

With that end out of the way, I returned to the heater valve & core. Eyeballed holes for core pipes, based on the core being centered. Added closed cell foam on the sides to make it snug, and to the front to keep it pushed all the way in & cover up the old pipe holes.

Was playing with hose routing - this way was to allow the 74627 straight pipe valve to sit above the feed pipe

along these lines

I'll revert to this layout if I need to switch to the 74627 valve

When it became clear that the 74627 wasn't coming , I switched gears & worked on fitting the original repaired valve -

Heater valve fitted using the upper existing mount screw, new hole drilled in plate. Cut a notch in the valve mount bracket to clear the lower screw. Checked that flap can open.

Feed hose clamped. Cable attached & function tested.

Test fitting (formed, Volvo) hoses to & from heater valve

Added oetiker clamps after this. Since I wasn't able to flare the end of the core tubing, I prefer them as the clamping is typically more uniform than a worm clamp of any type.