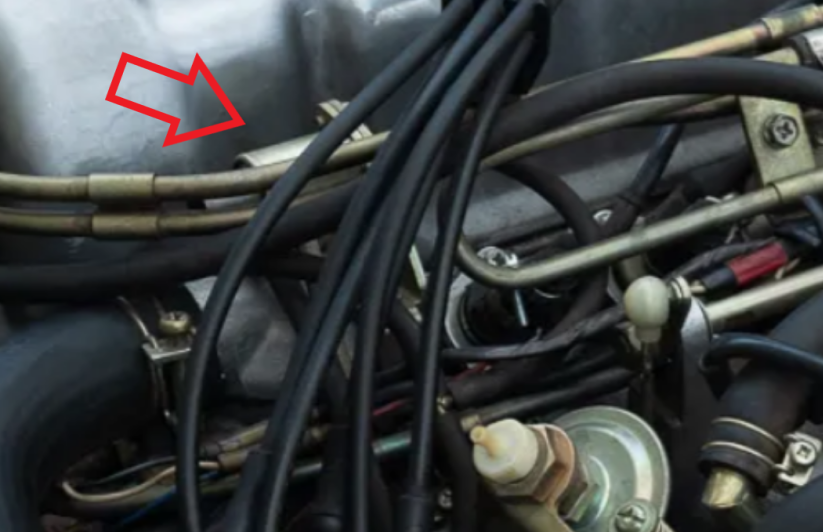

I found another wiring issue - I noticed that the driver's seat wasn't working one day, so I swapped out the fuse - that lasted for several days, seat was working fine, then I came back to it about a week later & it was blown again. I swapped out the fuse, and operated the seat reaching over from the passenger side, worked just fine every time. A side issue of my own creation here is that I wired the switched feed to the power seats from the same fuse that governs the Volvo constant idle system - so on at least one occasion that fuse blew instead of the seat fuse, which meant no idle control & stalling condition on decel. Of course THAT happened when the wife was in the car, so now she feels even less safe driving around in the car. I have to rewire the feed so it has no impact on any other circuits.

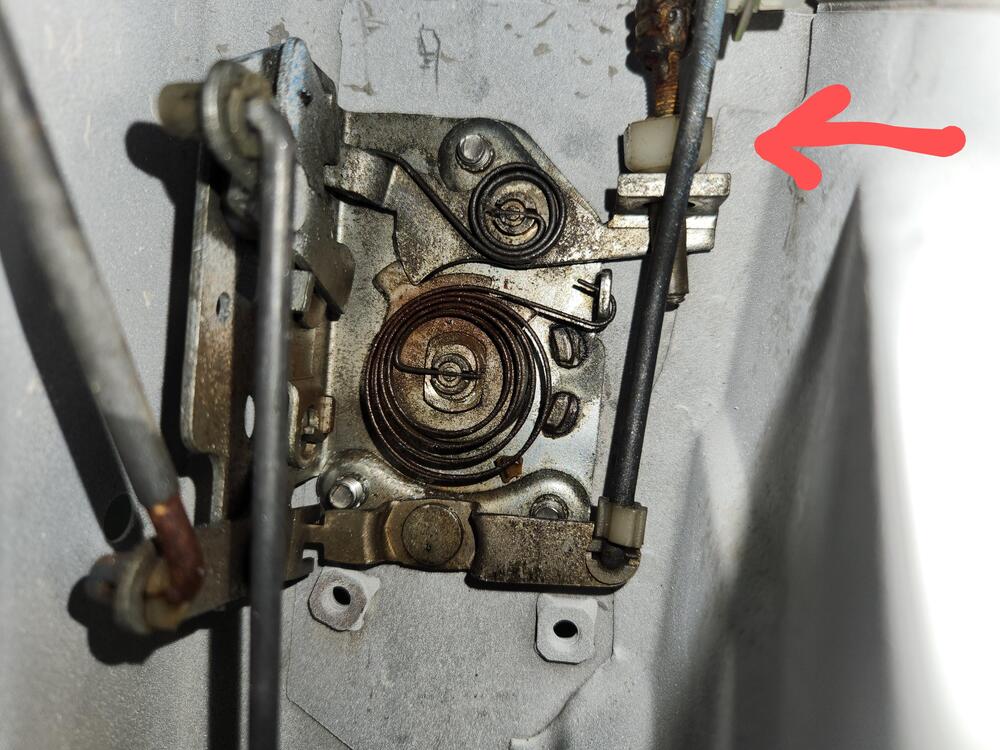

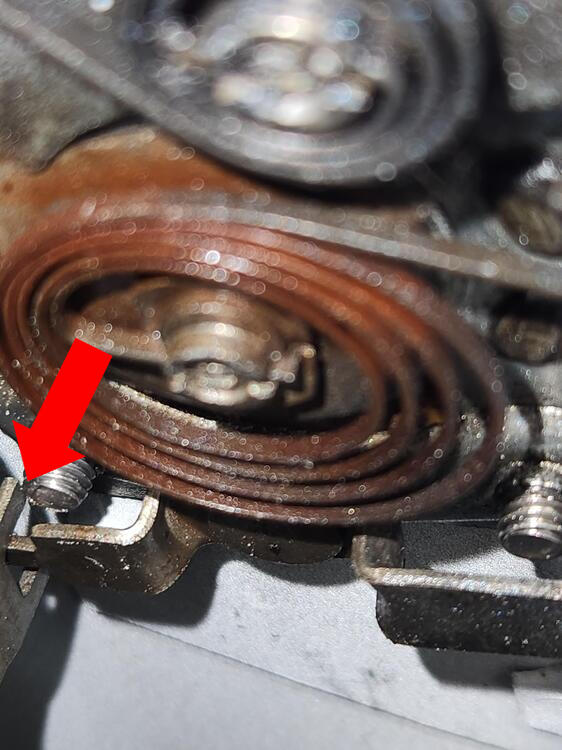

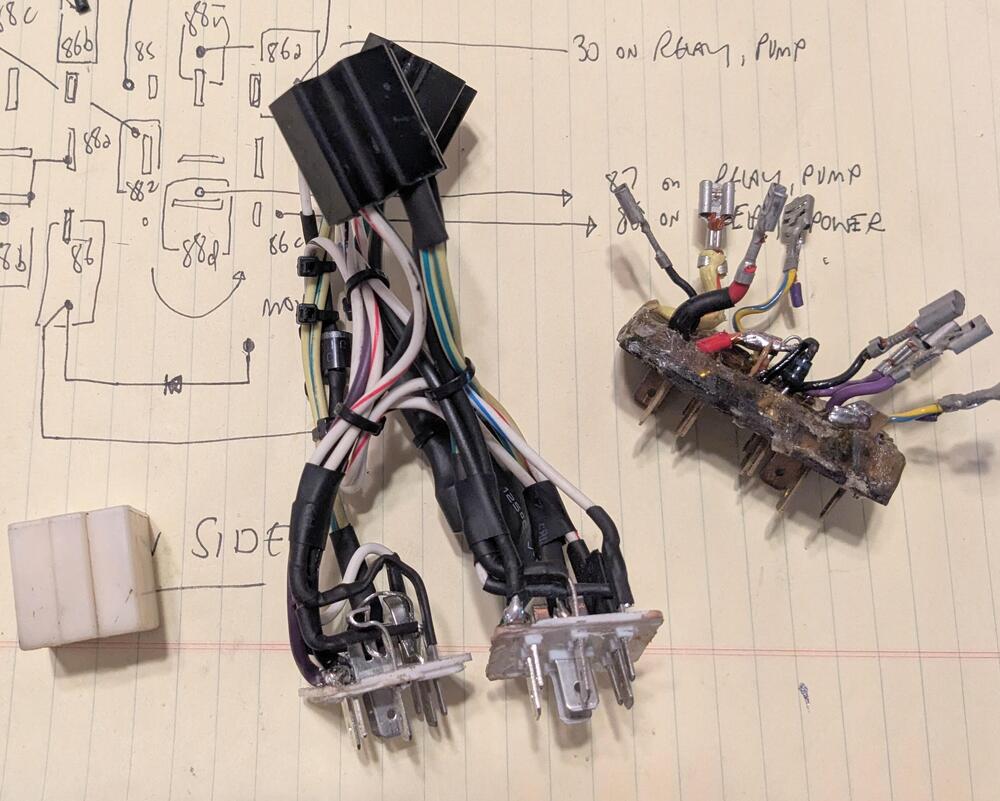

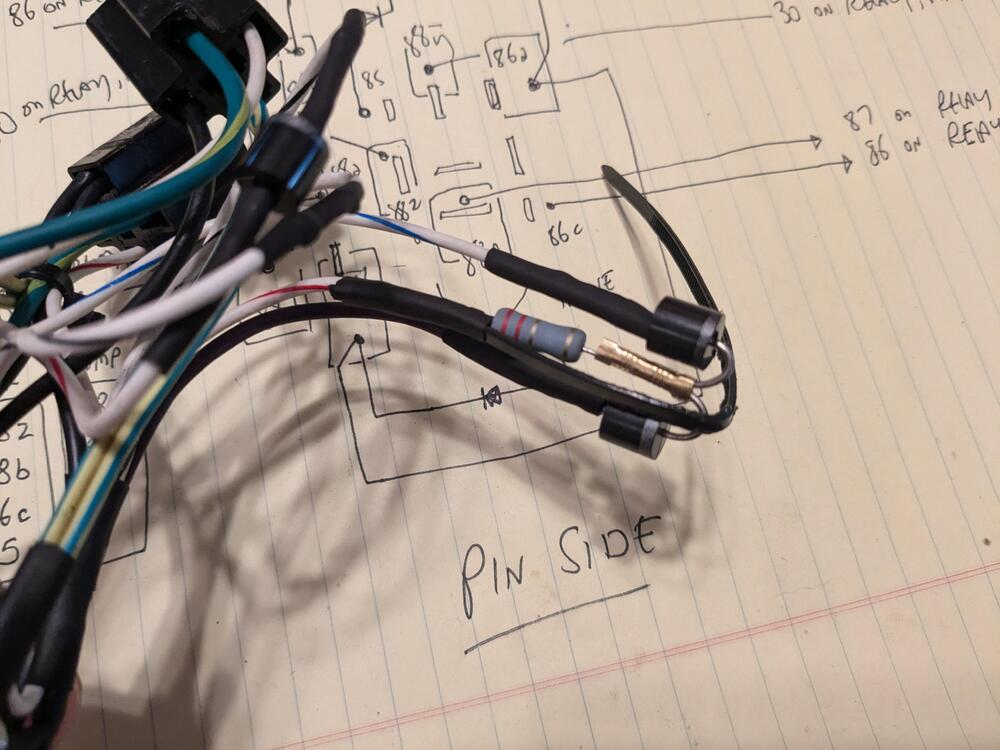

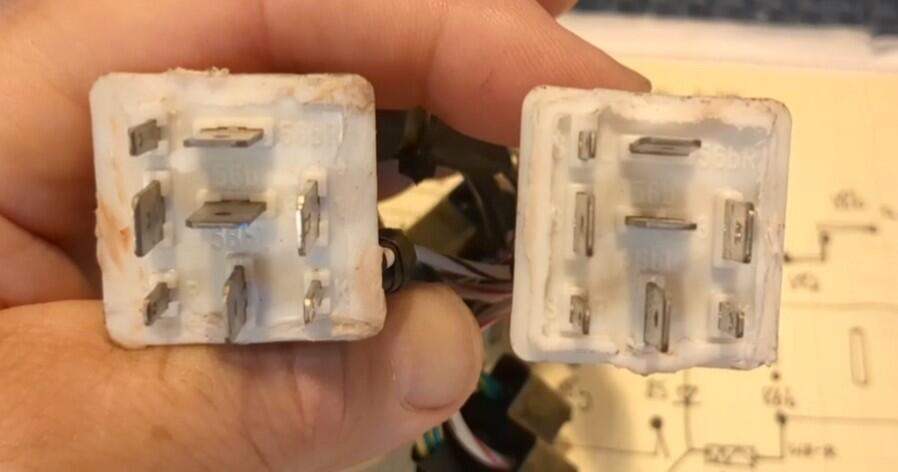

Drove the car again & the fuse blew. So, my weight on the seat was a contributing factor - I thought I had been careful to route the wiring where there would be no contact. I found this (pic below) when I pulled the seat switch. I had already purchased a new one, since I had no idea what spect of the switch was shorting the fuse, so now I have a spare (sleeved the exposed wire).

EDIT- Looking through my seat install pics - I'd say the upturned channel lip is the problem.

Subscriber

Subscriber 4Points11,142Posts

4Points11,142Posts