I have been rebuilding my differential for the last couple of evenings. It is a "K" R180 from the front of a Nissan 4X4 truck. From running it in my 240z, I know it was in good condition before disassembly. And, when I took it apart, I checked backlash and it was within spec. So, I don't believe it ever had been apart before.

I purchased a Quaife LSD for it. I also purchased all new bearings and seals.

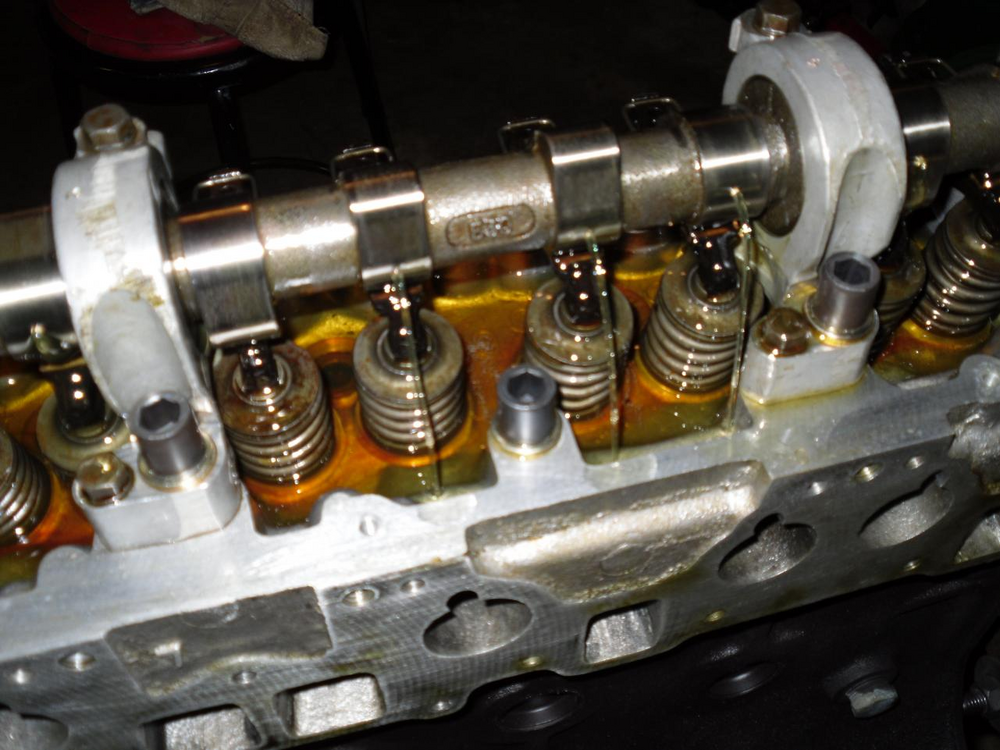

For the differential case and the drive pinion shaft, I was very careful to install races and the tapered bearings, fully seating them in their correct positions. I also was sure to use the spacers and shims that were removed back in their original locations.

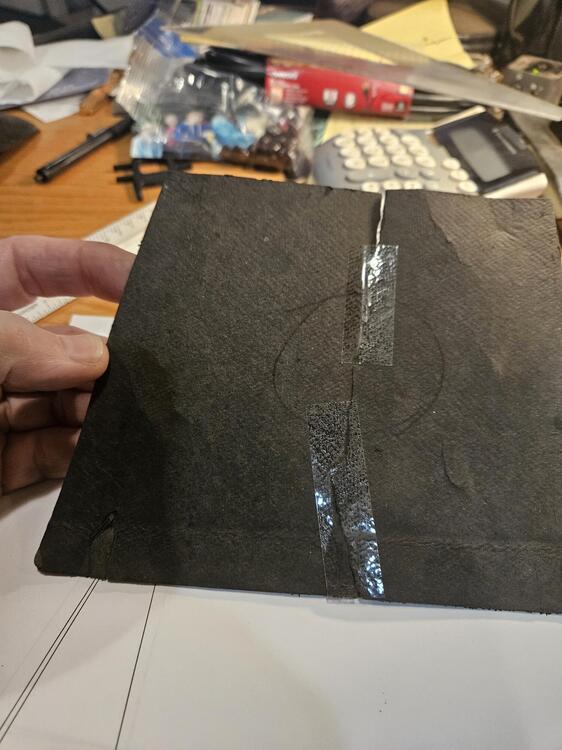

Using old bearing as an installation tool for the front pinion bearing.

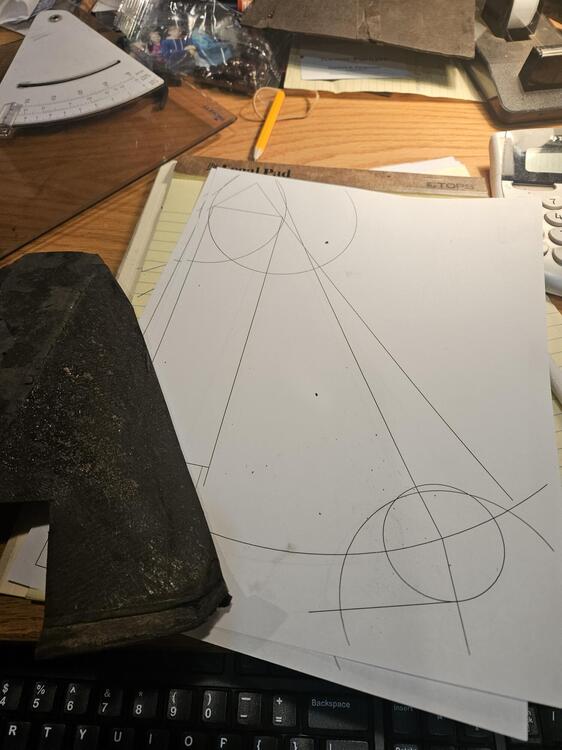

Using a homemade tool to hold the pinion from turning while setting the torque to 135 ft-lbs (factory manual specifies 122.9 -144.6 ft-lbs_

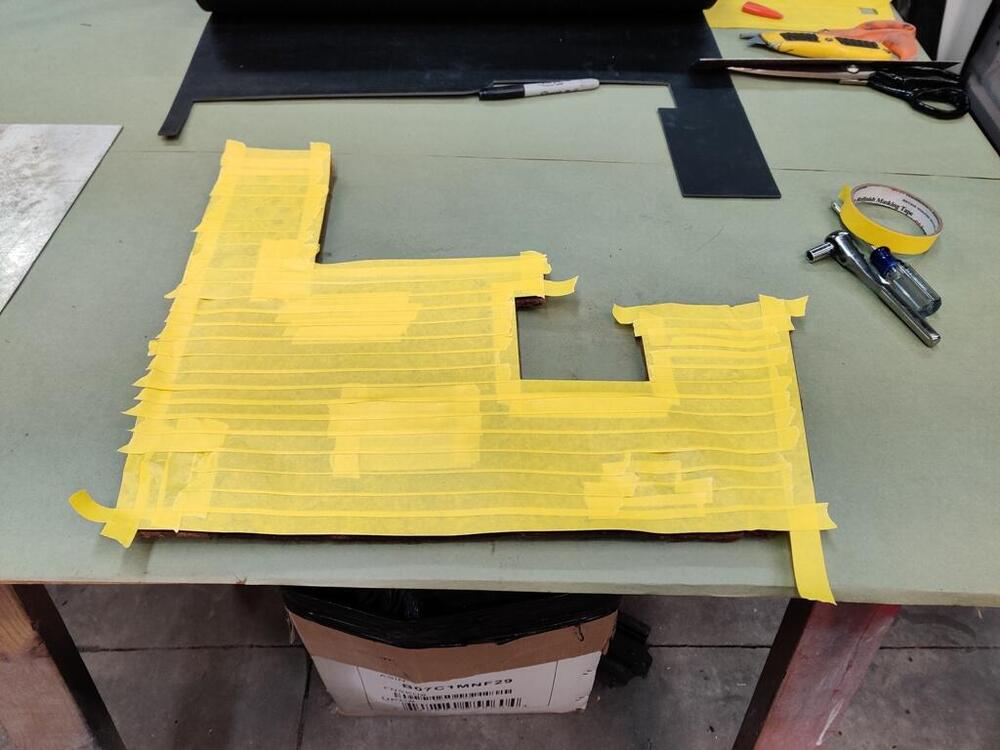

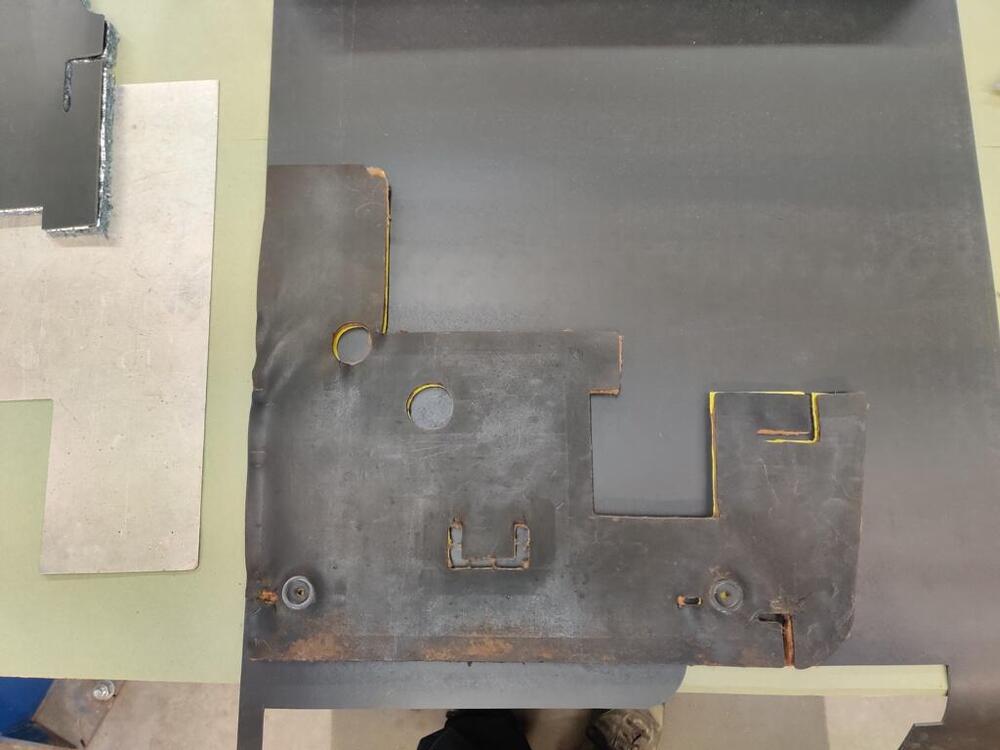

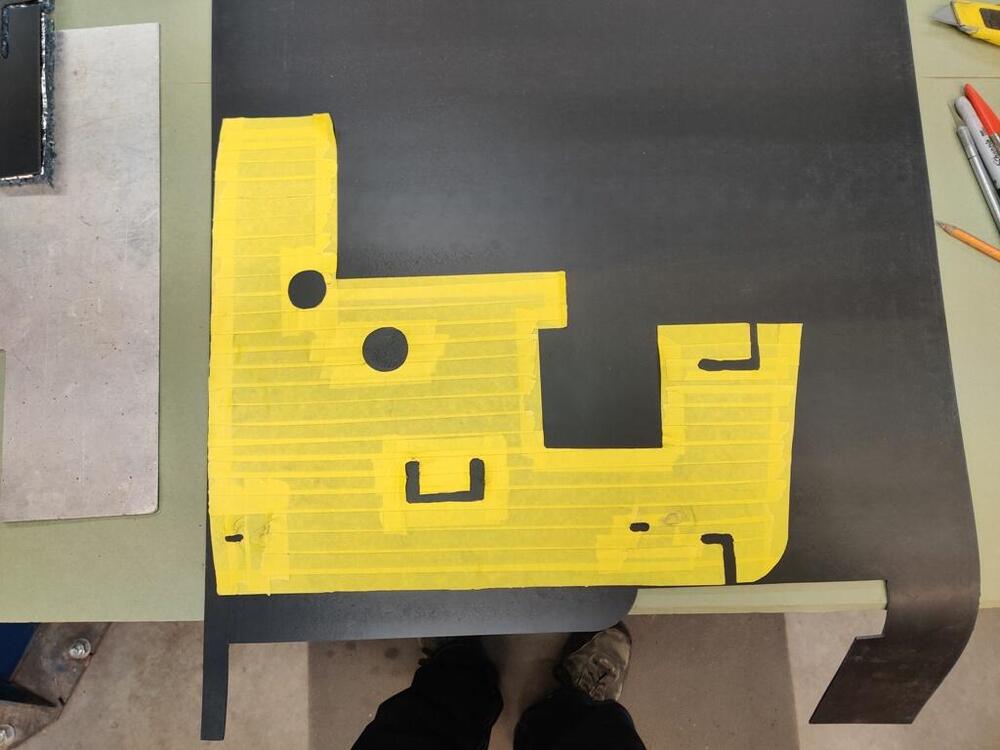

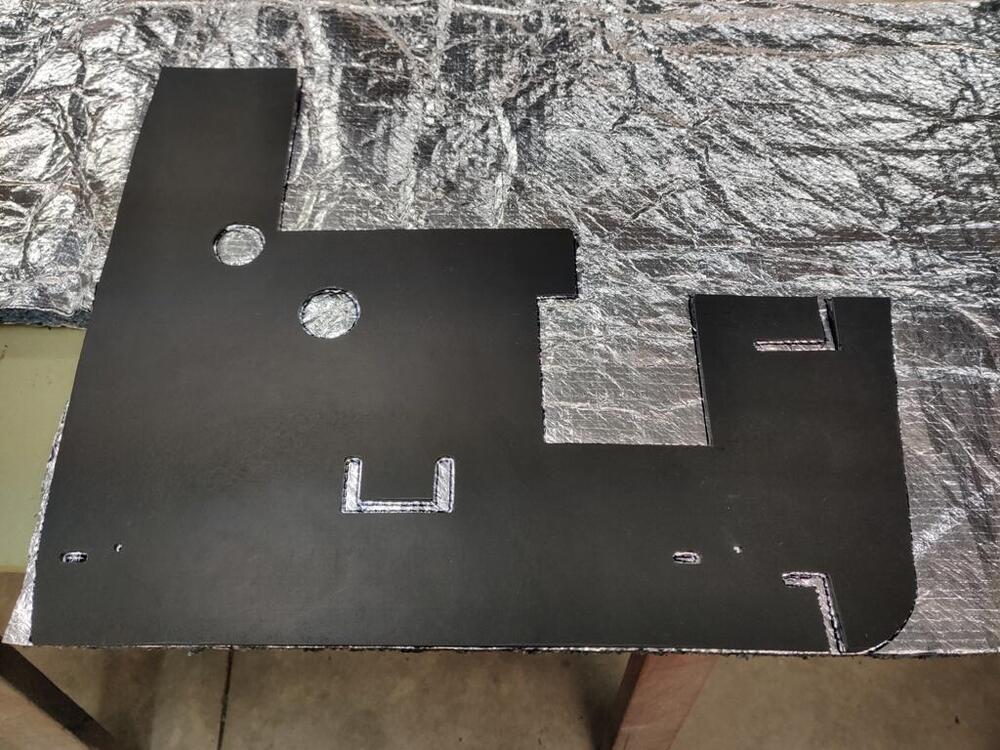

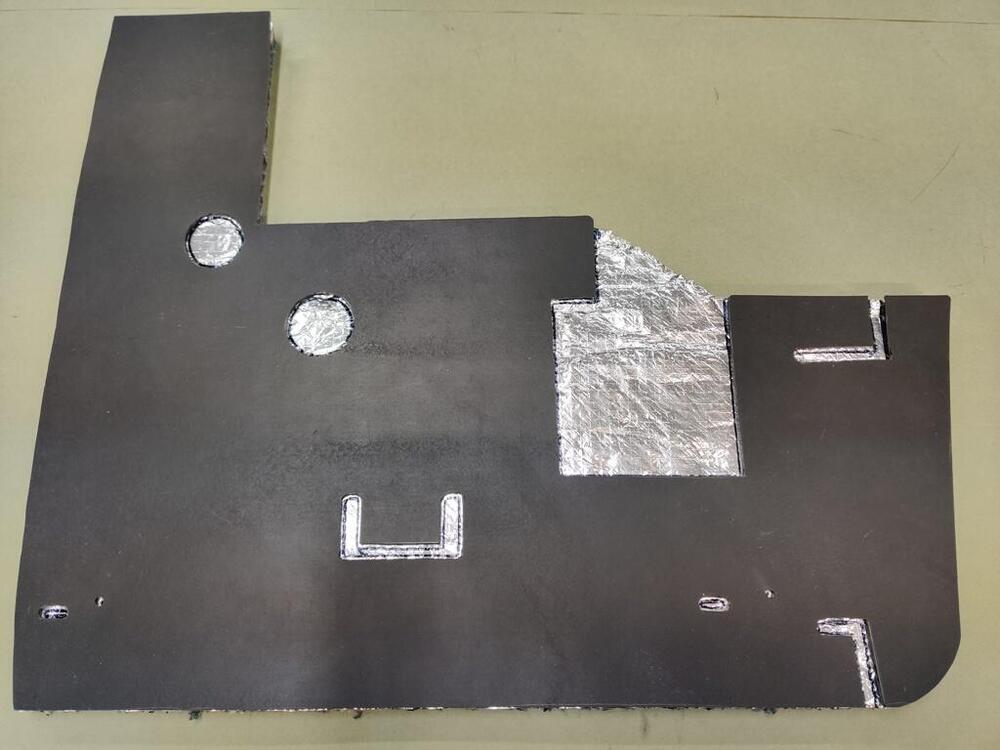

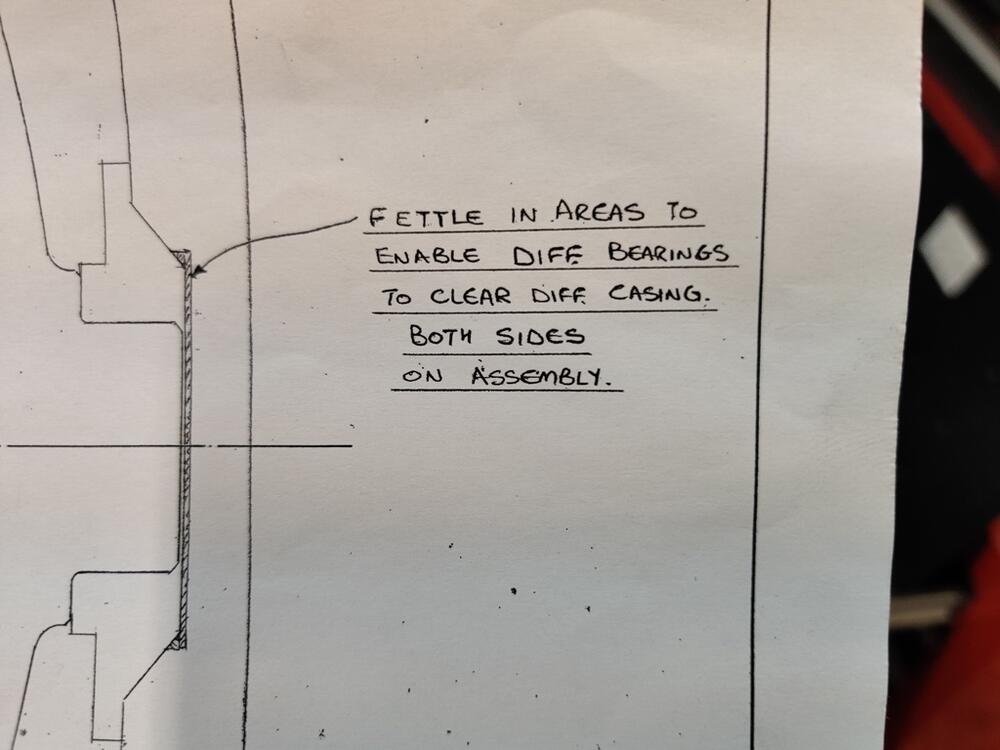

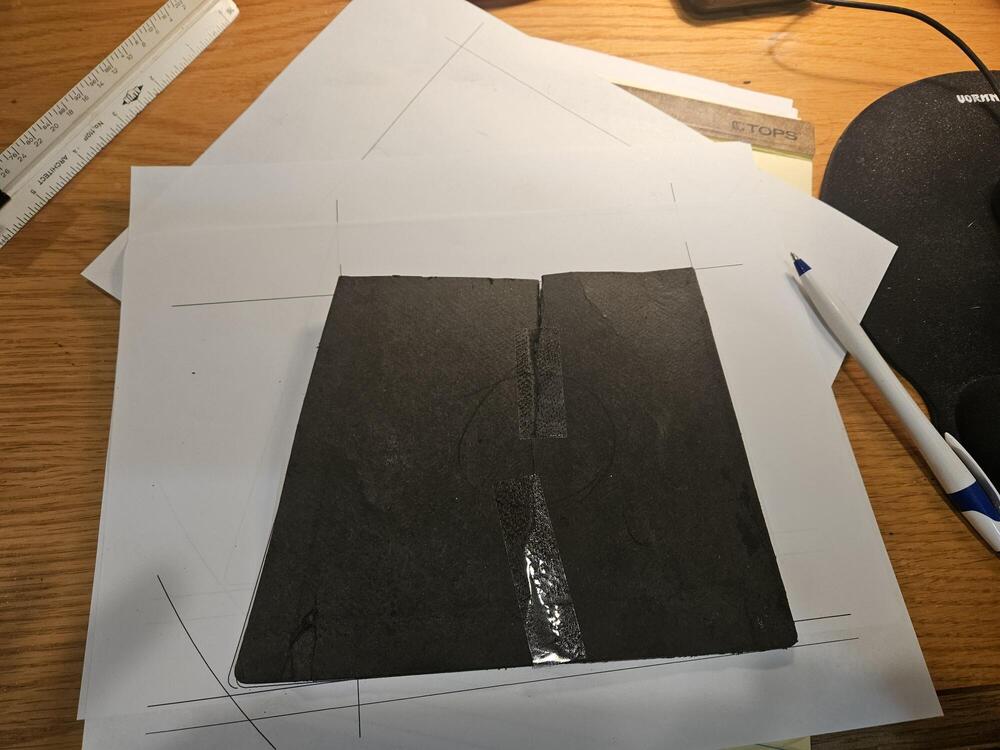

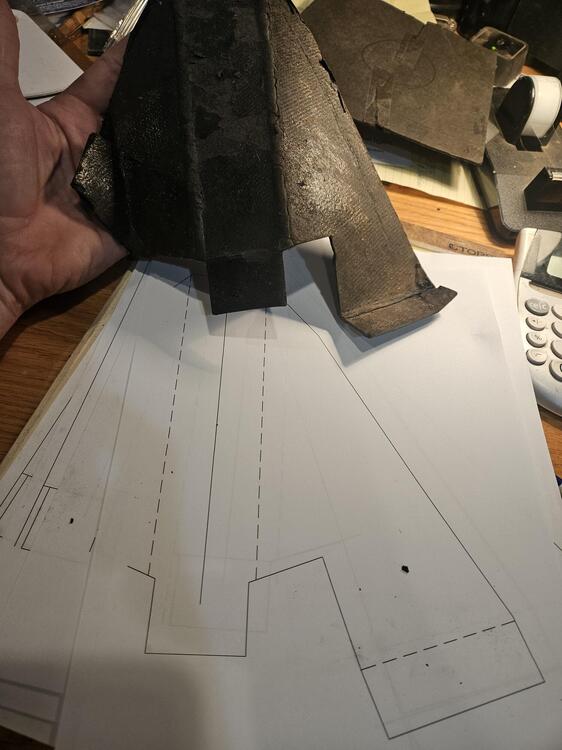

To get the Quaife in the case, it was required to "Fettle":

It took a lot of fettling, but I very carefully ground only where needed until the carrier just fit. In fact, I had to leave one of the main gear bolts off until the carrier was partly in the case, and then torque that last bolt through the side axle opening. This fettling was an unpleasant surprise that added 4 hours of time to grind on the case. I had to be extremely careful with packing the case cavity and other preparation to keep the metal shavings from the carrier and from installed pinion shaft (and bearings).

At this point, and here is where I stopped, I have installed the side retainers, left and right, with their respective shims in their original positions, with the 5 bolts on each just snugged down, not torqued.

Now, I could use some guidance.

What I have not done that I may need to:

I didn't measure the amount of turning force on the pinion shaft. I don't have a suitable tool to measure that. I see that this is supposed to be done without the pinion seal installed. I have already installed that. There is preload on the pinion bearings - I can tell by rotating the shaft by hand. I just don't know how much.

I did not remove the fresh paint (and primer) from the sides of the case where the side retainers seat. I am wondering if those thousandths of an inch matter. Given the side retainer shims originally used are quite thin, paint in this location may be an issue?

I didn't measure the amount of main gear backlash with a dial gauge yet. I just moved the main gear by hand back and forth. Doing so, the amount of movement is noticeable. I'd guess .015" to .020".

I do have a dial gauge and magnetic base and plan to measure the back lash when I pick back up on this.

I was hoping, perhaps naively, that I would be able to use the existing pinion and side retainer shims even with replacing the stock carrier with the Quaife LSD unit, but it looks like I have more work ahead of me. The factory shop manual is difficult to understand, and I don't have the factory tools being referenced.

Anyone have any guidance on how to proceed?

I am thinking about buying the tool to check pinion turning force. I am thinking to not removing the pinion seal, because I would likely destroy it in the process, but instead just factor in 1-2 additional inch-lbs into the reading I measure from having that in place. So, if I measure 2 inch-lbs more than the factory upper limit, I'd call that good, for example.

I am also thinking about removing the paint from under the side retainers and reinstalling them with fasteners torqued to spec to check the main gear lash measurement. From there, I may need to order various side shims and attempt to get back lash correct? Then check the gear mesh pattern to see if everything is set up the way it should be?

Subscriber

Subscriber 7Points1,282Posts

7Points1,282Posts