It looks to me like to aftermarket eBay pieces that you’ve bought have been incorrectly made. They appear to have been stamped out of some type of rubber or foam sheet material. That would make it easy to mistake them for gaskets. In fact, the real OE pieces (called ‘bumpers’) are molded from plastic. The plastic used has a bit of flexibility, but not much (probably made from PVC or Delrin, rather than from styrene). Each bumper's shapes consist of an internal lip and an external flange. The flange forms a shelf on which an actual gasket sits. That gasket can be cut from squishy, closed-cell foam tape.

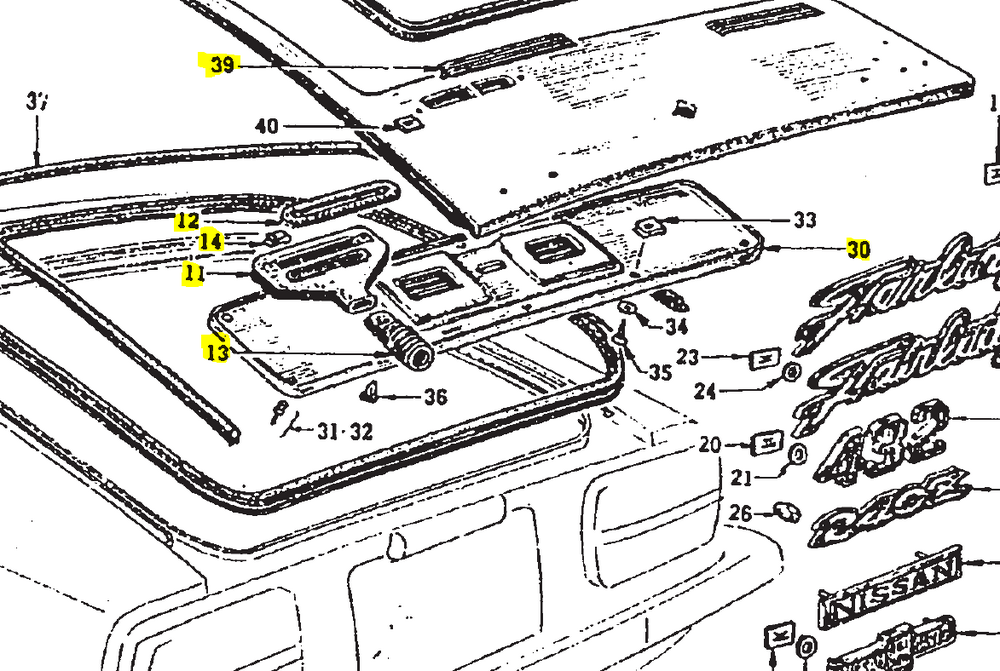

The purpose of the lip molded into the bumper is to make sure that all of the rain or wash water funnels down into the plenum chamber. Without the lip, some of the water could find its way into the hatch cavity as it drips down through the vent, leading to premature rusting around the periphery of the hatch and/or around the hatch window frame.

The purpose of the gasket is to prevent rain/wash water from seeping into the seam between the top surface of the bumper flange and the unpainted underside of the outer hatch sheet metal.

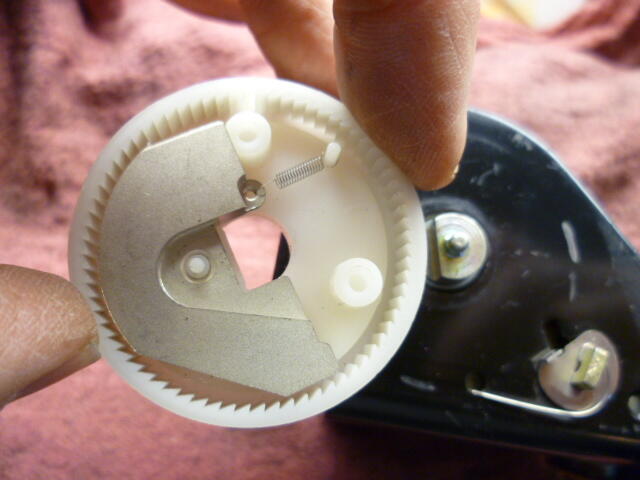

As for the retainer clips, I made mine from scratch (there were no replacement pieces available at the time). They may, then, look a bit different from the stainless clips that you bought. However, I sized the holes in them specifically to accept and grip on the plastic pins that are molded onto the bottom of the chromed-plastic vent trim pieces. There was/is no good way to use screws to hold the vent-gasket-bumper-plenum assembly together. Unfortunately, the pin-into-clip securement strategy means that it will probably prove impossible to remove the chrome vent trim piece after the fact without breaking off the pins.

Here’s the correct assembly sequence:

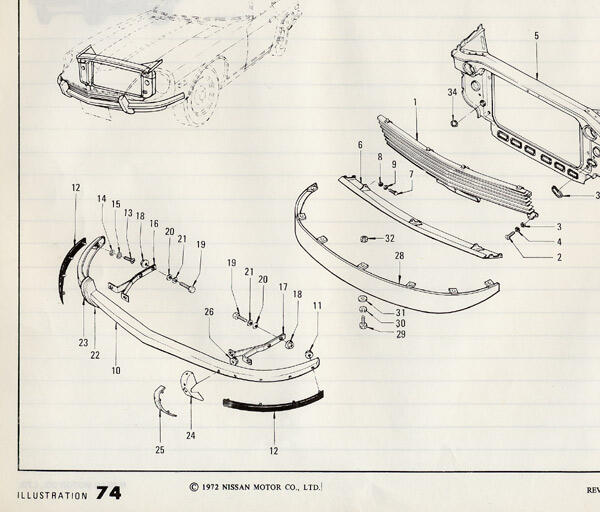

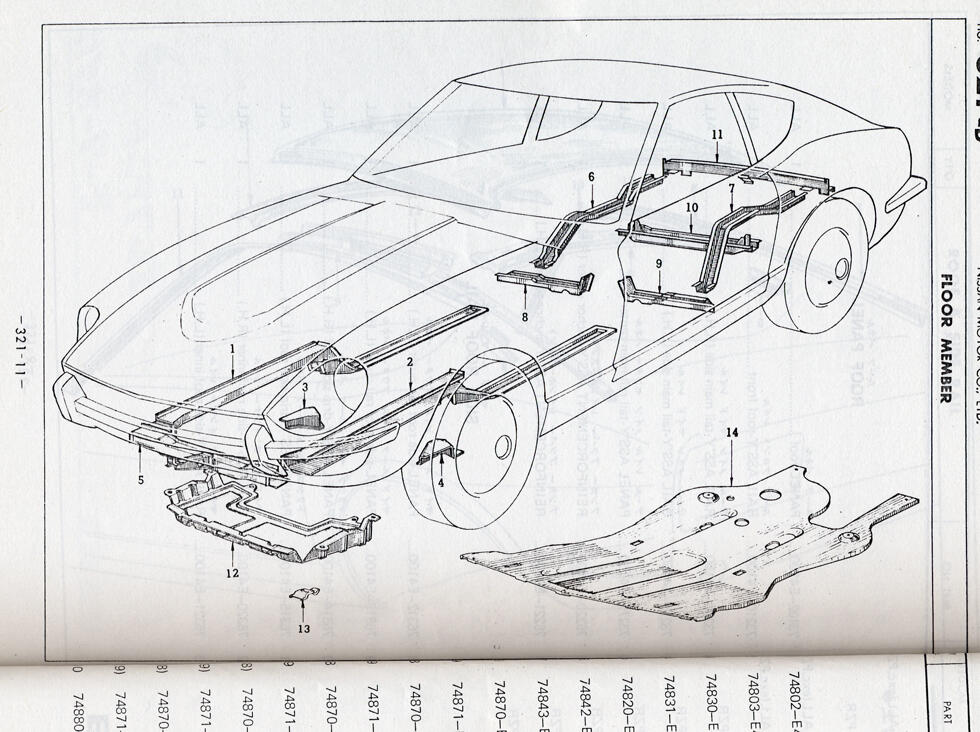

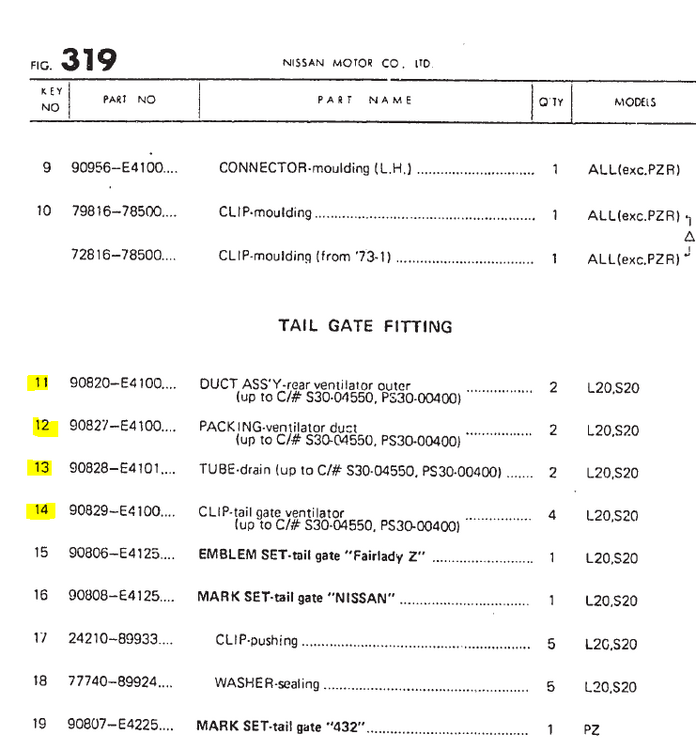

The plenum (#55) goes inside the hatch with the little accordion drains attached to the bottom of the hatch panel.

Then the black plastic bumper piece sits on top of the plenum, with the lip pointed down into the plenum cavity. It looks like the factory used sealant in the join between the bumper flange and the plenum flange.

Then the foam gasket (you’ll need to make this yourself) sits on the upper surface of the bumper’s flange, so that it will end up being sandwiched between the bumper and the underside of the hatch sheet metal.

After all of the mounting holes are aligned, one of the stainless clips get snapped in place so that it sandwiches all four layers: hatch sheet metal, foam gasket, bumper flange, and plenum flange. Repeat at the other end of the vent cutout. The bent lower face of the clip fits inside the plenum. The flat upper face of the clip fits over the outside of the painted surface of the hatch. The compression of the spongey gasket provides some load within the layers, keeping things from rattling.

The mounting pins molded into the back surface of decorative chrome-plastic vents are now pushed into place. No metal barrel clip is used. Instead, the edges of hole in the clip bite directly into the plastic pin. You may need to figure out a way to push on the internal tab of the clip so that it doesn't back away as the pin is pressed into place (i's been a while and I don't remember whether this was a problem or not).

Note: I suppose that the lip around the inside of the bumper isn’t mandatory. However, I hope you can now see the logic in having it there. Making lips for your flat eBay bumpers won’t be too hard. You could even make them using an old inner tube (they don’t have to be stiff – they just need to form a funnel that's long enough to project into the top of the plenum). Once cut to shape, glue each lip into place and make sure the seam where the ends meet is positioned on the top (located at the front when the hatch is closed) of the opening, rather than the bottom.

Note: I’m not sure how thick your eBay ‘bumpers’ are. If they’re too thick (relative to the OE plastic bumpers), you may not have enough room to fit a foam gasket. I suppose that you could use sealant, although assembly might get messy (and taking things apart at some later date would be a pain). Some 1/16”-thick closed-cell neoprene foam would probably work as a substitute (can be found a Michael’s craft centres). Not much give in compression. You may need to layer it to get the right thickness.

Subscriber

Subscriber 3Points428Posts

3Points428Posts