Unfortunately in this instance, the Koni struts I am using have their adjustment done by a nipple at the top of the strut shaft, so no place for an allen wrench there.

I get sick when I look at these pictures, but here we go:

With this close up, they all look like garbage to me other than the few at the bottom which are not accessed because of the material thickness of the spacer, upper spring perch and upper strut mounts respectively. Come to think of it, I might be able to machine a bit off the spacer to raise the shaft a bit (looks like a quarter inch, to access those good threads at the bottom. If the coupler nut can access all of those, and the garbage ones in the middle, along with the "somewhat still there" at the top, then I might be able to salvage this debacle.

The nut doesn't look great, but threads are still mostly there. I have already chase this with a 12M X1.25 tap because I have one. I am waiting on the die to arrive to chase the threads for the shaft.

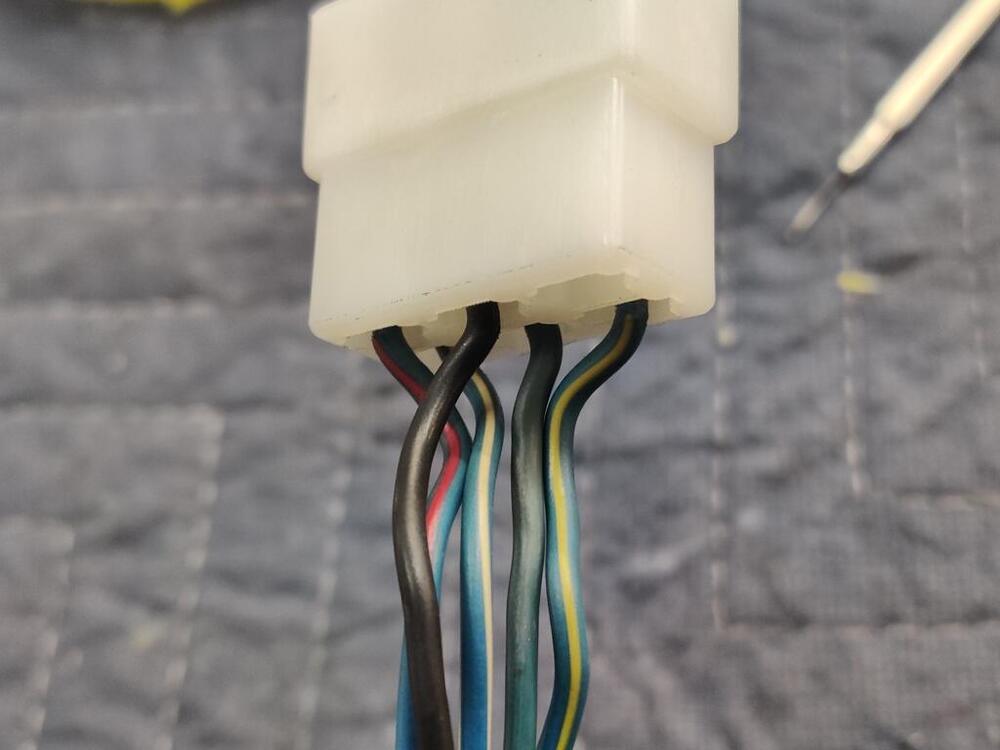

In other news, I gave some attention to the wiper motor, motor mounting bracket, and motor harness tonight. Two of the grommets from 240zrubberparts.com were not as thick as the originals. I chose to use the old ones (just two of four) because there are metal sleeves that go in the center of them. I could have ground the metal sleeves down to match the thickness of the new ones, but my original rubber grommets were in fair condition. So, I used them instead.

The original plastic connector was yellowed with age and brittle. So I replaced that. While doing so, I put on the new rubber grommet for the wiring from 240zrubberparts.com

I was a bit surprised when I opened up the cover for the wiper motor - It was very clean inside. Being a car from Arizona, and off the road/stored for 28 years in Colorado, I think the motor has seen little use. As I found it:

I cleaned the main gear shaft with #000 stainless steel wool, and then lubed the shaft. I probably should do the Honda wiper motor upgrade, but I will see how a fully rebuilt wiper transmission and this motor (with little use) work out first.