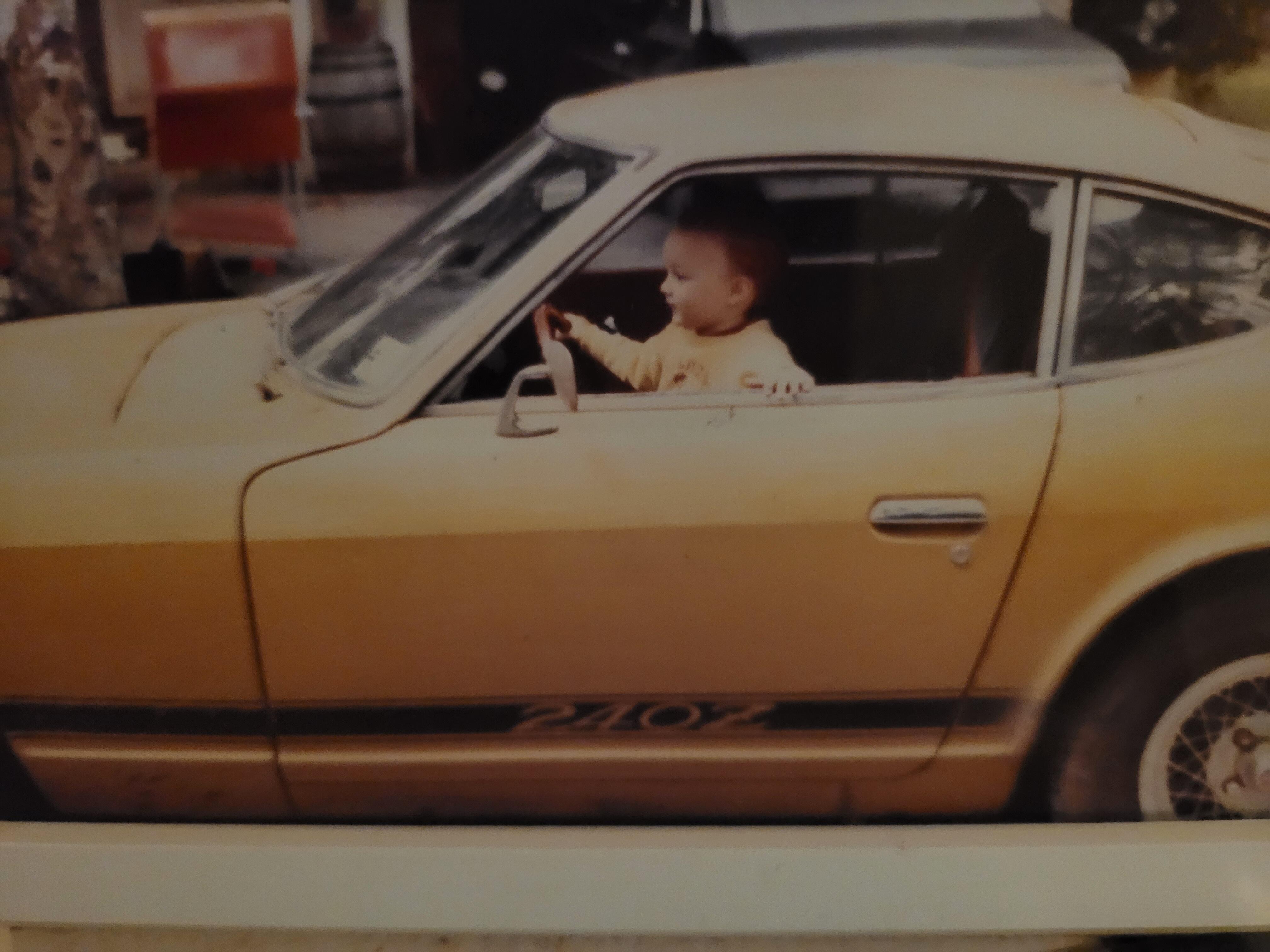

Greetings from Baltimore County, Maryland! I have been a long-time lurker and reader on this site, and I think I may have talked to a few members in person at car shows or chatted online. After searching for years, a few missed opportunities, lost bids on BAT, passing on a few project cars beyond my comfort zone, I finally found my Z in April 2023. As all cars that are 47 years old, she's far from perfect and will need some TLC that my son and I will eagerly perform and enjoy. I will start a project thread to document the work as it progresses. Looking forward to being an active member of this community!

Paul

Subscriber

Subscriber 4Points107Posts

4Points107Posts