Done plenty of all of this. SEM Plastic Prep (not vinyl prep) works wonderfully, It’s primary job is to clean and degrease to remove traces of everything un-desirable. Then use an adhesion promoter like SEM 39863 JUST before spraying the top coat. This softens the plastic and let the top coat stick.

Franky anything that will thoroughly degrease the plastic and clean it without leaving any residue will work. I’ve recently been using generic body shop degreaser to clean, even Spray 9, anything powerful and degreaser-y. Then Adhesion promoter, THEN top coat.

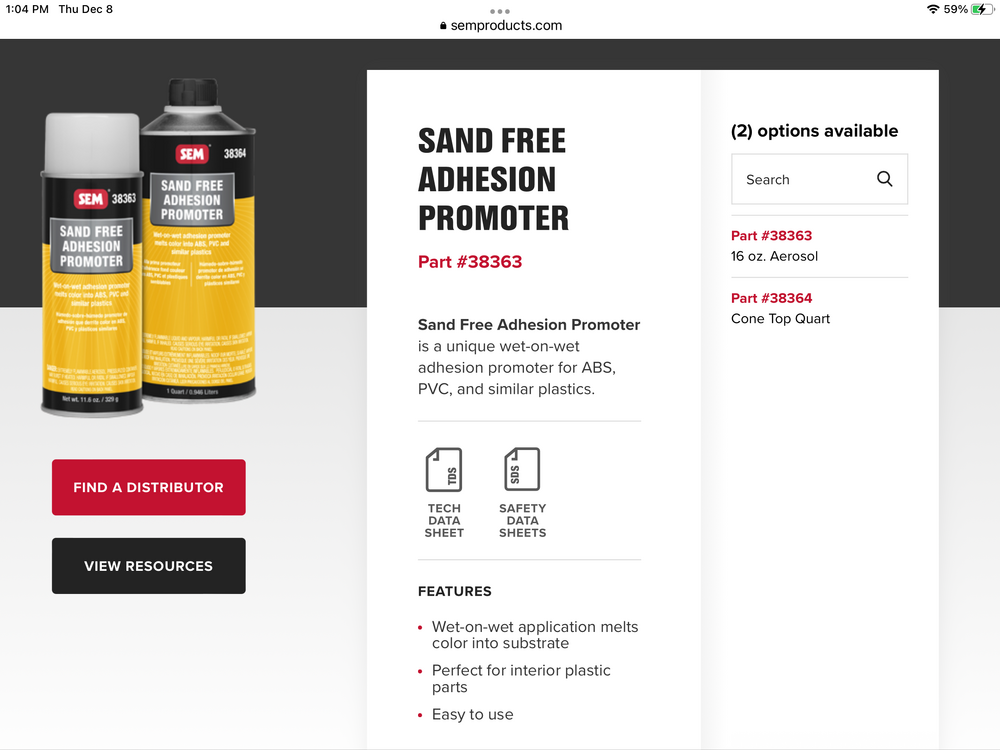

The Sand Free product sounds like a newer development for coloring plastics. I haven’t used it, but the description sounds interesting. PLASTICS only.

Vinyl and leather dying is different. The Vinyl preps typically clean and degrease and do the adhesion promotion all at once. Filthy vinyl, use spray 9 and a scrub brush and water rinse, THEN vinyl prep just before top coat.

Cannot stress enough the need to clean the plastic or vinyl extremely well. None of the top coats stick to 30 years of sweat, body oil and Armor-All worth a damn. Big surprise. I’ve even used Scotch brite pads to scrub to get whatever off da plastic first.

Hope that helps

Subscriber

Subscriber 8Points11,142Posts

8Points11,142Posts Subscriber

Subscriber 2Points2,733Posts

2Points2,733Posts