That is the relief I mentioned. I have worked through many different combinations of spring setups to tune the oil pump for the race engines I build. I’ve used two springs, one inside the other, single springs of varying rates, and made shims to fine tune the pressure in the system.

The rule of thumb for oil pressure, in any engine, is 10 pounds for every 1,000 rpm. So at 5,000 rpm you want to see at least 50 psi, 8,000 rpm (yes, I turn these engines that fast) you need 80 psi.

A couple pounds more is OK, a couple pounds less, not so much.

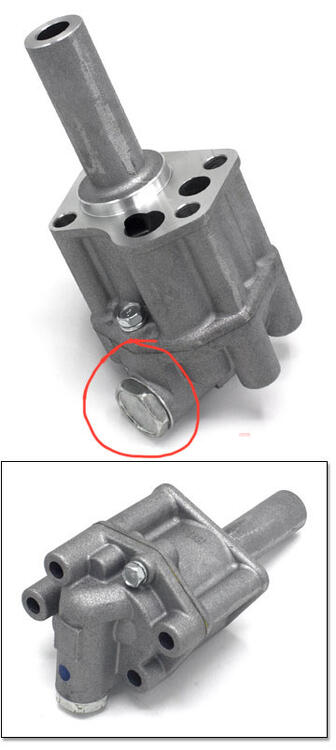

The spring and valve are under the fitting circled in red.