Curious, are your E12 modules Nissan brand or aftermarket? I think that that is one of the issues a person has to consider. The E12 aftermarket does not have much competition so the product quality is sketchy. Look at the price difference on the only two available on Rockauto and then look at the pictures. Who knows what's going on...

https://www.rockauto.com/en/catalog/nissan,1981,280zx,2.8l+l6,1209338,ignition,ignition+control+module+(icm),7172

Anyway, you can get get lost down a rabbit hole when you start modifying things, as you've already found out. Here is a write-up about the HEI module from EuroDat. In short, there are five connections that you need to worry about. Get those five correct and you can put the module wherever you want to. I have seen people put it in place of the E12 module on the side of the distributor.

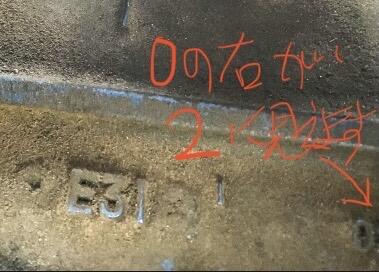

The five points are the two trigger wires, red and green to G and W on the module, the B for battery, the C for coil negative, and the ground contact through the mounting hole.

There is another writeup in the downloads area showing how to jumper the board in the E12 module but it seems overly complex to me. Just extend the green and red wire from inside the distributor.

You have to put your electronics nerd hat on to get in to it.

Subscriber

Subscriber 2Points428Posts

2Points428Posts