So what do we have to do to modify the shift rod?

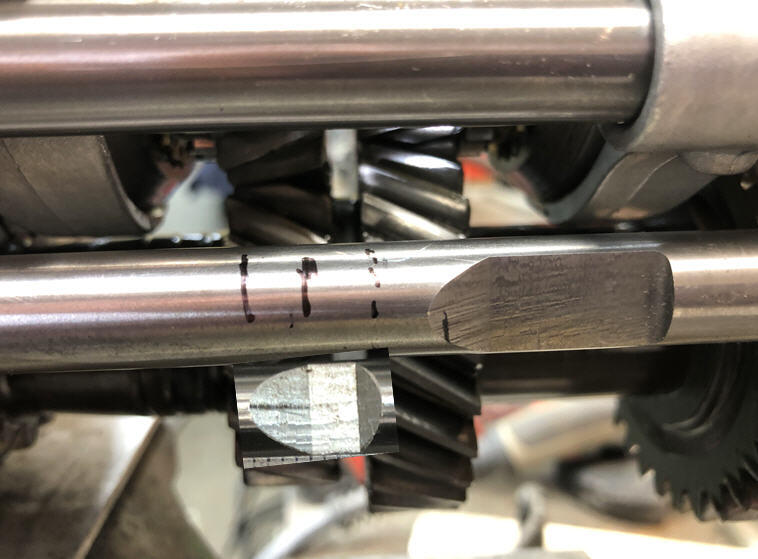

Simple. Here I have sharpied-in the location of the depressed/ramp area on the 4 speed shift rod, onto the 5 speed shift rod. And cleverly spliced and sized a little picture of the 4 speed slot so can visualize how it has to look.

If you just duplicated the 4 speed slot you'd leave an untouch area between the two where the rev lights would be turned on for a second as you shifted into 5th. Would give following drivers pause no doubt "did he just shift into reverse for a second there!?!?!?!" so

So what you need to do, is recreate the "ramp" end where shown, and grind the rest of the meat to the right of that, to be just flat to meet the existing flat area. To say another, just keep grinding the existing ramp away until you have moved it to the left to the left most sharpie line, ie where it is on the 4 speed.

Get your dremel, or your angle grinder, or your carbide tipped grinding burr, and get removing material. I'd start by cutting down at the far left edge of where my new extended flat is going to be (right most sharpy line) and then remove material to the right to create the new extended flat area. Then cut my new ramp.

Clearly you will want to thoroughly wrap the entire guts of the transmission with something like saran wrap or palette wrap or tons of shop towels so that nothing but that short area of the rod is exposed. Chips in here would spell disaster.

You can take the rod out of the transmission of course and remove all that "shavings everywhere" risk, but it means removing the 1-2 and 3-4 rods first, seven little balls and three springs to loose, three cotter pins to punch out and put back, so do what you're comfortable with.

I'm going to go do this work and report back with a picture of the finished modified shift rod.

Precision is not important. The flat part does not have to really flat, the ramp can be smooth or lumpy, it just has to END (get back to un-reduced OD) 2-15/16 ( 2.9375) 74.5mm in front of the center plate with the transmission in neutral. And the flat has to start at 3-3/16" from the center plate so the switch is fully extended (off) when the trans is neutral.

How do you know you are neutral?

All three shift fork channels are lined up with each other perfectly.

Subscriber

Subscriber 5Points3,770Posts

5Points3,770Posts

Subscriber

Subscriber 2Points1,333Posts

2Points1,333Posts