Good stuff. CAD skills to even a beginner degree are something I wish I had.

While I thought I was done with metal work, I decided to revisit a repair I made to the tail light panel where it forms the ledge inside the hatch opening. My repair in the passenger corner was one of my early metal repair efforts on this car. As I am now focusing again on the tail light panel - it has received the least attention so far, I decided that the inside corner areas were not up to par with the rest of the car.

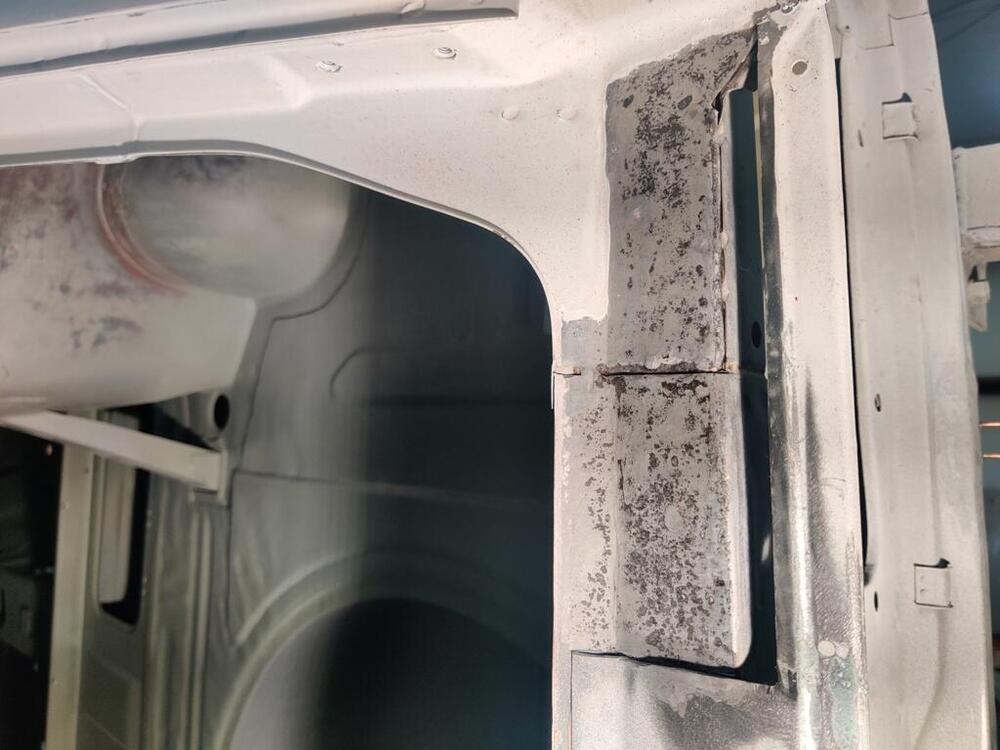

Because the car received a light impact to the rear at some point, the sealer under the ledge had cracked, and gave an opening to moisture. So, in the hatch corners, the metal had obviously rusted in between the panels, causing the ledge (in the corners) to puff up a bit. This area on the left and right is what I am talking about:

After cutting away the old panel sections, and grinding away the rusted metal, I used a chemical treatment to neutralize the remaining spots of rust.

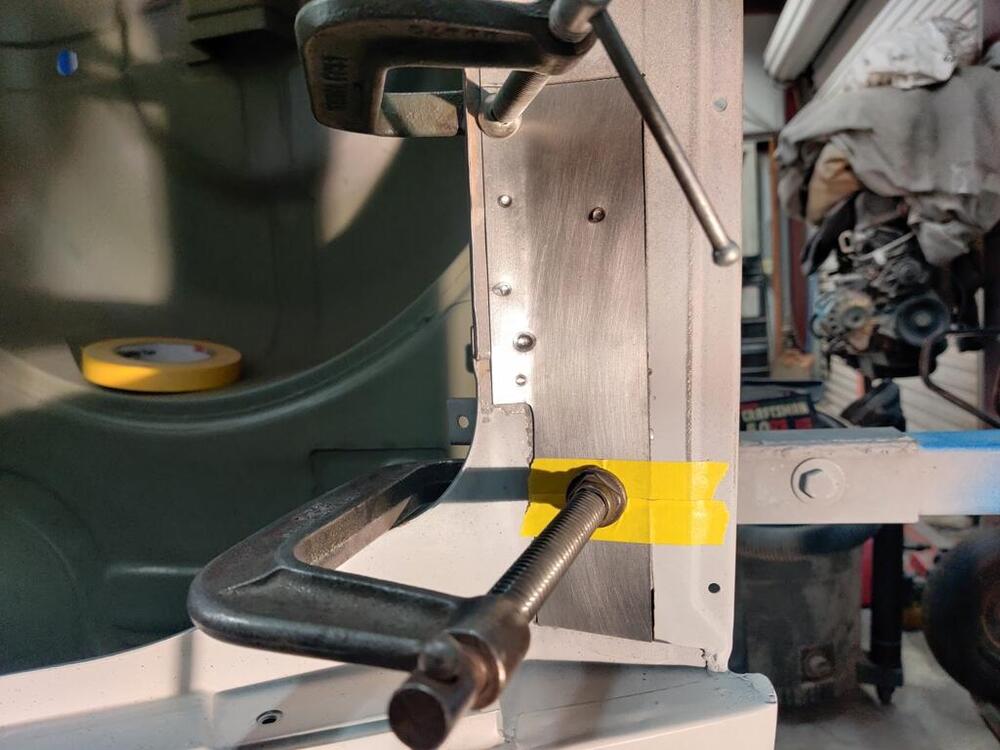

Then, I fabricated a patch panel. I spent extra time getting the fit as close to dead on as possible.

Then, I decided to use the spot welder I bought (a while back now).

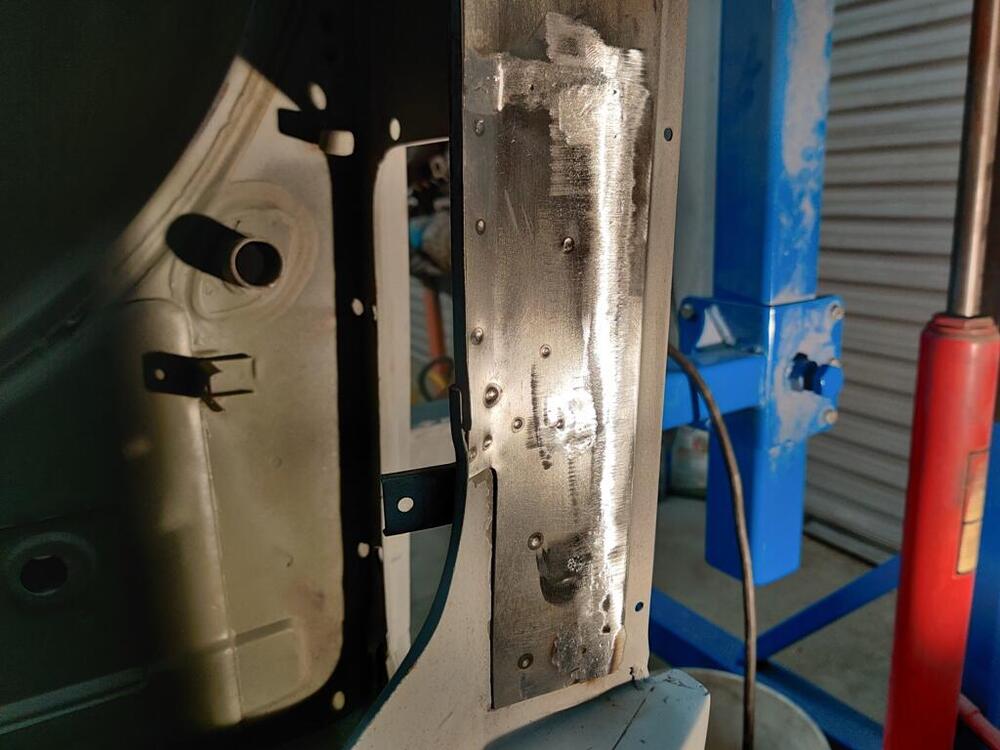

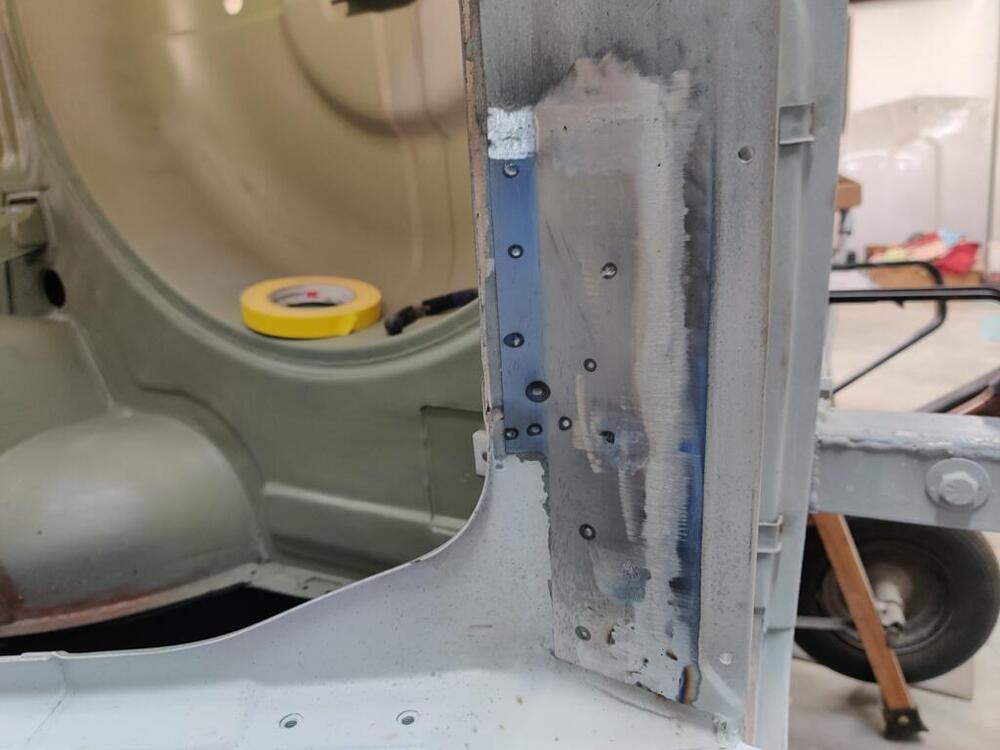

It does a good job, for sure, but when I purchased it, I was hoping it would replicate the factory welds. Unfortunately, these spot welds are notably smaller in diameter. Still a cool tool though. It won't reach everywhere, of course, so I put a few rosette welds (large round welds next to the mig weld seam) to finish putting welds back in the factory locations. Most of these spot welds are in the factory locations, but I also put a couple of extra ones. 🙂 A whole bunch of pictures follow:

After grinding away the extra, I used 80 grit on a DA Sander to give the entire repair area a nice texture.

I feel better about this repair than leaving it the way it was. Now, I just have to repeat for the right side. It will take several hours.