You know, I relate to what you are saying! Many of us tend to over analyse / over think these things. They seem scary at first until you actually do the job and find it was a lot of fuss over nothing! 😉

Don't know the brand, but given that you are only doing 1 job with that tool and you're not a professional mechanic doing many of these every day, I think it will be just fine for your purposes.

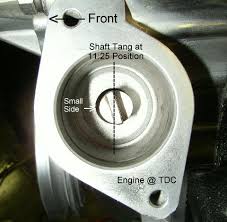

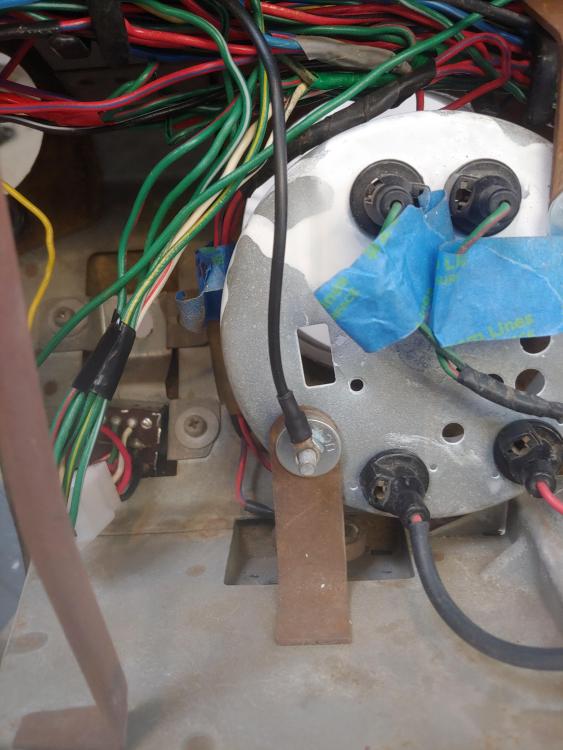

Don't go buying bolts etc. If you bring cyl 4 to compression TDC (both ex and intake cam lobes pointing up) and use the rope or compressor method, you won't be losing your valves. If I recall correctly, you literally have mere millimetres of valve to piston clearance, so it's very very unlikely that you will be loosing the entire stem down the valve guide without being able to recover it. I await someone to correct me. The compressor (or rope) just helps keep the valve at the top (shut) so that you can easily put the springs / caps etc back on.

If you want to buy any additional items, get a new cam cover gasket - a decent one that doesn't fall apart, so that you can reuse it when you next take the cam cover off. Don't forget to scrape off / clean up the residue from the old gasket first as some of them leave pieces of themselves behind. Also make sure any residue doesn't end up in your oil.

https://www.thezstore.com/page/TZS/PROD/classic12a13/10-2491C

This is not a Z car, but a very good video - I like the Vaseline idea!

Subscriber

Subscriber 3Points383Posts

3Points383Posts