Hi,

I bought a spot welder: a HTP Quick Spot II spot welder (along with a Tig welder) over the Black Friday time period (sale still going on now fyi) and was asked by someone reading my "bringatrailer" 240z build thread to share some information about it after I got it up and running. Well, here goes:

Here is the spot welder. The special offer is currently $300 off on qualifying products when you buy the Tig welder. This spot welder counted as a qualifying product, so that is nice...

It comes with the copper arms and tips you see in the pic. These are good to get you started with making spot welds in basic configurations. USAWeld sells other tip configurations if you need to spot weld different areas that these tips won't reach. There is a control panel which allows you to choose parameters for different welding situations. The settings from left to right in the picture below are basically "on/off pulse power" vs. "continuous" power, selection of thickness of metal being welded, and fine tuning of the duration of weld operation. There is also a pressure setting, which adjusts the amount of pressure the two contacts close upon the sheet metal with.

The pulse operation can be used for high strength low alloy, galvanized, or weld thru primer coated metals according to the manual. It uses time between heat pulses to burn away contaminants for a better weld. Continuous can be used for clean metal. You follow the guidance in the manual and set the second setting based on the total thickness of the panels being welded.

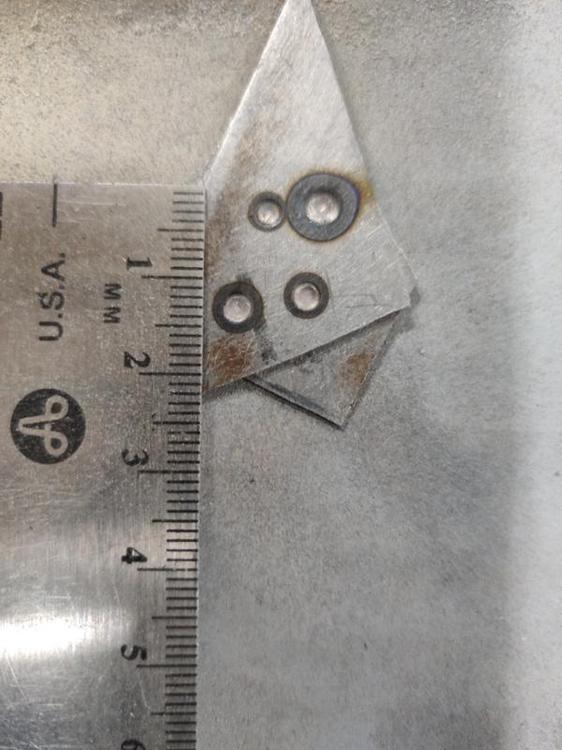

In the next pic (I only did one sample piece) the welds correspond to the following settings:

Weld order from top left to right to bottom left to bottom right is: 1, 4, 3, 2:

Weld 1: (top left): 175 lbs, continuous, 1 mm + 1 mm, and default duration

Weld 2: (bottom right): 265 lbs, continuous, 1 mm + 1 mm, and default duration

Weld 3: (bottom left): 265 lbs, continuous, 1 mm + 1 mm, and 1 step up from default duration

Weld 4: (top right): 265 lbs, pulse welding, 1 mm + 1 mm, and maximum duration

If it isn't apparent, you should notice that the size of the spot welds is quite small. That is, the diameter of the "divot" is much smaller than that of the factory spot welds on our Datsuns. Here is a reference image:

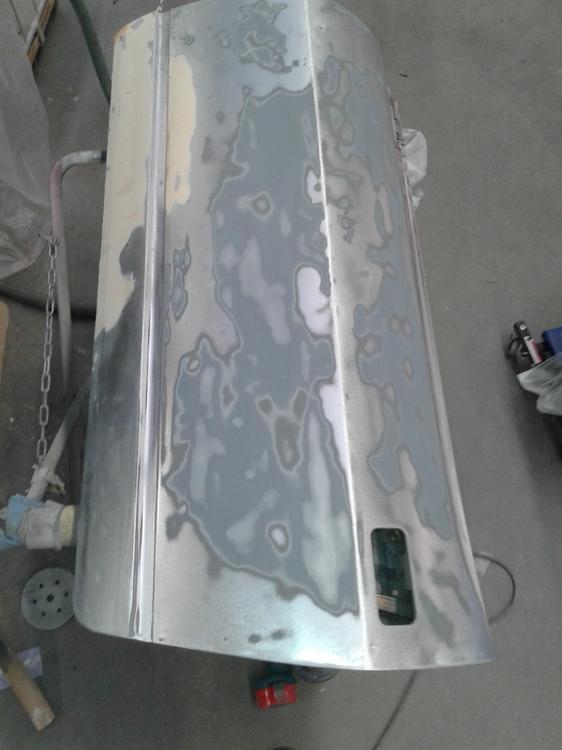

The factory spot weld on the lower edge of this rocker of my 240z (apologies if it is hard to see) is about 5 mm in diameter. The largest of the example welds done above on the test piece is about 4 mm. Here is another reference photo:

So, a ready made observation is that the HTP Quick Spot II isn't going to replicate the 240z's factory spot welds. However, it's kind of close... and if the performance is as good as shown in the video below, then maybe getting factory "performing" spot welds is a box that can be checked with this welder. And perhaps making them look factory is pretty easily done with a bit of creativity? I'll be exploring that coming up in the new year in my 240z build thread, if your interested in checking that out.

Hope this helps someone.

Garrett

Subscriber

Subscriber 3Points1,282Posts

3Points1,282Posts Subscriber

Subscriber 2Points3,770Posts

2Points3,770Posts

.jpg.e1e3038e1d21d4954c3b053f3e4adafc.jpg)