All Activity

- Past hour

-

Z Restoration Progam

'Gork' is - as any fule no - Grok's stupid cousin. Garbage in, garbage out.

-

Z Restoration Progam

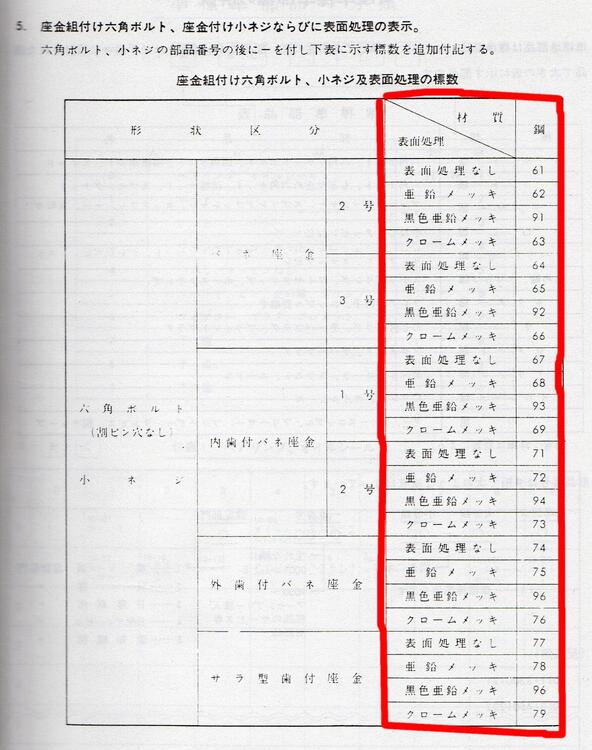

...or you could just try reading the Nissan Engineering Standards specifications for electroplating fasteners as used on the S30-series Z range, as published by Nissan Japan from 1969 onwards:

-

Z Restoration Progam

No, you're just being obtuse now. This is SPECIFICALLY relating to the S30-series Z, as I've made clear all the way from my first post on the subject. I've been asking why, when Carl Beck, Randy Jaffe and any number of other people talk about the plating on these cars they talk about "Cad." as though that was the original spec, when in fact it's not Cadmium. No. Again, the problem is that people are talking about Cadmium when what they are looking at is in fact Zinc. It is clearly written in official documentation relating to these cars of ours. Have our gurus looked? It appears not. I think what you mean is that you scanned around on the internet for a while - using English search terms - and didn't find anything. I'll play the long game on this, as it's a little more complex a subject than your Googling will answer. Stay tuned... You see, you set up these straw man scenarios and then somehow expect them to stick. Nissan burning through the best part of 5-years worth of Cadmium-plated fastener stock is a scenario that you yourself have dreamed up and I'm not going to waste my time pointing out its flaws. It is half-baked nonsense. Remind me, what were the proposed possibilities? Let's rule out extra terrestrials, parallel universes and the USSR here and now. Why didn't he look in the literature for his answer? Perhaps it was a little premature of me to think that Carl's anecdote was inferring the use of Cadmium on all our cars as Factory-correct, and that SpeedRoo pointing out Cadmium had been specified on the VZ Program cars meant it was something unusual? No. On the contrary, that's exactly what I believe were the points being made. Let's cut to the chase here. Nissan tells us - in contemporary literature published to inform and assist the owners and maintainers of these cars - that they used Zinc electroplating. There's no mention of Cadmium. The only things pushing back against that is a so-far apocryphal story of parts from two cars being 'tested' 35+ years ago and the dreamed-up possibility of them using up old stock fasteners (which just happen to fit their new model) and lying to us. It's pretty flimsy stuff, to say the least.

-

Z Restoration Progam

No absolute answer... but interesting non the less. ASK gork: "What can you tell me about Nissan Motor Company using Cadmium plating on automotive fasteners in the 60’s and 70’s?” response below. Information specific to Nissan Motor Company’s use of cadmium plating on automotive fasteners during the 1960s and 1970s is sparse, as historical records and available sources do not provide detailed documentation on Nissan’s fastener coating practices during this period. However, based on general industry trends and the limited information available, here’s an informed overview:Cadmium Plating in the Automotive Industry (1960s-1970s): Cadmium plating was a standard practice across the automotive industry during the 1960s and 1970s due to its excellent corrosion resistance, lubricity, and predictable torque-tension characteristics. It was particularly valued for protecting steel fasteners (bolts, screws, nuts, etc.) in harsh environments, such as exposure to road salt or marine conditions, and for its compatibility with aluminum components, which was critical in automotive applications to prevent galvanic corrosion. The plating’s gold or yellow iridescent finish was common on fasteners in vehicles from this era, including those produced by Japanese manufacturers like Nissan.Nissan’s Context in the 1960s and 1970s: Nissan, operating under the Datsun brand for many markets during this period, was expanding globally, particularly in the U.S. with models like the Datsun 510, B210, and 240Z. These vehicles were designed for affordability, reliability, and fuel efficiency, especially during the 1970s oil crisis. While there’s no direct evidence in the provided sources confirming Nissan’s use of cadmium plating, it’s highly likely that Nissan followed industry standards and used cadmium-plated fasteners, as this was the dominant coating for automotive fasteners at the time. Cadmium’s properties, such as its ability to resist corrosion in marine and alkaline environments and its low-friction characteristics, made it ideal for critical components like bolts and brackets in Nissan’s vehicles. Environmental and Regulatory Shifts: By the late 1970s, concerns about cadmium’s toxicity and environmental impact began to emerge. Cadmium is a heavy metal and carcinogen, and its use in manufacturing posed health risks to workers and environmental challenges due to waste disposal. While European regulations like the 2000 End of Life Vehicle Directive (ELV) and the 2006 Restriction of Hazardous Substances (RoHS) directive later restricted cadmium use, these concerns were already prompting automakers, including Nissan, to explore alternatives like zinc plating or zinc alloys in the 1970s. Nissan’s commitment to reducing environmental-impact substances, formalized in 2007, suggests that by the late 1970s, the company was likely transitioning to less toxic coatings like zinc-nickel or zinc phosphate, especially as it expanded manufacturing in regions with stricter regulations. Nissan’s Manufacturing Practices: Nissan’s manufacturing facilities, such as its Cuernavaca plant in Mexico (established in 1966) and later the Smyrna plant in the U.S. (1980), focused on producing vehicles like the Datsun 510 and B210. While specific fastener plating details are unavailable, the industry’s reliance on cadmium plating during this era implies its use in Nissan’s assembly processes, particularly for components exposed to corrosive conditions, such as underbody fasteners or engine bay hardware. The lack of specific documentation may reflect the standardized nature of fastener coatings, which were often sourced from suppliers adhering to industry norms rather than being a proprietary Nissan process. Comparison to Ford: Like Ford, Nissan likely used cadmium plating for its corrosion resistance and mechanical properties but faced similar pressures to adopt alternatives as environmental regulations tightened. Ford’s struggles with rust prevention and slower adoption of advanced coatings like E-Coat suggest that Nissan, with its focus on economical vehicles, may have prioritized cost-effective coatings like cadmium initially before transitioning to zinc-based alternatives. Conclusion: While direct evidence of Nissan Motor Company’s use of cadmium plating on fasteners in the 1960s and 1970s is not explicitly documented in available sources, it is reasonable to infer that Nissan, like other automakers, used cadmium plating for its fasteners due to its widespread adoption in the industry for corrosion resistance and lubricity. By the late 1970s, Nissan likely began shifting to alternatives like zinc or zinc-nickel plating as environmental concerns grew. For more precise details, contacting Nissan’s heritage division or automotive restoration communities specializing in Datsun vehicles from this era might provide additional insights. - - - - - - End Quote - - - - - - - - -

- Today

-

Z Restoration Progam

Is this like Datsun saying the hooded map light was one of the changes for 21000 and beyond yet 2 of us with 12/70 cars have hooded map lights. I would think it possible for Datsun to document zinc if that was the direction they were going but I could also see them using up cad NOS if they had it.

-

Z's on BAT and other places collection

Looks like post 79 ZX wheels

-

Options for series 1 dashboard area above hazard switch?

Every single one...

-

cooling fan blade condition

Could well be -> intercooler, -> condenser, -> Koyo radiator (stacked up before the) -> fan. (unfortunately don't have a shroud - wish I did) Plus Phoenix softens up a lot of plastic at times (then dries it out, bakes, and cracks it). And I believe the blade length played a part in my particular case.

-

Z Restoration Progam

Sounds like the argument for god. "Yes Darwin, Einstein et al, you may have shown how everything that is may have come from nothing, but you've not proved that Nissan didn't ship any cars with cad plate bolts in the 70s"

-

zed2 started following Interesting electrical issue- Series one car......

-

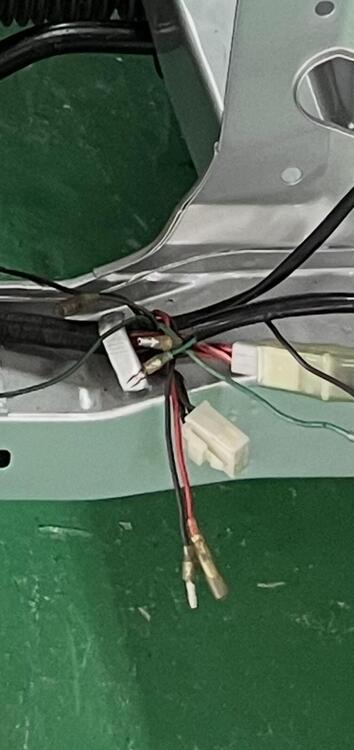

Interesting electrical issue- Series one car......

-

Z Restoration Progam

That's a philosophical question. No simple answer... It wasn't just a materials lab. It was a very reputable high tech company that he worked for, that had its own internal materials lab. Very common for large research-based corporations. And, you can see that he's not claiming that all 240Z hardware was cadmium-plated. He's suggesting that some of it might be. He writes very clearly. I think that his words have been distorted a bit throughout the cadmium conversation, trying to make a gray situation black and white. Sometimes you just have to live with the uncertainty. And be careful, as Carl suggests, if you're not certain. There might be cadmium. Our History

-

Z Restoration Progam

It seems to me a lot of weight is being put on what Carl Beck reported of what someone at a materials lab 35 years ago told him. What if the guys in the materials lab were busy, stuck Carl's bolts in the drawer and fobbed him off when he came back? Why would anyone believe such an anecdote in the face of a document from Nissan at the time saying what they used? Just as OEMs today thoroughly check suppliers work against the spec, I'd be very surprised if Nissan in the 70s accepted cad plating when they'd specified zinc.

-

Z's on BAT and other places collection

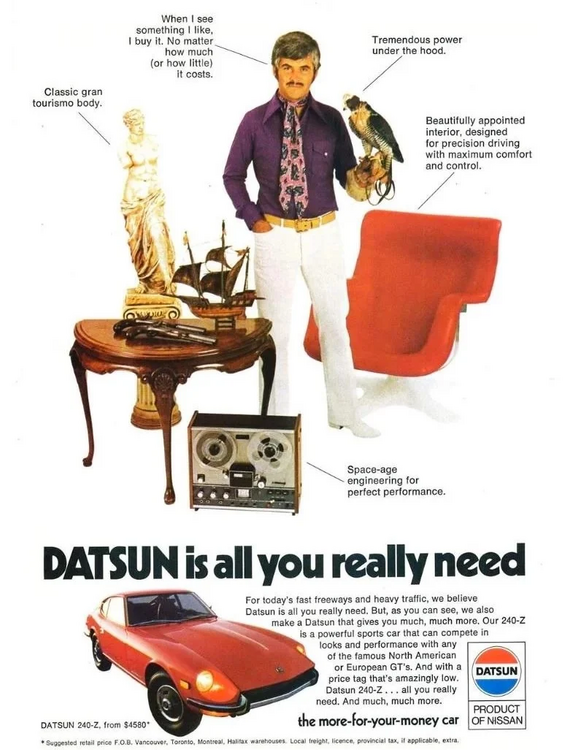

Image search shows a couple of social media post pushing the ebay sale. This add was included in one. I've seen it before but it's still funny to me. SilodromeIncredible Barn Find: An Early Datsun 240Z With Just 7,00...This is an early Datsun 240Z that was built in the first year of production - 1969 (1970 model year). According to the seller it has just 7,000 miles from

-

Interesting electrical issue- Series one car......

Then I would guess that with the electronic flasher it makes no difference since it's not load related. And in the case of my all LED bulbs the load (even with all 8 hazard lights blinking) is insignificant.

-

Z's on BAT and other places collection

I wonder why the seller doesn't at least blow the crap off of the car. Looks like the tires are holding air, he could even roll it out the front of the shed/garage. Looks like they're going for the "barn find" mystique. Or hiding the Earl Scheib paint job. Weird stuff.

-

Z Restoration Progam

You wrote it yourself. Up above where you showed that cadmium was used through 1964. Cadmium was commonly used as a plating material in the automotive industry. It was so common that the shortened "cad" was used to describe plated parts. The problem is that the transition away from cadmium has not been clearly communicated. And assumptions have been made, like the claim that cadmium was banned in Japan. No written documentation of that seems to exist, for the time frame of the transition. The transition away from cadmium seems to be more anticipatory, expecting future bans, or limiting future liability. It was a choice, and therefore there was no regulatory reason not to use it. Ran out of zinc-plated stock? Use the old cad stuff. It's legal. Write up a QA exception. (Manufacturing world realities). The open question is about the parts that Carl Beck had tested at Honeywell. Did they come from a 240Z? Were they original to the 240Z? How did they get there? Possibilities have been proposed. Nobody has said that all 240Z's used cadmium-plated parts. Only that cadmium-plated parts were found on a 240Z. Not the same thing. The cadmium question exits on other car forums. Just as entertaining. Lots of misinformation. https://forums.pelicanparts.com/porsche-911-technical-forum/164007-metalurgists-educate-me-please.html

-

kats started following Options for series 1 dashboard area above hazard switch?

-

Options for series 1 dashboard area above hazard switch?

Hi! Additional info, our cars naturally have power source for the fog lights in the wiring harness. Kats

-

Z Restoration Progam

But - again I ask - what's the origin of the "It's Cad" narrative relating to the Z? Where is it actually written? I see no source except long-held belief which appears to be built on presumption. Looks like the goalposts are being moved again. The whole point of the N.E.S. Nissan Engineering Standard was to ensure that fasteners could be specified and supplied to a fixed - trusted and repeatable - system. I've already given an example - from a Z-specific factory parts list - of the way an NES part number suffix could denote a particular finish (Zinc electroplating in the example I gave) on a given class of fastener, and it applied over the whole range of Nissan products in the period we are talking about. Nissan would have been using tens of millions of such items in their manufacturing operations, so it was natural for them to have a system to support that and huge manufacturing facilities for pieces to that standard. To imply that there was some sort of back door where Cadmium-plated parts slipped into the supply chain - and specifically on the S30-series Z car's production process - seems desperate to me. And "outsourced"? You remind me of Carl Beck telling us that Nissan Shatai was nothing to do with Nissan and that Nissan had 'outsourced Z production to a different company'. Such musings don't seem to take into account the complex interlinked structures of Japanese Keiretsu. https://nissan-neji.com/

-

Z Restoration Progam

Thanks for noticing the Shakespeare quote and the intention. I think all this really does matter. It's not going to cure cancer or bring world peace, but it is one of the things we have traditionally done here on this forum and drilling down into the details like this helps us to understand the cars better. Well said. Yes, sometimes the exchanges are less than pretty but that is the type of thing that happens when somebody pokes their head above the parapet and questions the status quo. I often remark that such exchanges may give off a fair amount of heat and noise, but also a little light.

-

geo74 joined the community

-

Options for series 1 dashboard area above hazard switch?

cool stuff, was thinking of adding a blue tooth device to my sony stereo. Might check into that. I love the switch, I have driving lights on the front, and the switch is by the rear defrost switch, since the bezel has the light indicator there. Was thinking of an indicator light to go in above the hazard switch..........

-

Let's show vintage racing pictures. I'll start.

-

Let's show vintage racing pictures. I'll start.

-

Options for series 1 dashboard area above hazard switch?

100% agree with Jim. I did install a relay and used LED bulbs for the fog lights.

-

The OG 240Z - Reanimation Project

Hahaha!! I'm hoping it won't come to that! ☺️

-

Interesting electrical issue- Series one car......

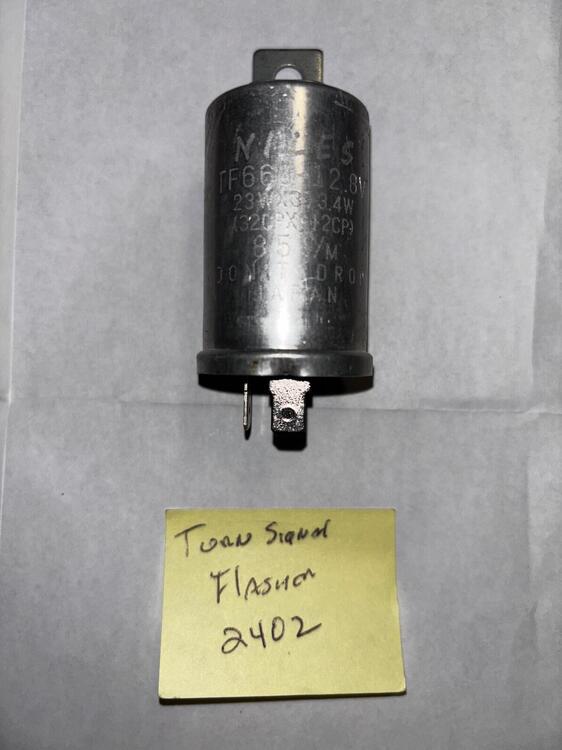

I thought I had pics of both flasher units (turn signal and hazards), but I can't find them. Memory says there are markings on the outsides of the cans that indicate how many filaments each one is designed for.