Everything posted by Jeff Berk

-

Does an LSD need better cooling?

I don't fully understand the process but I'm sending the caster a 3D printed part for them to create the mold. Its tempting to visit the caster's forge but its a 5-hour drive.

-

Does an LSD need better cooling?

That adhesive is about $100. I actually have some conductive adhesive for attaching aluminum heat sinks to electronic components. I might give that a try and see if it helps during an Auto-X (and see if they stay attached).

-

Does an LSD need better cooling?

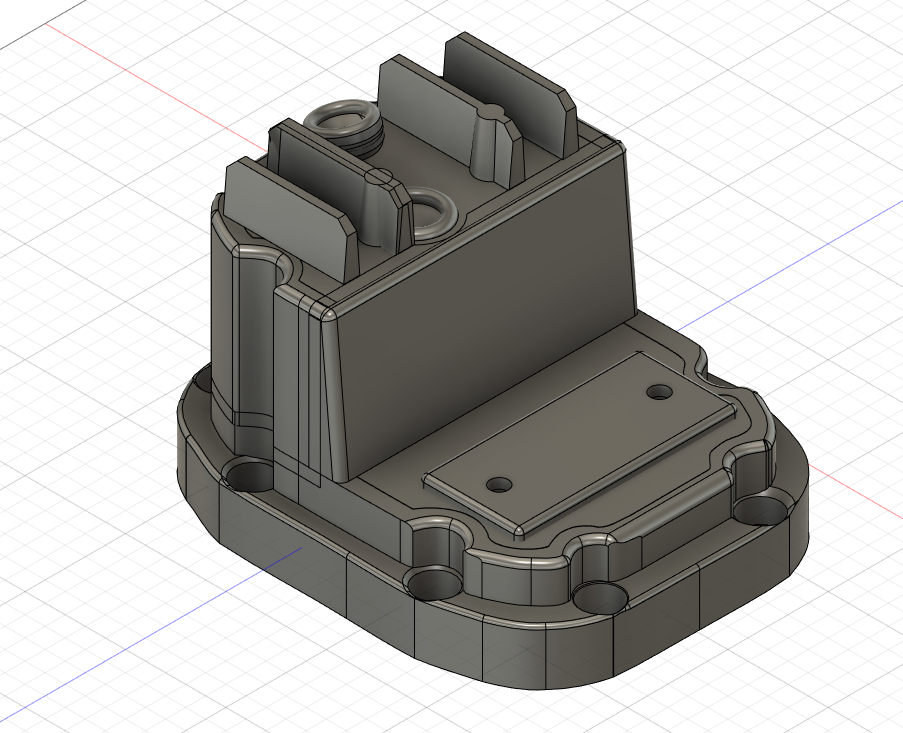

I did look at the Banks video and borrowed some ideas from it like adding an under differential air deflector. His temperature studies also was the reason why I added a temperature sensor to the fill plug. I'm planning on using the original diff cover and observe the temperature during one or two Auto-X events. After that I need to change the oil and I was then going to try the new cover and see how it impacted the temperature measurements.

-

Does an LSD need better cooling?

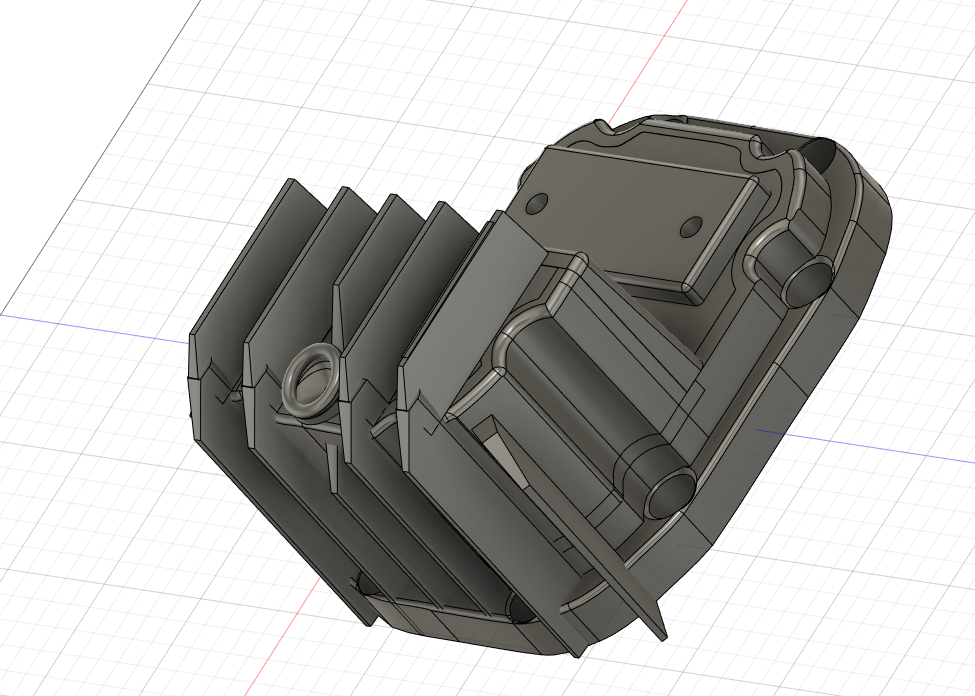

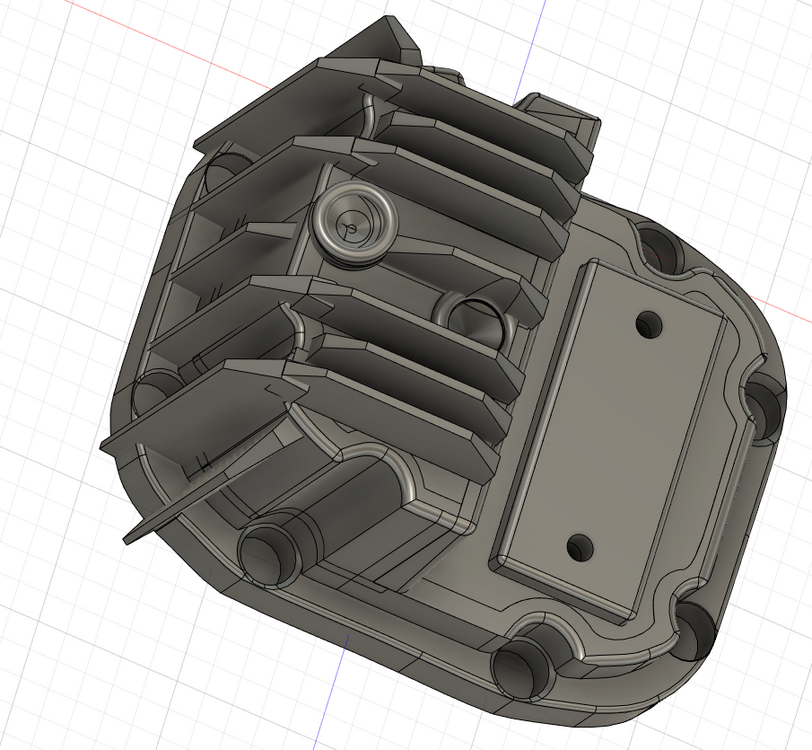

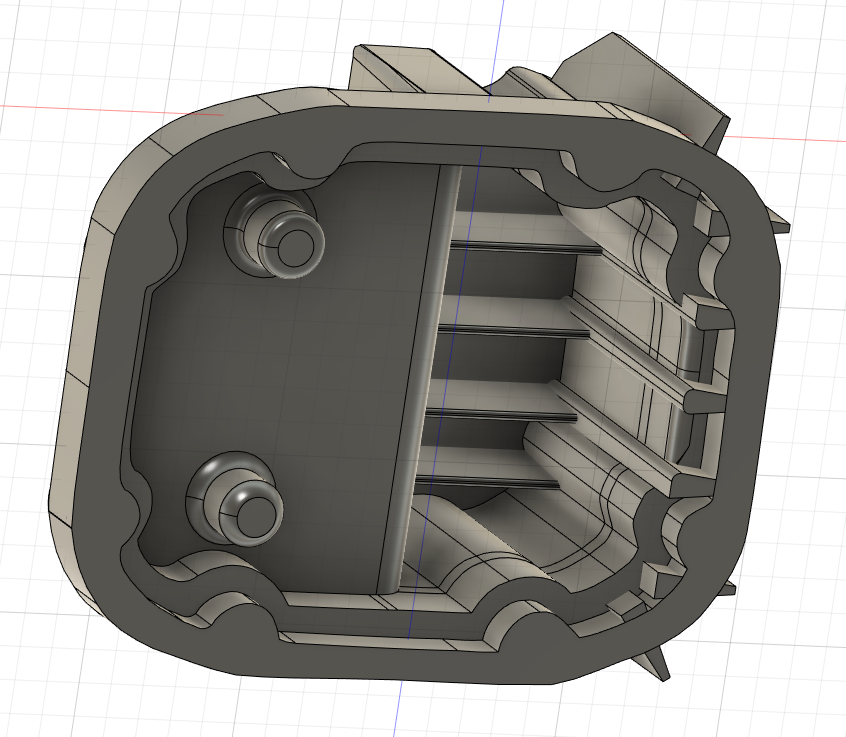

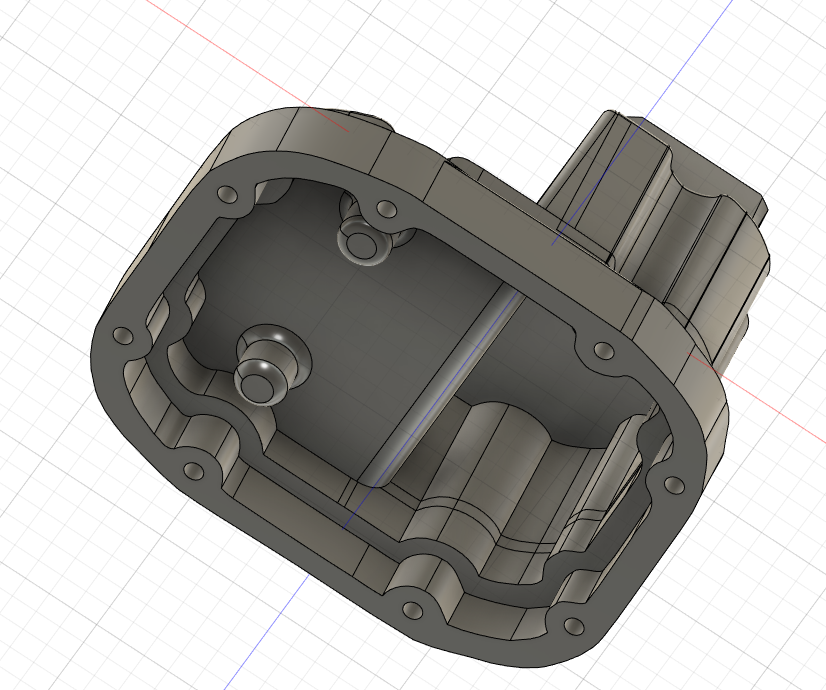

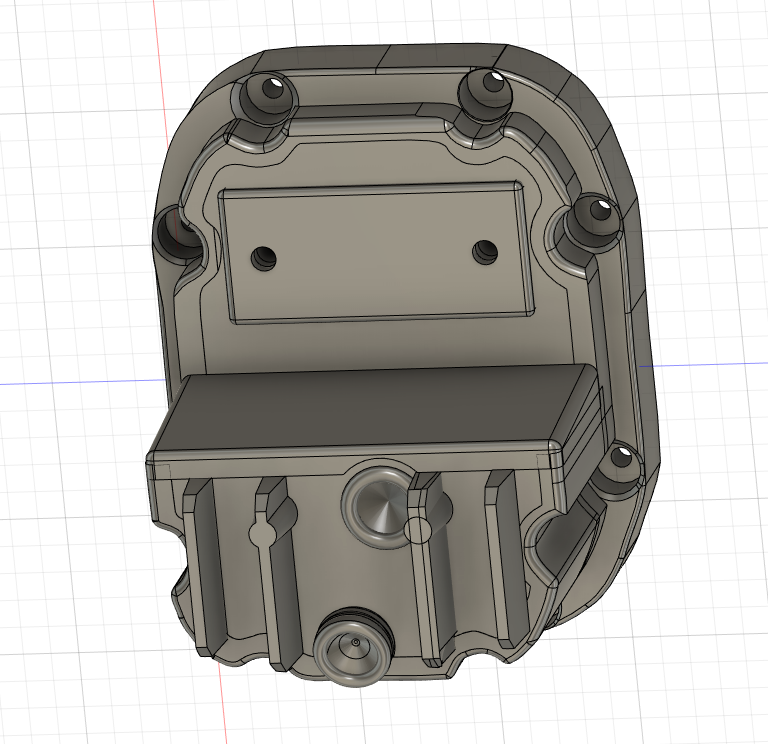

Thank you for all the input. My knowledge base for casting is at the low end as I’ve never had casting done for anything, but this is a chance for a new adventure of sorts. I’ve modified the design based on comments, and I was planning on printing a 3D test piece to send to the caster to review. I recall that he said to keep parts to ¼ inch or thicker and to have a draft as CO called it to make it easier to separate parts from the mold. I think that the concern might be that the separation of the 3D printed part from the sand to form the mold and not the separation of the cast part from the sand, but what do I know? Besides external fins, I’ve also added fins to the interior to promote heat transfer between the fluid and the aluminum although aluminum to air is likely the more important thermal transfer concern. The interior fins should also add strength to the bulbous oil reservoir. I was planning on doing all the drilling of the holes post casting. With all the points CO brought up, I think this part is not going to happen for a few months while I research the process a bit more and communicate with the caster.

-

Does an LSD need better cooling?

When I called in December they said they will be doing aluminum in 3-4 months so they are likely a very small, busy operation. I'm going to enlarge the entire structure using a percentage of around 6.5% to allow for shrinkage*. I guess if dimensions are critical, you don't use cast aluminum which is likely why you need shims when assembling a cast aluminum differential. *Every time I see the word shrinkage I think of that Seinfeld episode.

-

Does an LSD need better cooling?

My worries about the fins was that I don't know how thin I can make them. They are 4mm across the top. I was warned that they need to be tapered to allow them to release from the mold. I have a spot on two of the fins where I can attach screws to mount an air deflector to direct air flow from below the differential across the back. I don't know much about casting but my understanding is that the Cattail Foundary uses sand casting. They only do aluminum every few months so it might be a while for them to get to doing it. All they need is a 3d print that is scaled to account for shrinkage. https://www.lancasterfarming.com/country-life/antiques-and-history/cattail-s-customers-come-from-near-and-far/article_bfdbf807-69b1-5194-9fee-762e003d46dc.html Back to my original question, does the presence of an LSD heat up the differential more than an open differential? Should I increase gear lash slightly to account for the increase in temperature? I notice that my gear lash (pinion to ring gear) decreased when I installed the LSD so I had to do some shim adjustment.

-

Does an LSD need better cooling?

I'm getting back to installing an LSD in my R180 but I was concerned about the LSD heating up the differential during Auto-X. I drilled/tapped a hole in the fill plug for a temperature sensor but I also was looking into an alternate differential cover with extra volume and cooling fins. I located a family-run foundry operation that will do a one-off aluminum casting for $40 plus $3/pound so I designed one. Anyone want to comment on the design?

-

Quaife LSD Installation in R180 - With Questions About Installation Also

Yellow vs Prussian blue marking compound My local auto parts store only had Prussian blue. I tried it for marking my ring gear but it seemed to be difficult to observe a contact pattern. Would yellow of been a better choice?

-

My Z has a new stablemate

At the time I was too confused to be terrified. I had my seat reclined and I was covered with my winter coat as my son refused to turn up the heat. Then I heard "Dad, Dad... my steering isn't working". Luckily the turnpike was neither curvy or crowded and we still had a couple of degrees in either direction on the steering.

-

My Z has a new stablemate

My son just purchased a 2005 Lotus Elise. It needs some cosmetic work but is mechanically sound. Its currently stored under my 260Z that is waiting on its differential to be installed. We drove to Chicago from Cleveland to pick it up and had an eventful road trip. On the way there, my son's 2019 Veloster Type N's steering wheel locked while driving at 80 mph on the turnpike. He was able to inch the car to the berm, cycle the ignition off and on and that cleared the lock. We just found out this morning that there is a TSB that covers a slew of Hyundai models that addresses this concern so its sitting at the dealer waiting on a part. Please ignore my junk filled garage in the photo.

-

KAAZ R180 LSD fit problem

How many times have we all felt like an idiot when working on our cars? 😀 Did I ever mentioned how when I first purchased my Z I immediately changed the oil but didn't notice that the gasket from the old filter stuck to the engine so I had two gaskets. I drove around the block and wondered why there was a trail of oil leading out of my drive. Luckily a PO had installed an oversize oil pan so there was still some left.

-

Audio quality from rear speakers behind interior panels

If you move the sub woofer under the driver seat you can feel the music even if you cannot hear it over the exhaust.

-

KAAZ R180 LSD fit problem

I just got mine to fit. I didn't need to grind off nearly as much as InLine6 did on the gear side and on the other side, I just needed to grind a little off of two spots on the 1/2 shaft opening so that the LSD carrier could make the turn. Now it easily falls into place. I'm surprised that an LSD designed to fit a specific case will not fit unless you alter the case. Hopefully since I chickened out of replacing the pinion bearings, I won't have a shimming issue. I attached a shop drawing of the KAAZ DAN2020 LSD and I was wondering if it is smaller than the Quaife unit. Jeff

-

KAAZ R180 LSD fit problem

Thanks GK I'll give it a try.

-

KAAZ R180 LSD fit problem

I don't want to hijack the other thread on a R180 LSD installation. I have two photos attached on an LSD being installed. One from the internet from a Subaru that shows it just goes in nose first, is turned with two fingers, and slides into place. The other one is of my KAAZ LSD going in nose first and not moving beyond that position. The Subaru was replacing an LSD with another LSD while mine has never had an LSD. The ring gear almost clear the side of the housing. Are there any tips on what I need to do other than keep at it?

-

Gluing approach on 240z sign of glovebox

I like the door hinge. In 2020 I had to fit a new hinge in my glove box and used this because I didn't know Skillard made these: https://www.mcmaster.com/1588A742/

-

Quaife LSD Installation in R180 - With Questions About Installation Also

This is an aside for those installing an LSD in their R180. It came to my attention that R180 ring gears were provided in 110 and 115 mm IDs in the US. The KAAZ model DBN2020 LSD that I purchased was designed for the 115mm. I had to enlarge my 110 ring gear so it would fit on the KAAZ. It took me an hour to mount the ring gear perpendicular to the lathe axis and another hour to carve out about 5mm. The ring gear is incredibly hard steel. Lucky for me there was a knowledgeable machinist available to help me.

-

Quaife LSD Installation in R180 - With Questions About Installation Also

This is an amazing project I'm glad I didn't attempt. I have two potential avenues of assistance if you need either one. My fall back mechanic for my Z, Lanny Ritz in Kent, OH can handle just about any issue with a Nissan, except he doesn't do differentials. I can get you the contact information he ships his differentials to if you get into a real bind. If you need help cutting out a shim, I have access to a water jet. You would just have to ship me the stock.

-

Happy New Year 2024!

How many years until you can call them NOS (New Old Stock)?

-

Quaife LSD Installation in R180 - With Questions About Installation Also

Your machinist's comment about tolerances might explain why when I tinker around at a machine shop at the university, I'm forced to convert all my projects to inches from metric. This thread has convinced me NOT to pull out the pinion on my LSD upgrade. All this trouble just to get the right shim is not worth it.

-

Quaife LSD Installation in R180 - With Questions About Installation Also

You are a few weeks ahead of me. I couldn't find anything on the internet about rebuilding a R180 so I was using the instructions for a R200 at: Like you, he also used gear marking compound. I purchased a KAAS 1.5 LSD and it just shipped last night from RHDJapan.com (model DBN2020SQ). I'm reluctant to remove the pinion shaft because I'm not sure I can get the lash correct when I reinstall it with new bearings. I'm looking forward to how it goes with your build. Please keep us updated.

-

Replacement seat covers-QUALITY??

If you contract with an upholsterer, you can select just about any fabric you like. Or, if you are like me and have your heart set on a specific pattern, take this as an opportunity to learn upholstery. I'm doing that with leather so I can cover my dashboard.

-

Replacement seat covers-QUALITY??

I went with leather and I'm happy with that. Otherwise, I'd suggest finding an upholsterer to create a new cover.

-

R180 Gear Ratio

I think zKars is right. It's hard to say where the differential came from because the R180 was switched out with an R200 in the early 1980's but some time after that, it must of got switched back to an R180.

-

R180 Gear Ratio

I'm trying to determine the gear ratio on my R180. There is a number on the ring gear of ?? x 394 Does this mean 3.94:1 ? Should I just see how many turns of the differential input is required to make a full revolution of the ring gear? Can anyone assist in decoding this? Jeff