Everything posted by EuroDat

-

Sway bar end link bushings

The raised lip goes in the sway bar. See photo's. The lip is there to prevent the swaybar touching the metal bolt. Prevents meta, to metal rubbing noises and acceleratd wear on the bolt.

-

need help car starts but will turn off after a few secs

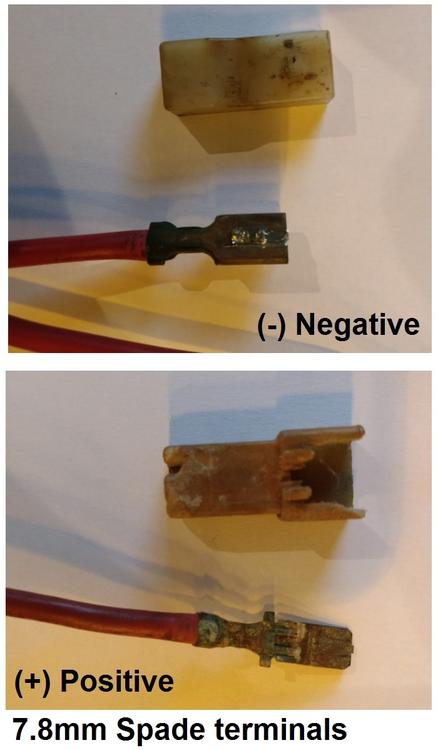

ok so to your questions 1. yes it is a 79 280zx distributor i dont know if its a D6K9 it dose have external HEI witch is the little box outside it right if so yes. What did you do to disconnect the external TIU. It could be causing issues with the HEI. Note: The 280ZX 79 – 80 used the D6K9-02 through to D6K9-10 distributor I think. Might be more versions. They are mostly the same, but some with slightly different advance curves and vacuum advance. The only thing important here is it’s a D6K9 series with build-in TIU. 2. yes no more ballast. 3. yes new coil it is a BWD coil it is a 12v not to sure on the amp number how would i check that?. 12 volt is the most important. If it’s a 3amp coil the HEI won’t go to current limiting. You will probably have problems running spark plug gaps of 0.040 to 0.044”. A gap 0.28 to 0.031” would be the better with a 3.0 amp coil/HEI combination. 4 & 5. i did check the wires didnt do a supper deep check but they seem good i will go over them again and clean and check for swollen parts for all three wires. Corrosion in the terminals is a big problem and can cause voltage drop in the ECU power supply. A lot of weird issues in the ECU because the ECU does’t like low voltage. See photo's of corroded terminals. 6. i have not installed one yet but i been meaning to will try and do it tomorrow. Install one. You need to know what your pressure is. 7. i do not know what a yoghurt cop test is but i did check all my lines and boots and they are pretty good boots look almost like new. A yoghurt cup test is a simple leak test you can do on the inlet manifold. Basically you remove the rubber hose between the AFM and the Throttle body. Block the hole in the throttle body with a “Yoghurt cup”. I use a plastic sheet over the open end and a Tye-rap to seal it off. After you have done that I remove the hose that goes to the AAR and blow into the manifold there (See photo for location). Even with your lungs you should feel pressure build up. My 77 holds pressure for about 15-20 seconds or more before its gone. If you (or someone helping you) hears air blowing out the exhaust, That is valve overlap and you will need to turn the engine a little to find a spot where there is no overlap. 8. i have i kinda have it wear it seems to run the best wen it decides to run Do you have a timing light to check it while you crank the engine? It should be around 10deg advance. 9. well my tach at first it did for less then a second but now i do not have the dash in my car and my harness is fairly clean no cuts That is the first you mentioned the dash is out of the car. and about the last owner no all he told me is that he swapped the engine ECU might be stock as the harness in and outside the car looks stock as well. Can you have a look on the ECU. You should see a number beginning with A11-xxx-xxx. Since we don’t know for certain what the PO did, you could have an ECU that doesn’t match your harness pin layout. There are a lot of different ECU’s out there and not all will work in your car. thanks for your help to all you guys it is very frustrating specially wen i had it running fine for less then an hour haha thank you guys a lot. You also mentioned the Transistor unit was on the ground and it sparked. Can you explain that in more detail. Things like when the key was in ON position. Or when cranking the engine it started sparking through the metal box to the chassis/floor of the car? That does not sound good at all. That could have damaged one of the fusible links in the engine bay in front of the battery. The ignition relay might be working and supplying power to the dropping resistors (inner fender next to the brake booster) and the injectors, but the ECU grounds them. Like Zed Head said. The CSV works on a different circuit in the ECU and doesn’t need anywhere as much current to work. It could work easily on a poor power and give you enough fuel to start the engine. A way to test this theory is to use starter fluid on the engine. When you start it, spray it into the intake and try to keep it running on that. That would confirm your injectors or pump are not doing their job.

-

need help car starts but will turn off after a few secs

Hi Jesus. You have been working on this problem for a while now and it must be very frustrating. It would frustrate me, and that is putting it mildly. I just read through this thread again and some things are not clear to me. Can you answer some questions to give us and idea were you are at. We have not seen the car, so we need your feedback to give any kind of usefull advice. 1. You changed the distributor to a 79 280ZX (D6K9) with built-in TIU. Are you still using the distributor with the external HEI module? 2. The ballast resistor is now bypassed. In our pm conversation. 3. Did you replace the coil with a 12 volt coil, one with 0.6 to 1.0amp specifications? 4. Did you check the ground wires at the battery? Wires to the body and to the ECU are not swollen and distorted. That is a sign of corrosion under the insulation. Check the connection for corrosion in the spade terminal plugs. 5. While you are at it. Check the fusable link spade terminals on the ECU positive wire. They corrode too and can cause voltage drop to the ECU. 6. Have you installed a fuel gauge to confirm the fuel pressure is ok? The fuel filter is NOT only one thing that can cuase presuure to fall away. 7. Did you a "yoghurt cop" test to confirm you don't have a really bad vacuum leak? 8. Have you tried turning the distributor while starting it, or rotating it back and forward and testing if it runs? Replacing the distributor, the timing could be way off. 9. Does the tacho work when it does run for a brief couple of seconds? Do you know what the PO has done? He changed the engine, but did he change anything else? ECU, wiring harness etc. Here is hoping you get it solve and up and running soon.

-

need help car starts but will turn off after a few secs

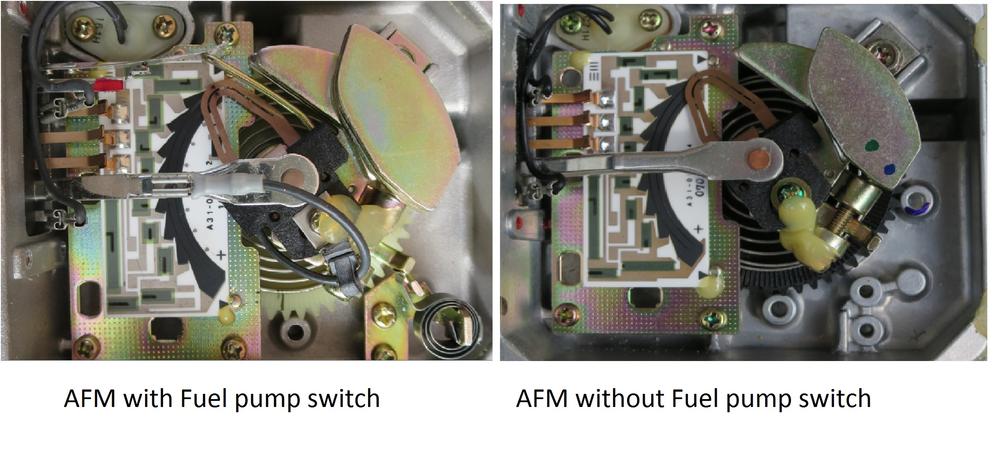

Yes, What do you mean by diconecting the AFM? If you mean disconecting the 7-Pin plug, then yes it will start, but it will never run more than a couple seconds because the fuel switch is in the AFM. The fuel pump is activated by the key contact when it is in start position and after that it is operated by the contacts in the afm. What was it doing before you disconectdd it. Would not fire at all or ?? Interesting adjustment method on the 76 model. It uses a screw on the counter weight like the 78 where the 77 has a tab in the housing. Not helping you any, but just interesting to note the small changes.

-

Front Lip Reproduction trial

I think they are Belgium. They are about half an hour from were I live in NL. They had a good forum for members. Don't know if it is stil active. I use a company here in NL called Formx for the silicane rubber.Smoothsil 950. It worked really well and lasts a long time before twaring. I always used a very light coat of release agent. http://www.formx.eu Nice instrctions and info on mold making here too.

-

Front Lip Reproduction trial

I would go for a silicone shore A 50 or 60. And one with a platinum catalyst instead of the tin catalyst variety. The tin catalyst silicone will work, but it feels oily and attracts dust and grime. Its not as durable as the platinum silicones. +1 on your supplier advice for sh. 80. The harder the better for wind resistance. Sh 80 will still be flexable. Have you looked at the website from Alumilite. They use to have some interesting how to videos. Good to get you thinking about how to go about it. https://www.alumilite.com

-

Front Lip Reproduction trial

Can't believe I missed this thread. Playing with PU rubber I can probably understand the challenges you are/will have in this project. Fun but challenging. The biggest job I have done was my 280Z turn signal lenses for the tail light. The harder the shore the better. If you can get 80 or harder, I would use it. Another suggestion, use shore 60 for your experimental phase. It flows much better and is forgivjng while you perfect your technique. The resin begins to set after 15 minutes or so and the harder the shore, the harder it is to work with. You will want a vacuum pump that will get close to absolute vacuum. 200mBarA will not be enough to get all the air out of 75 shore PU. The container for the resin needs to be 4 times larger than the resin you are using otherwise it will boil over. 1 Litre resin = 4 litre container and a vacuum container to suit. Lightly spray the mold with release agent. Don't overspray it, but make sure you don't miss any sections. PU really likes to stick to silicone.

-

Spark Plug, Compression, Gearing, and Power Feedback

No worries, its Friday. I agree with the tuneup. The engine has a 20% increase in capacity over the L24 so everything working right you should have a noticable increase in power.

-

Spark Plug, Compression, Gearing, and Power Feedback

Hardway is using a L28 N42 block in his 240Z, but still 2.9L shouldn't be a problem if the rest of the engine components are for a L28. That was my point on the E88. "E88 with stock cam" is not going to work as well as a N42 or even a N47 with the bigger inlet valve. Thats is assuming it's of a L26. The L24 had smaller inlet and exhaust valves. Not enough info on what has been done to the head.

-

Spark Plug, Compression, Gearing, and Power Feedback

One thing I do when making any "improvements" is record a simple baseline performace to compare later. Easy to do. Go for a drive and do an acceleration test in 3rd, 4th or 5th gear, depending on your final gearing. Start the test at around 1500rpm full throttle to the maximum rpm you are happy with. Record how many seconds it takes to get to 2000rpm, 2500rpm, 3000rpm etc. After your improvements are done do the test again and note the difference. A friend of mine put tripple webers on his Zed and it sounded great, but when we tested it it was actually slower up to 2500rpm. Took a dyno tech 4 hours rejetting, and then playing with the timing and cam timing to make a big difference.

-

Spark Plug, Compression, Gearing, and Power Feedback

An E88 73 head could be an early L26 or the last of the L24 where they started with the emmision chambers. The E88 up to around mid 72 are the most desirable of the E88. The E88 on the L26 had the larger exhaust valve and emmision chambers. Too many unknowns in the head to say if it is causing you grief. Do you have any info on what is done to the head?

-

Flywheel removal.

Probably the PO didn't tighten the bolts to the specified torque and they loosened over time. There is a reason for a certain tension on bolts. When the flywheel and crankshaft heat up, the bolts can expand and become a fraction longer. In this situation the flywheel can move and the bolts can loosen further over time. The tension Nissan specifies is calculated the prevent this from happening.

-

Flywheel removal.

Personally I would not use high strength loctite because it will require heat to release the bolts. All I do is clean all the threads, lightly oil the threads and use a tension wrench to tighten them to spec. Dry threads have more resistance and will not tighten down as far ss lightly oiled threads.

-

need help car starts but will turn off after a few secs

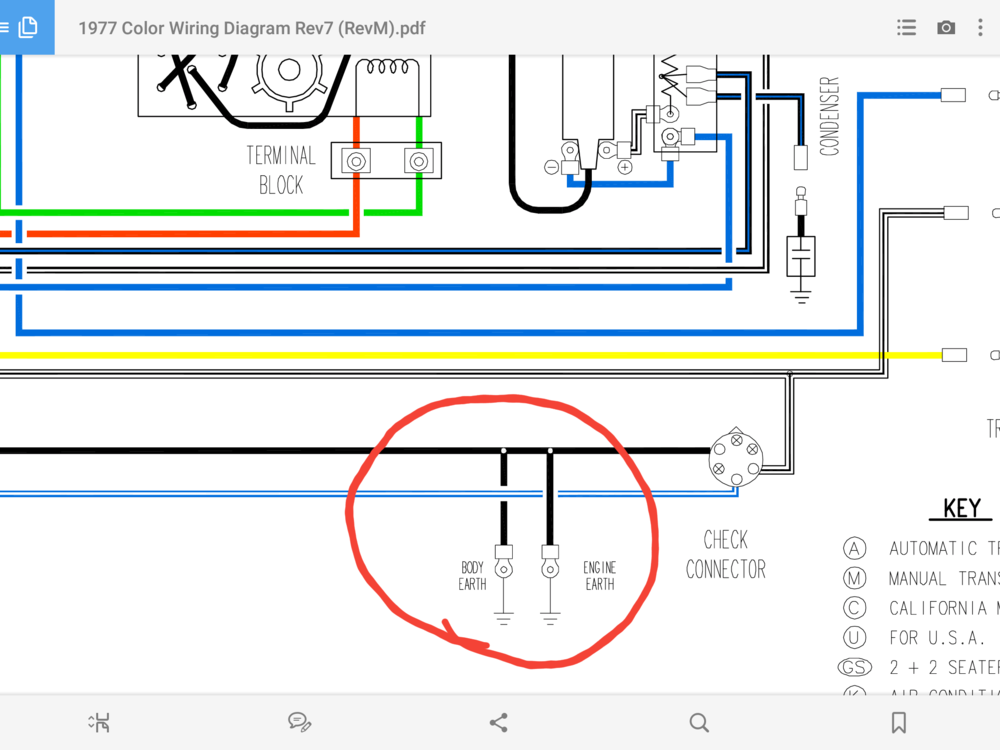

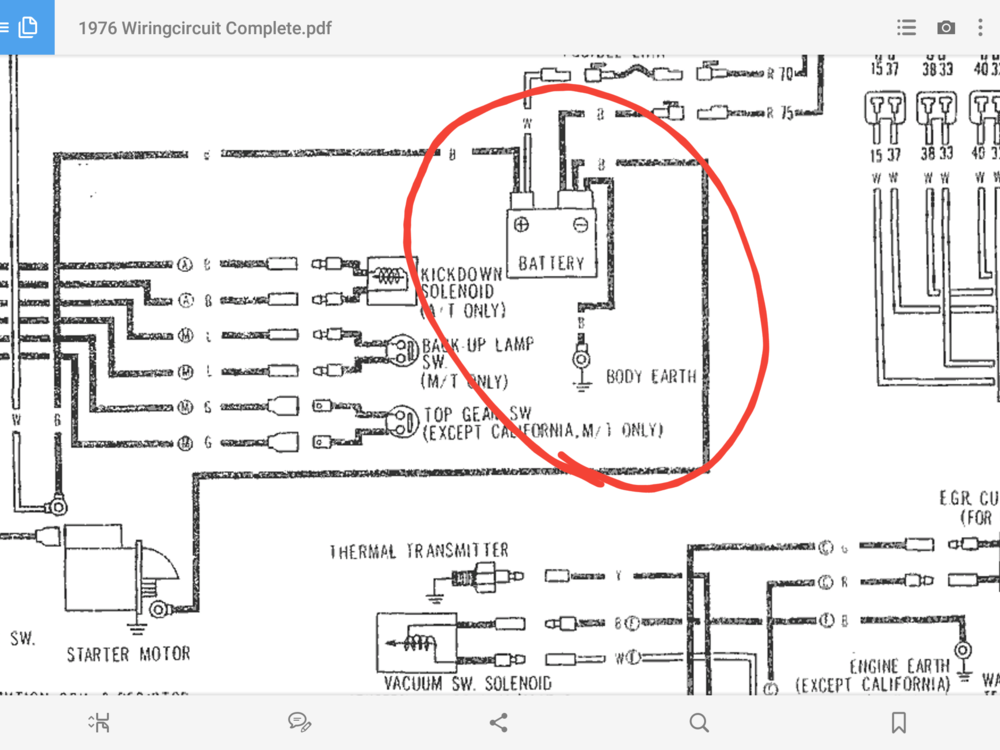

Jesus, When you check the earth wiring, check at the battery as well. The photo I posted is from a 5/77 model. Somewhere in 76 they changed from earthing the body to the battery to the style in the photo. Not sure which month they did it. Yours might be ok, just located at the battery. If that is the case, check the negative battery post for three cables, the large heavy duty cable for the starter, another cable with a connector (ECU ground) going over the firewall towards the brake booster and one going to the body just behind the battery. I made a couple of screenshots to show the difference. Chers

-

need help car starts but will turn off after a few secs

Godd work Siteunsen. I couldn't even find that one. I did find one where someone was asking about the yogut cup test. It might have something to do with the migrating from the old server to the new one.

-

need help car starts but will turn off after a few secs

Hi Jesus, We have been PMing over your HEI module swap and I missed this thread altogether. Your problem could be caused by a number of issues or even a combination. The AFM switch is a common cause. The AFM has a cap with silicone kit. You can gently cut the kit and remove the cap to check the switch. Check the switch adjustment by reaching in from the air filter side and moving the vane or turning it by the counter weight by hand. Check for vacuum leaks. There was a thread on here called the Yoghurt cup test, but I can find it anymore. Basically its just removing the hose between the AFM and the throttle body and blocking the hole with a yoghurt cup. The removing a hose so you can blow air into the manifold with your mouth and searching for leaks with soapy water. Fuel pressure and pump capacity are also things that can cause your problem. Buy a simple gauge and you can do some symple test to check the pressure and flow. A blocked filter can be so bad, that the car will idle, but the pressure will drop right off when you open the throttle and need more fuel. The fuel system has infact two filters, one in the pump inlet and the filter at front right side of the engine. See the instruction in the pdf. It is for checking leak down, but the flow test and basic pressure check while running engine is what you need. Check the earth terminal on the top of the inlet manifold. It is very important for the EFI. And check where it connects to the body on the side of the strut tower. Cheers Instruction - Fuel Pressure Test 280Z RevA.pdf

-

Gearing down with blue smoke and back firing

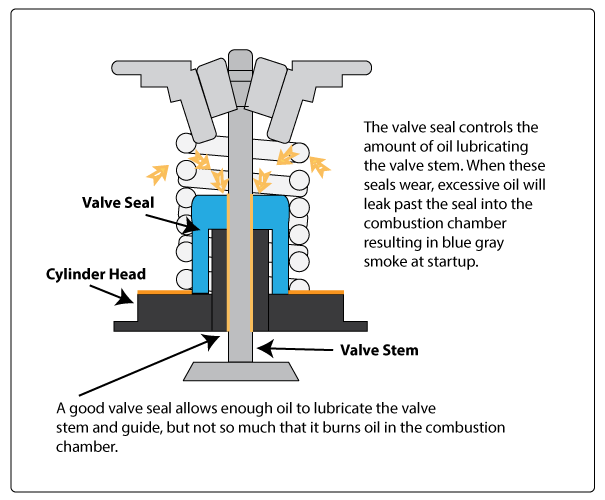

I agree with Mark. Valve seals are not that big a deal. You will get carbon buidup around the inlet vavle head (on the manifold side), people behind you may comment at the occasional smoke plume and it might use a little more oil than normal. Leaking valve stem seals won't leave you standing on the side of the road waiting for road side service.

-

Gearing down with blue smoke and back firing

Hi Jai. Yes, if you have enough revs and no throttle. There should be enough vacuum to pull in oil and not burn it. Then drive further a little harder than normal. Is it a good sign. The seals are not expensive and people use the ford units with succes. Getting them fitted could be costly or someone close by that is hangy with cars could do it.

-

Gearing down with blue smoke and back firing

Hi Jai, From your description, the first thing that comes to mind is valve stem seals. They are little rubber seals around the valve stems that limit the amount of oil passing through to the valve guide to a minimum. If the become old, they harden and break and allow oil to run down the stem and throught the valve guide to the inlet valve. The inlet valve is mostly under vacuum and causes the blue smoke problem after a period of coasting and the acceleration. A simple test would be to coast down a hill with no throttle and at the bottom of the hill a short burst of full throttle or hard acceleration. You should see a plume of grey blue smoke. That is a good indication. Why the test: When coasting, high vacuum pulls in more oil then normal, but a closed throttle doen't give it enough fuel air to burn the oil. When you give it full throttle, the fuel air mixture then burns the oil creating excessive smoke for some seconds. A compression test will tell you more about the overall condition of the engine. A bit hard to say if the putt putt sound was there before or not, since the muffler was changed, makes that hard to say with any certainty. And you mention the exhaust sound is more noticable with the new muffler. The smoke issue could be all some time, but it has now come to your attention due to the sounds from the new muffler. Goodluck with finding a solution Jai. Regadds Chas

-

Transistor Module swap *PLS HELP*

The 5 pin connector version E12-27 was used in the 78 model and doesn't have the dual pick-up function. You can use it, but you will have choose one pickup and forget the white wire. Have you done the simple checks to determine the tiu is your problem? You can try the tests at the end of this instruction. Its for the 77 model, but the tests will workonthe 76. Instruction - Fitting a 4-pin HEI module to 280Z 1977 RevD.pdf

- Transistor Module swap *PLS HELP*

- Transistor Module swap *PLS HELP*

-

1976 280Z Restoration Project

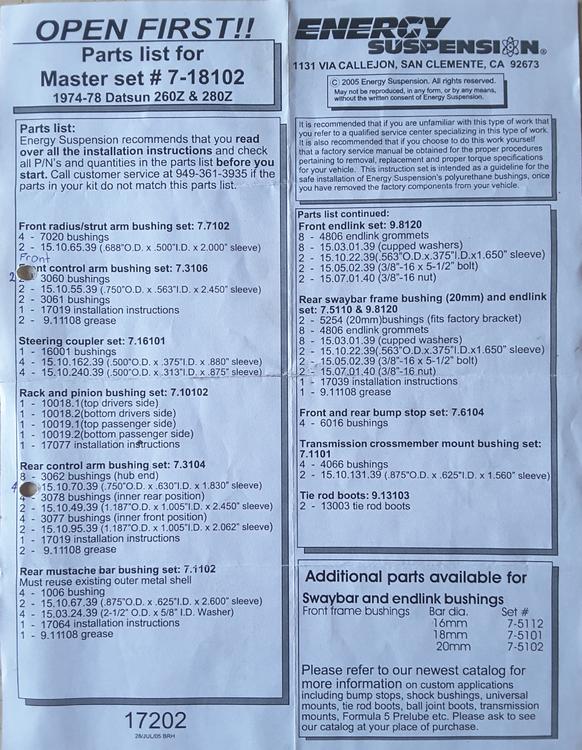

Not sure if this helps, but the kit I used was all in plastic bags with the part number on the bag. They were the correct bushes in the Master set #7-18102. That was back in 2012 and things change, including the way they package their product. It could be a simple issue of wrong part in the kit.

- 1976 280Z Restoration Project

- 1976 280Z Restoration Project