Everything posted by Captain Obvious

-

COVID-19

And lastly, two final thoughts on the whole matter... 1) Do not confuse wearing an AFDB on your head with wearing a colander on your head. Two completely different purposes. One holy, and one unholy (literally). 2) Neither the colander nor an AFDB will do anything to protect against covid, so GO GET YOUR VACCINE!!! Even if you don't think you need it for yourself, do it for all the other people you come into contact with. We're all in this together and if you don't get vaccinated, you're potentially the Petri dish for the virus to mutate. If you want to get back to normal, get your vaccine!!

-

COVID-19

Well that could explain a lot..... Haha!!

-

COVID-19

Oh you know I do. That looks like the chip pan on the lathe. You could probably form them into a AFDM (Aluminum Foil Deflector Mullet).

-

COVID-19

Hmmm... That's an interesting point. I've never carved one completely out of a chunk of solid aluminum. I wonder if that works any better. I'm thinking that the foil is pressed during production thereby compressing the anti-mind control properties closer together, but the billet is hot forged which allows the molecules to form a more regular crystalline structure which may help as well? Maybe we should test them both at a Zcon sometime. I wear one style and @siteunseen can wear the other. Whichever of us acts more out-of-control is obviously the subject of less mind control (duh).

-

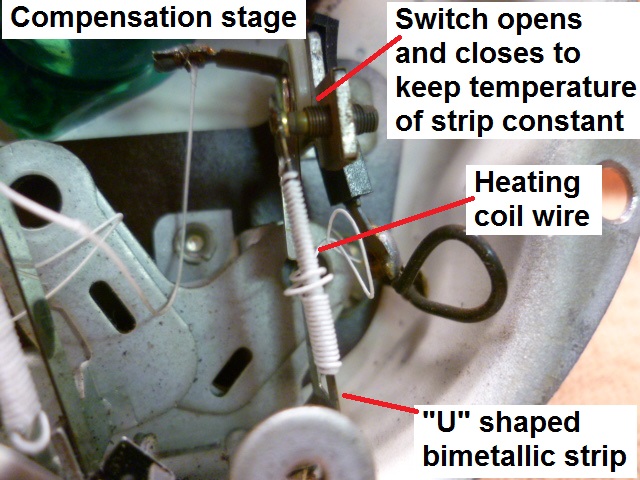

Fuel gauge issues - 73 240z

Yes, the regulator switch is similar to a set of points. It doesn't open and close as quickly, and it doesn't handle nearly as much current, but yeah... It's opened and closed an untold number of times over the past 50 years! So that pic I posted is from the front of a 280 gauge with the faceplate removed. On the 280, the faceplate for the fuel/volt is split down the middle and you can take either half off. Two screws and half the faceplate comes out. Here's a pic of the gauge with the plate intact. Take out the two small screws at the bottom and the "VOLT" faceplate comes off revealing the guts insde. Be careful and gentle and make sure you don't bend the needle. Don't know if the 240 is the same, but the 280 looks like this: If SteveJ works up a video, that would be fantastic.

- Fuel gauge issues - 73 240z

-

Fuel gauge issues - 73 240z

Excellent work. So I measured the loose fuel gauge I have here and I get about 50 Ohms. There are several possibilities to explain the difference... 1) You measured it wrong 2) I measured it wrong 3) They dramatically changed the design between your 73 and the later 280's (I think my test gauge is from 78) 4) Your voltage regulator switch is dirty and has way more resistance that it should Of all those possibilities, I consider #4 to be the most likely. Especially in light of your result backfeeding the gauge. So I'd try pulling a narrow strip of printer paper through the switch contacts and see what happens. This is a 280 gauge, but the switch should look something like this:

-

COVID-19

The question and debate about aluminum vs. tin is not new, and the answer is that the people who wear real tin (Sn) are loonies. From https://www.zapatopi.net/afdb/alternatives.html#TIN "In general, when people say "tin foil" they really mean aluminum foil. But what about tin (Sn)? Does it have the same anti-psychotronic properties as aluminum? Most experts agree that tin does have an effect but opinions are divided as to whether or not it is as good as aluminum. A small, but vocal, contingent even argues that tin is superior, but they are held by most to be the lunatic fringe of Foil Deflector Beanie science. I would advise people wishing to build a Deflector Beanie to stick with aluminum whenever possible since it is a proven technology." And more reading on the "The History and Anti-Psychotronic Properties of Tin" can be found here: https://www.zapatopi.net/afdb/tin.html

-

COVID-19

Oh, and I forgot to mention that it's actually recommended that you make your own aluminum foil deflector beanie (tin foil hat) and do NOT purchase one of the commercial pre-made versions. Since Zed Head mentioned that you should trust no one, it reminded me that precaution pertains to your AFDB as well. From: https://www.zapatopi.net/afdb/ "BEWARE OF COMMERCIAL AFDBS: Since you should trust no one, always construct your AFDB yourself to avoid the risk of subversion and mental enslavement. Sometimes, AFDBs will be sold on places like eBay. Do not purchase these pre-made AFDBs, even if the seller seems trustworthy. They may contain backdoors, pinholes, integrated psychotronic circuitry or other methods that actually promote mind control."

-

COVID-19

Will do!! Thanks!!

-

COVID-19

I've been an X-files fan from day one and have seen every episode more than once. I'm a big fan. But it's fiction!! Vault in the mountains where there are DNA records from everyone taken when they were given the smallpox vaccine. Alien technology vaccines. Silicon chips inside her head gets set to overload... "Oh yeah? How can you be so sure???" LOL.

-

COVID-19

Good! So your Moderna is holding steady!! I can feel the virus ricocheting off me. Pew! Pew! Pew!

-

COVID-19

I've been making my own for decades: https://www.zapatopi.net/afdb/afdbdiagram.pdf But I never looked this good:

-

COVID-19

Not sure that's going to work. The virus hits older folks harder than younger folks and the older folks have already had their kids. I'm no expert on the subject, but it seems to me that you don't change the gene pool by plucking out the folks who are no longer contributing to it.

-

COVID-19

I got my second yesterday. On the drive back home I could hear Bill Gates in my head every time I drove past a cell tower. It's awesome. Anyone know how long do you have to wait before the tracking device is activated? Is there anything I need to do, or is it activated remotely by someone else?

-

COVID-19

Site... So what's the verdict? Are you out there?

-

Old vs New SU's

I think it comes down to the authenticity of the build. With the slope of the prices for the very early cars, my leaning would be to put on something as authentic as possible. In other words... A rebuilt set of original four screws round tops. My question would be... Even within the four screw carbs used 69-71, there were some subtle changes over the years. I don't have a good handle on those changes, but hopefully someone here does. As a side note... I've got a pair of four screw round tops here that I think might be from a very early car. I think they're from that supposedly "completely original" BAT car that didn't sell because it had the wrong carbs on it.

-

[2021] What Did You Do To/with Your Z Today?

Well that all depends on the thickness of the mounting flange on the wheel itself as compared to the length of the lug nut shank. You never want the lug nuts to bottom out against the rotor. All that matters is that there is still some thread left once the lug nut bottoms out against the wheel and pinches the wheel against the rotor.

-

Prop shaft and half shaft phasing

Haha!! I don't know that!!

-

1977 280z EFI Nightmare

Now go away, or I shall taunt you a second time! Injectors leaking air is a big deal. Take care of that and we'll see what happens next.

-

1977 280z EFI Nightmare

Good progress. One layer at a time. I wouldn't worry too much about the AFM numbers right now. I've seen a couple anomalous readings from AFM's that worked great on the car. Might not be a problem there. I gotta admit though that with so much going on a the same time that I'm getting a little lost on what you're working on... Is there one test that is giving you trouble that you need help with? Pick one and work through it? Then move on to the next?

-

Prop shaft and half shaft phasing

"Well you have to know these things when you're a king, you know."

-

1977 280z EFI Nightmare

What he said, and you're right. One of those big red wires goes to the positive battery terminal, and the other goes to the negative. If you're looking for confirmation about which one goes where, the one that has low resistance to the ECU ground pins (5, 16, 17, 34, 35) should be connected to the battery negative. And the other one should be connected to the battery positive. So you guessed right before, or the car wouldn't run (and you would have probably fried your ECU), but just to double check, I'd measure some resistances. Also note that the big red wire that goes to the battery positive is supposed to have a fusible link on it. Yours probably turned to dust some years ago.

-

Prop shaft and half shaft phasing

LOL. What is your name? What is your quest? What is the force generated by a 1oz out of balance driveshaft?

-

Fuel gauge issues - 73 240z

G;ad to help. I wish I had some way to move forward without having to pull the gauge out, I do have one idea though... If you can disconnect the gauge from the harness and measure the resistance between the pins on the gauge that go to 1) the power input and 2) the output to the sender unit. I believe the two colors in question are yellow/red and the yellow wires. Not on the harness side, but on the gauge side with the gauge unplugged. That resistance should be an additive total of the internal regulator switch plus the resistance of heating coil #2. If you can tell me that number, I can measure the resistance of heating coil #2 on a different gauge here at my place. No guarantee they are identical, but they should be in the same ballpark. Then using that info, we can determine the resistance of your switch. It should be very low resistance, and my theory is that yours will not be very low. Just one more thing to look at for now that might be easier than pulling the gauge out?