Everything posted by Captain Obvious

- 240z - fabbing new front rails

-

Just bought my first Z car (240), drinking from the firehose

Yup. That'll do it. ^^ On a side note, I think the whole idea of running the primary ignition current into the passenger area and to the tach is a bad idea. I guess at the time that was the best they could come up with. They didn't ask me though.

-

Just bought my first Z car (240), drinking from the firehose

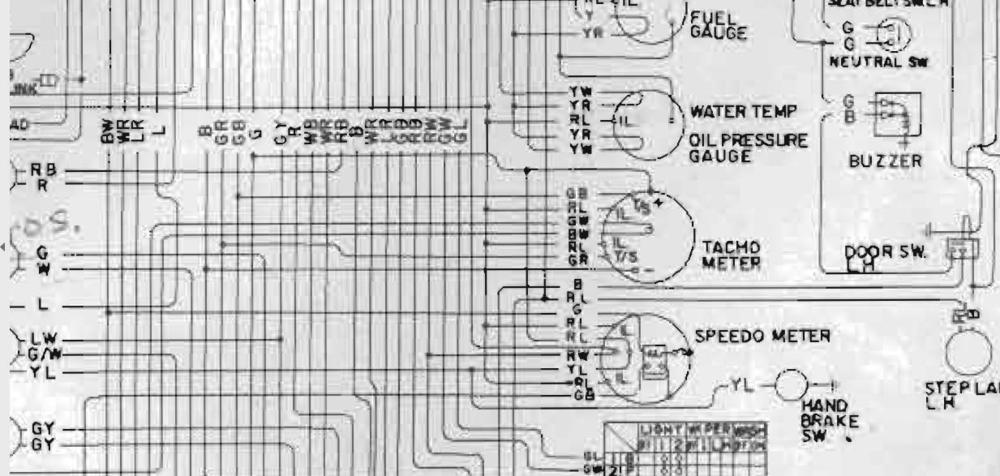

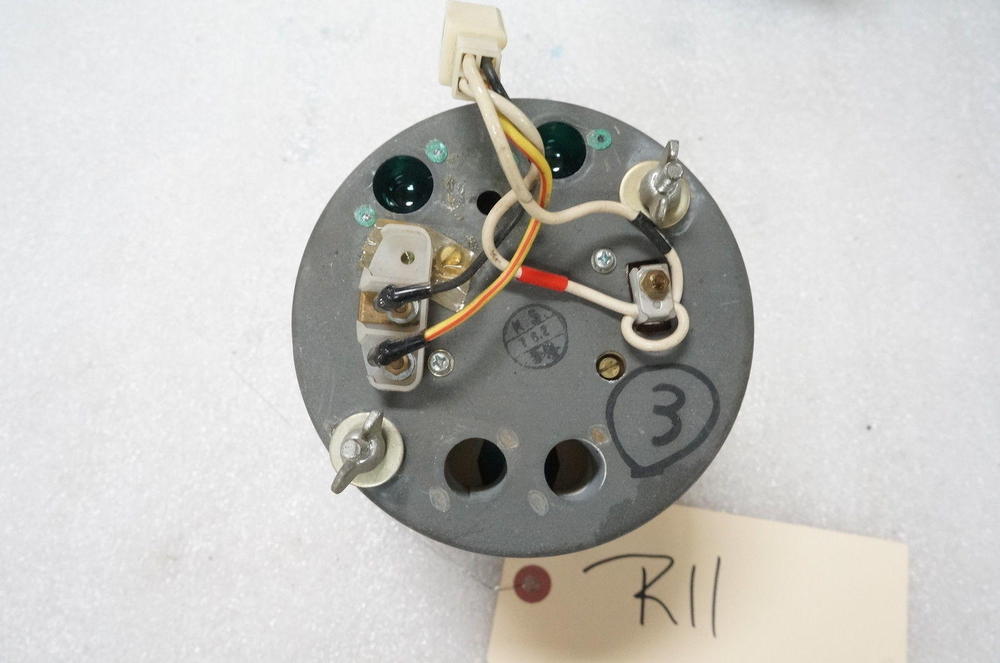

This is how the wiring diagram looks for 73 in the tach area. The two ignition connections (from the ballast resistor and then back out to the tach) are the GW and BW wires. On the back of the tach (on the tach;'s side of the connector) those colors are the white with the red and black tape stripes): So since they don't show the stub-off connectors between the gauges and the dash harness, (or any of the colors involved) it's hard to know for sure, but unless they pulled the ground signal through the metal tach case itself, then they ran four wires through the connector in that stub harness. However, as previously mentioned, I've never been deep into anything earlier than 74, so I would obviously defer to someone who has!

-

Just bought my first Z car (240), drinking from the firehose

That said, however, I've not owned an early one either. I'm going off pics and documentation. Like that can never be wrong... By the time they got to anything I ever delved deep into, they had switched over to the newer voltage sensing tach. I believe that was 74.

-

Just bought my first Z car (240), drinking from the firehose

Because on the early years they run the primary side of the ignition coil signal through the tach to provide pulses. That's the looped wire on the back of the "current sensing" tach. Now, it would be easy to bypass that and get the ignition to work without the tach, but if everything is wired according to stock, it shouldn't run without a tach installed:

-

Just bought my first Z car (240), drinking from the firehose

Yes, that is to be expected for the early years.

-

Parts for Sale: Nautical Paraphernalia

Wow... That's tough to resist. I'm resisting so far, but it's tough.

-

Ignition/Door key question

The little door doesn't seal perfect. So, even if you had one, it's not like you won't be getting water in there. I mean, the less water the better, but even if the door flappy does work, it's still going to leak some. Good luck moving forward and hoping it works out easy!

-

ZCON 2020 Hotel Impact?

I don't remember the minute details... Clearly from your highly detailed recollection of the other place, that's what I had you for. Something about the two guys were competing in the annual BBQ competition and were thinking they might win? Placed high previous year and thought they might take first place that year? They didn't want to recommend any Q from any of their competitors. They were not in the restaurant biz... One was a lawyer and the other was an a software guy or something? I bet they opened a BBQ joint after we met them. Any of that ringing any bells? Oh yeah, and their female companions were attractive. That's probably why you don't remember shitte.

-

Am I sporting a vac leak?

No trouble on the air cleaner info. Regina the 3rd will see it eventually and speak up. He's a lurker. Says he's "busy" or some crap like that. I'll bug him again @GGRIII . Nice. They won't like getting crushed, but still probably thinner than the foam. The real trick would be to chuck up the dome or body in a lathe and cut an O-ring groove.

-

Chg and brake light

The results look promising but keep an eye on it for a while. Haha!! Nice! Just keep an eye on everything!

-

Sunvisor refresh

Easy if you the have hands of a surgeon.

-

Ignition/Door key question

Yes, it's supposed to have a little spring loaded door over the hole, but most of them have fallen apart over the years. The springs rust and it falls apart. If you're lucky, the door and pin is still there but has just fallen open (always open) so you can't see it. In other words, it's in there, but off to the side. The little rusty nub is what's left of the door spring:

-

Am I sporting a vac leak?

That's not controversial to me at all. I completely agree 100%!! I'll check on those round air cleaner filter gizmos for you... Tagging @GGRIII . That's his car and he bought the air cleaners. I don't know where he got them, but I remember something about "cheap clones of the expensive ones". Hopefully he come in and shed some light. And hopefully they might be cheaper on your end of the pond as well.

-

Ignition/Door key question

So the glove box uses the same key as the doors? If that's the case, then I would agree that it sounds like the ignition lock was replaced. Not unusual at all. The hatch though... Seems a little unusual for the hatch to be replaced before the doors are. Maybe the hatch lock DOES use the same key as the doors and glove box. Maybe it's just all frozen corroded up inside. Taking the hatch lock out is not complicated, and after it's out of the car, taking the hatch lock apart is not difficult. It's probably one of the easiest. I'd take it out, clean it up, and see what it looks like inside. Failing that, a locksmith would make short work of the problem.

-

Am I sporting a vac leak?

Haha!! Excellent! Then I've accomplished my mission! So you could try a bead of silicone once you're sure you've got everything else dialed in and hopefully won't have to be taking the domes off again every other day. More hidden than the foam. Just as long as there isn't some other second order effect from the foam thickness that makes a problem come back. In any event, it's just great to hear it's running so well and I'm happy for you! I think that turbo-esque whistle is the air blowing across the holes in the bottoms of the pistons. Like blowing across the opening at the top of a bottle, or a flute. I had never noticed it until the original air cleaner was replaced with smaller individual ones on each carb. I think the large mass of the original air cleaner housing and the fact that the stock input snout pointed forward towards the radiator muffled the whistle. And good work with the FBTT!

-

ZCON 2020 Hotel Impact?

Wow. I'm impressed! Mind like a steel trap! Yes, he's the guy who gave us drink tokens. I was just happy he didn't call the cops on us! I bet he locked that door after we left! Haha!! The planks hold "flights", or "tasting flights". And yes, I remember that map. Showed it to her and she's like "Wait... The only thing on here is directions to beer?" You remember at one of the other stops on our tour... The two guys who were reluctant to give us a recommendation for BBQ? You remember the detail behind that?

-

Ignition/Door key question

Have you checked the glove box lock? In my limited experience, I've found that the glove boxes get the least amount of use and are usually the original key pattern for the vehicle. You may find that neither the ignition key or door key work in the glove box. That would be an indication that both the door and ignition locks have been replaced, and if that's the case, I bet the glove box and hatch share a common key (that you don't have). And not that it's a big deal, but locking the hatch doesn't make it impossible to press down. The button still presses in fine, but it misses the internal target linkage.

-

Chg and brake light

Hope that's the end of it! Send some of that heat our way please? We're running about 20 degrees below normal and I'm ready for some warmer weather. I'll be sure to send the heat back west to you before July so you don't miss out.

-

Am I sporting a vac leak?

Right. Sorry. I got hung up on your alignment issue (see what I did there?) and incorrectly translated that to a potential altitude change as well. Thanks for the nudge back to reality. I'll go back and cross that out. I've messed with flat tops more than the round tops, and from what I've seen, the machining quality got better. The precision machined sealing surfaces on the flat tops are pretty good. The bead of silicone I used was on an early set of four screw round tops. I've not had to do that on the flats. So how did you determine the surfaces were off? Lay it on a flat-ish surface and you can actually see gaps? As for the whistle, I would suggest it's perfectly normal. I believe that's air rushing past your venture and you should learn to love it. I traveled to Zcon last year in a flat top powered 260 with small aftermarket air filters, and when you punched it, that whistle was very pronounced. Sounded like a turbo spooling up. And the car felt like it too! Just think of it as your round top turbo!

-

Am I sporting a vac leak?

I've had a situation or two when I wasn't confident in the seal between the dome and the base. I just used a small bead of silicone sealant at the base of the dome. Worked great without changing much else about the mounting. So with the thickness of that foam, I'm wondering if it was a seal issue, or did the thickness of the gasket change your needle station positioning (On edit, forget this. This is not the case.) ? In other words, I'm not sure I know what it was that caused the improvement.

-

ZCON 2020 Hotel Impact?

Yeah, I gotta admit... It wasn't as classy, but it sure blended in. It's like my daily driver... I want it to be invisible. You remember that one shaky looking neighborhood when we ended up startling the guy in the brewery? Him, clearly startled - "Woah! Uhhh... Can I help you?" Us, being a tasting flight up already - "We we're looking for beer." Him (thankfully) amused - "Uhhh, OK. We got lots of that, but we don't sell it here." Hahaha!!! We could have easily ended up in a cell for that one! I think the only thing that saved us was your trustworthy face!

-

Quarter window trim panel

@Dferr17 So where were they listed? On ebay? I think those panels are for 76 only.

- 1976 280Z Restoration Project

-

Chg and brake light

Well most of that behavior is completely normal. The alternator output can (will) drop if the RPM's get too low. And if the alternator output drops far enough, the warning lights are supposed to come on. There are two things that concern me a little though, and that's why I was suggesting keeping an eye on things. 1) The alternator output might be dropping off at an RPM that's higher than normal which may be a sign that the alternator may be having some sort of internal problem. I don't know what the specs are, but on my car with an internally regulated alternator, my alternator output seems to be able to keep up easily at 700 RPM idle, even with the headlights and blower motor on. In other words, even with the headlights and blower motor on, I can let my RPMS drop to idle (700 RPM) and my warning lights don't come on. Might be a warning sign that yours do 2) The other thing that concerns me is the "latching" of either the VOLTS or BRAKE lights. Even if the alternator output does drop off at low RPM's, both those lights should go back out when you rev the engine. Every time. So if one or the other of those lights ever "latch" on, it might be another sign of impending doom for your current alternator. Makes me wonder if your brushes are worn to a nub and are making intermittent contact. Or your internal regulator may be failing. In my experience, things like this are warning signs that something is brewing. Might not be critical. Yet. But something's going on...