Everything posted by Patcon

-

3.5 L tt ecoboost swap

That's quick. Should be lots of fun...

-

Stroker 3.1

Is that a cometics head gasket? Does that first cam journal look rough or that just my eyes?

- [SOLD] 75 280Z For Sale

-

'75 280z - Head temp sensor question

The E88 also looks like it might have been cut. The casting numbers are pretty close to the edge. Some measurements would be in order there too. Also are the cam towers shimmed on that head?

-

Another unfinished project for sale in WA

Solve??? You mean start don't you...

- 510 Su's

-

The official "Post pictures of your wheels" thread

That's a pretty well executed convertible

-

3.5 L tt ecoboost swap

I bet that makes a Miata really fast!

- 1976 280Z Restoration Project

-

Z31 N/A RB project

I thought you might be running pretty aggressive rates based on the other aspects of the build. I also considered increased camber to get inside but I really don't like that solution for a number of reasons. Having the roller around definitely helps...

-

Z31 N/A RB project

It's gonna have to be awful stiff not to rub the tire. Doesn't look like they would be easy to roll either because of the way the fender is made. Might look sharp if some all metal flairs could be made that basically shift the wide flat wheel arch out an 1" or so. Some one good with an english wheel could probably roll them out...

-

'72 $3,000

Cliff! That's bad...

-

SUs and pumps

I have found that the fuel pump valves in the pump can stick and prevent the pump from pumping

-

Intake manifold paint removal

Some paint stripper and some carb cleaner and it might clean up. Carb cleaner will take off most un-catalysed paints. Bead blast after that, if you can, and pretend it never happened...

- 510 Su's

- 510 Su's

-

510 Su's

Yeah I have noticed ramflo's aren't as common but I like the look. I just don't know which style is correct for the 38mm carbs. One of the problems with looping the hose is the hard line was too long to connect to manifold, so I cut it back before I replated it. So that tee is now gone. I guess the real question is do I need that flow out from under the thermostat into this line?

- Stroker 3.1

-

Caswell Plating

I ran some plating last weekend and I ran it at a lower temp. Got pretty good results. Not conclusive... This is a run coming out of the plating tank. Really nice chrome-like results. Might be hard to see in the pics I also tried a little experiment. Sometimes tubes have some corrosion on them that makes them rough and thin. So I broke out the torch and some silver solder This is built up. The end was not wanting to take solder Zinced Overall a good weekend in the shop...

- 510 Su's

-

510 Su's

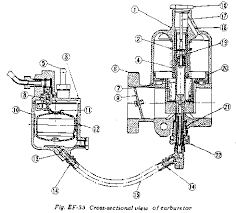

One of the needles is new from Ztherapy. The other is unknown... might should have bought two... I have another question, there is no port for the vacuum advance. Can I use another port off the manifold? In other words, is there anything special about where that port exits the front carb. The is no booster on Cody's car so I could use that port for vacuum advance and still use the center port for the PCV valve... Also there were a number of water ports near the carbs. Best I could tell water flow was from the head into the manifold then towards the front. The port out of the thermostat housing and the 90 degree tee out of the straight line were tied together with a hose and the other went to the old carb. For now I plugged the thermostat hole and connected the su manifolds to the line that runs around the front of the head. Should I do it differently?

-

1971 HLS30-14938 "Lily" build

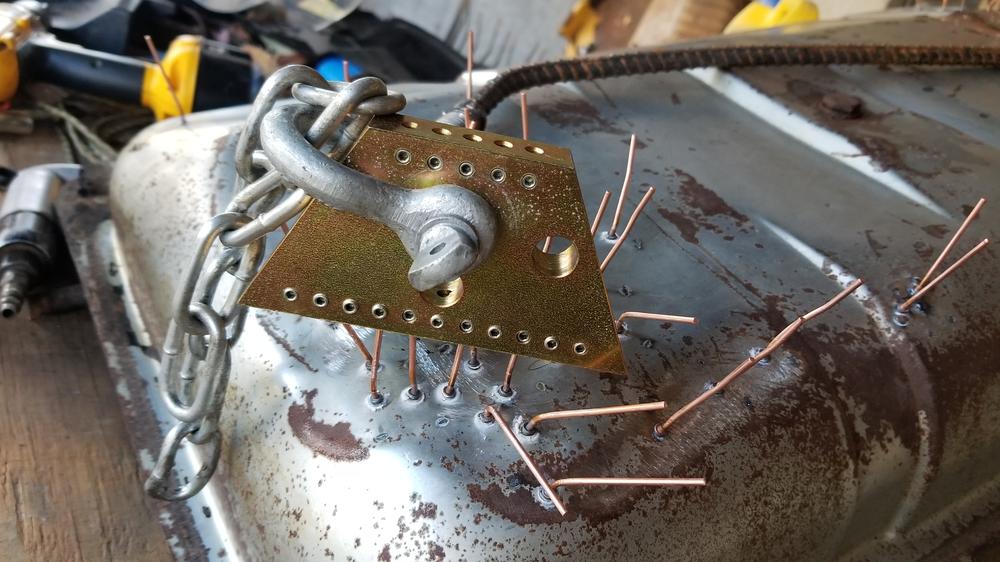

Ok, so I worked on one of the other tanks I have. This is a 240z tank. there is an amazing difference in weight between the 240z and the 280z tank. The 240z tank is maybe half the weight and noticeably thinner. A little aircraft stripper... Great stuff but don't get it on you!! Several large dents on the bottom A few studs going on This tool is really cool. It was $100-120 but when trying to pull larger dents works well. When you pull too hard on a single stud you can get a raised dimple or even tear the stud off. When you get 4 or 5 studs on you can really pull on them with out the raised areas We were banging on this with a 16# or 20# slide hammer. Had to stand over it on the table to do it. I took a piece of rebar and tried to make an extended dolly. It helps some but was hard to position and keep pressure on. If the holes into the tank were only slightly larger I could get my hand in there. This is sort of where I stopped. Not perfect but I will probably skim a few of these areas to satisfy my OCD then shoot some black on it This is a 100+ studs later...

- 510 Su's

- 510 Su's

- 510 Su's

Subscriber

Subscriber