Everything posted by Patcon

-

1971 HLS30-14938 "Lily" build

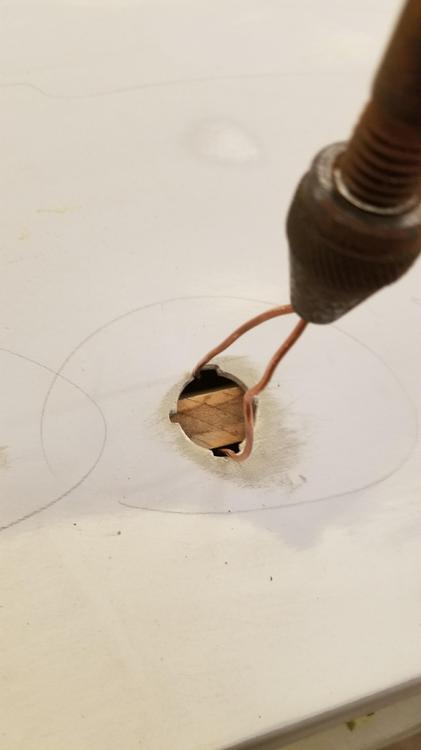

So I think I made progress on the hatch. I rigged up a slide hammer with a wire loop . I had Cody hold the hatch down while I did the hammering. I did some shrinking with the shrinking disc and I over did it. I ended up with divots and had to dolly them back up some Blocked it all down again. The circled spots are low now. I also used the same technique to lift the vent areas on the hatch. It's pretty thin now. It also looks like the lock will work now. I now have to do some filling and reprime the hatch and block it again with guide coat.

-

Misfiring while cruising

Do they still foul at idle?

-

HLS30-00456 Up for Auction on eBay

What a mess! It's already $5,300 reserve not met Every panel on that car will need work. Cowl is rotten, frame rails, floors, evidently has a sunroof, so roof panel, quarters, everything. At this point you're buying data plates and a minimal amount of metal. I hope it gets saved but I can't see paying that kind of money for this car. Although if it ends up at 100k in 5-10 years I guess that changes the calculus. Still, you better have a good welder and 50#'s of MIG wire

- My 240z project

-

1978 280z starting help

If it wont start with ether then it is either spark or a valve/intake issue. Have you checked compression? If the compression is good, then the spark is suspect

-

Cody's Goon

I think I want to avoid using a rust converter because of the possibility of Nitrogen embrittlement. I am hoping if I get it fairly clean I can lightly grease the surfaces to prevent future rusting. I think I will still probably open the cases up to check the oil gutter, the bearings and make sure the dogs look ok. I would prefer to not go further than that.

-

Where to go with this rusthole

I have never tried oiling bare metal. It makes me nervous. I try to avoid touching bare metal or body work with my hands to prevent adding oils to the surface. I just have concerns about being able to get all the oil back off the panels.

-

Cody's Goon

I might have to go that way, but I would prefer not to break the tranny down that far. I may try a rotary wire brush first to see how it cleans up. I think the splines will clean up. The snout that goes into the pilot bushing might have some pitting though. I think there is a needle roller pilot bearing available. I wonder if that would be a better choice if there is some pitting on the input shaft nose?

-

Datsun-240z Vs Fairlady-z432

Yeah, I liked that stand too. I also like the double staked nut. It looks like he added a set screw to the nut. Staked the edge of the nut and then staked the set screw as extra insurance. That's what experience will do for you.

-

To repair or buy new frame rails?

Be sure and make note of the roof joint thread I started, and follow John's advise on high to install the rails properly. More weld is not always better!

-

Cody's Goon

We have a new project on the table. We wanted to have a 5 speed in his car before Zcon but we ran out of time. So we have sourced a transmission. It was pretty cheap but the input and output shafts have some rust on them from sitting in the salvage yard This car didn't have a motor in it. So it was exposed. I plan on trying to clean this up. We'll see The tranny goes through all the gears and turns smoothly but had very little fluid in it. It may have leaked out the rear because there was no drive shaft under the car. The plan it to open up the case and look it over and try to clean up the input shaft. The output is pretty greasy and looks a lot better than this end. I am working on figuring out how to disassemble the two cases. We also had to convince the fill plug to come out. What a pain! It was already chewed up where some one else had tried to get it out. So we started with some specialty vise grips, nope Then we moved on to a large set of channel locks, nope Then we tried a pipe wrench with a cheater. Can get the right access for the wrench, nope. Then I reground the flats onto the plug. tried a 15mm with a cheater pipe, nope. So we moved onto the welder. I took a large nut and welded it to the end of the plug. The welds didn't penetrate and the nut turned right off. So I got a large bolt. Turned up the heat and tried again Then we got out the impact I win!!! Now I will probably have to source a new fill plug. If I can't get the input shaft splines clean. The input shaft available new?

-

L28 TDC questions

The engine aught to turn fairly smoothly with the plugs out. If it has been a while since it ran, there might be some rust scale in the bores. It is easier to turn from the crank bolt.

-

Cheaper would be a deal. 8^)

That car has been up for a few months now. It would need to be a lot cheaper for me to give a second look.

- [SOLD] 1971 240Z Original Restoration, 918 Orange - BAT

- [SOLD] 1971 240Z Original Restoration, 918 Orange - BAT

-

To repair or buy new frame rails?

Post up some pictures to make it clearer where you are working

-

Where to go with this rusthole

I have used "After blast" from Eastwood on clean metal. It has acid in it so it converts the rust and seems to keep it away unless it gets wet with condensation. Ospho would work too

-

Pan Shaping // Cutting Approach

Yes, get the shield gas if you can. Should be an Argon / CO2 blend I believe. Much cleaner welds

-

1971 HLS30-14938 "Lily" build

Thanks for the feed back.

-

Home Built Z 'Full video build'

Very carefully! I thought the same thing!

-

1976 280Z Restoration Project

You might want to pretreat the few little rust spots with phosphoric. I would do some research first though. I have seen some info that suggest some epoxies don't like to go over acid treated panels very well. I haven't had any issues with adhesion but some people have evidently had the epoxy come off in big pieces. If you do acid treat the rust spots, which is what I would do, especially after the paint failures on Cody's goon. I would go back after converting and sand the panel really well and shoot epoxy right afterwards. That would remove any excess acid residue and get you down to good metal and good iron phosphate

-

1971 HLS30-14938 "Lily" build

That's a good thought. I will look at the lock set. I am not sure there is enough metal there to make the slot wider. That's a good idea though. No, on the bottle jack, but I own a porta-power. I have a small puck jack that might go into the space in the hatch. I am not sure the inner frame is strong enough to use as a backstop though. That is also an idea worth pursuing. I didn't spend a lot of time trying to get the lock into the hatch Saturday because the contortions were killing me. I hope to look at it closer this coming weekend

-

Home Built Z 'Full video build'

Dude! How did you end up with my old chevy??? Mine looked about like that with one shock replaced with baling wire. When we brought it home I coated my wifes windshield with oil blow by Apologies for the side track Jeff Jeff can you source a truck like that in Aussie land? They are getting more expensive here, much less there

-

Pan Shaping // Cutting Approach

If you do the lap seams at the back of the pan and the original pan is on the bottom, you will need to be sure and seam seal it really well or that joint will pick up water. I like to butt weld the tunnel side and I would probably butt weld the front too. I believe there was originally a lap weld some where near the rear of the pan but I am not positive on that. I like to make my repairs as invisible as possible. I believe the less the car looks like a patch work quilt the better value it will have.

- [SOLD] 1971 240Z Original Restoration, 918 Orange - BAT

Subscriber

Subscriber