-

Where to go with this rusthole

Alright ghys I'm now officially into the world of unkown haha. Panel fit up and the beginnings of body work. Drivers door is pretty good but the passnger door/fender is odd, the fender from PO is not straight down the edge vertical with the door, you'll see what I mean in the pics. I will shim the door out a bit to the side to mate up nice with the fender but what to do about the door gap. I can't do a lot more in terms of alignment with the door itself. I mean I could but I'll have to gri d and weld the lip at the back I think.... What's your guys thoughts on this bit of muckery I gotta put the latch on too. Before I finish working this should I be checking how it closes and fits with the wetaher strip on or just do my gaps and ensure it all lines up nice then epoxy er up! Sent from my SM-N960W using Tapatalk

-

Where to go with this rusthole

Holy hell boys! Been awhile , update is..... All rust is removed and repaired. Epoxied the bttm and seam sealed er up and today I put on the final 2nd coat of undercoating (herculiner) I chose this stuff because I had used it on my bro co and I a used that thing hard in the bush, she held strong so I assume in this application under a car instead of a beast she will hold up fine. Pretty friggen excited to bolt on a few suspension pieces and get this thing off the stand and on ots wheels. Next up is a bit of a break from it, then set and adjust door gaps and hood /tailgate stuff. Should be ready to epoxy the body and start in on skim coats of bondo by the fall. Yay! Sent from my SM-N960W using Tapatalk

-

Where to go with this rusthole

I've been a poor datsun builder . I grabbed a new toy and it's distracted me. I have however gotten the drivers quarter mostly welded up. Few more hours of messing around and body metal work is done! Just need to asses the rear valance and one bumper mount. Sent from my SM-N960W using Tapatalk

-

70 240Z wtf is this

I'd say it's a half arse dog leg patch panel install. The inner rocker under that is probably pooched unless they tackled it too. But judging by the fit up.... Probably not Sent from my SM-N960W using Tapatalk

-

Where to go with this rusthole

When I had the fender on the gap up front is about as large as I would want it to be so moving the door backwards isn't really an option. I'm going to get the quarter finished off and then finalize the bottom. I'd like to get it off the rotisserie and onto its wheels. Then I will focus on fine tuning panel fitment. Thanks for the info on welding rod. I really only need it at that top pointed area of the rear of the door Sent from my SM-N960W using Tapatalk

-

Where to go with this rusthole

Finally. There's a crappy gap up near the door handle. This is due to the repairs made before I got the car and full new quarter was installed. Nothing I can do to fix it with my quarter. I think I'll weld on a small piece of rod the the door edge and straighten the gap. Sent from my SM-N960W using Tapatalk

-

Where to go with this rusthole

Been awhile, I installed my subframe connectors. I have to fill a couple holes on the floor still. Then I can focus on quarters and inner fenders. Once those inner are done I can finally paint the bottom and get it off the rotisserie. Factory sway bar connectors are a no go now. I'll look into the ones that come with plates for the lower diff bracket. Any ideas on decent brands or kits for front and rear matched bars? Sent from my SM-N960W using Tapatalk

-

Where to go with this rusthole

you guys are awesome. I honestly hadn't even thought of a busted stud there just a buggered hole. I'll pull the intake and get the gasket out the way. Have a good look at er. I have an oxy acetylene torch so we're good there. Sent from my SM-N950W using Tapatalk

-

Where to go with this rusthole

Hey guys, couple questions on the motor. Pulled the exhaust manifold because one of the drpnt holes is pooched so im goin to asses if it's repairable or needs helicoil. Noticed front driverside engine has a hole on the block, un threaded, whats it for? Also a rear one threaded looks like it goes into the water jacket. Is that a coolant hookup when it in car? Thanks guys Sent from my SM-N950W using Tapatalk

-

Where to go with this rusthole

That's what i figured too, gives it the rigidity. I'll make er happen as per stock and drill whatever size holes I need when the time comes Sent from my SM-N950W using Tapatalk

-

Where to go with this rusthole

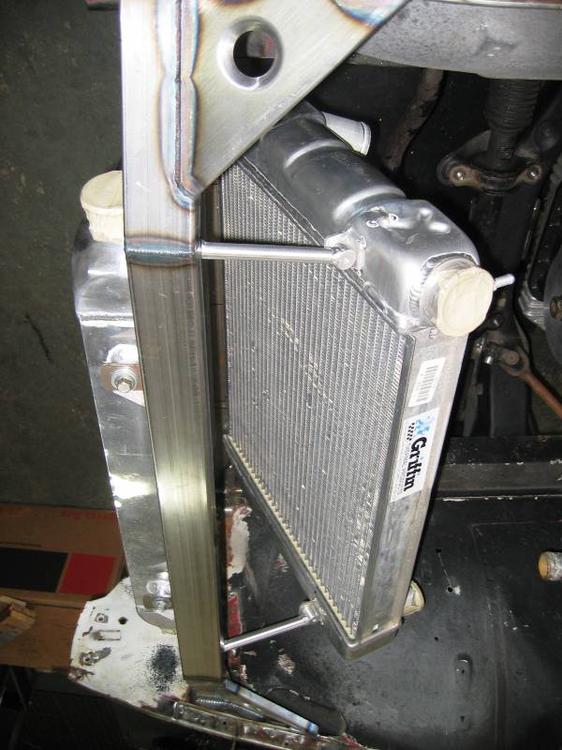

One off custom cardboard rad supports! We'll I hung both fenders and checked fitment of the hood and shes tight Its good at the firewall end but sometime through all this the front wi g's have tightened up with welding I guess. I made a rig with my. Bottle jack and spread it the 1/2 inch it needs to have good gap all the way through. I cut a spacer bar to hold it where I want it, measured and designed the upper support. I'll fab that either tonight or tomorrow and install it. Should be fine, how important do you guys feel the "webbing" is... The sheetmetal that goes from one side to the other accross the front that has holes in it for wire and air etc. (see second last pic, part that the guys has patched up) i am for sure adding the corner brace up top to fender wall, and am contemplating doing a similar triangle gusset downwards rather than form a hunk of sheetmetal in there. Similar to custom job attached. (last pic) Sent from my SM-N950W using Tapatalk

-

Where to go with this rusthole

One side looks kinda like a car! Almost done on the driver side.... Hey for the doors. Are there shims to push the top out from the a pillar a little? Shes pretty good laterall6and front to back but it could use some upper front corner out action haha. Sent from my SM-N950W using Tapatalk

-

Where to go with this rusthole

Thanks guys. I've gotta hammer form one more piece on the corner of the door. On that funny shaped corner at the back of the frame. Should be fun hahh, I did up a list of things still needed to address on the chassis and I'm further away than I thought. Ahhhh it never ends. Might take a couple weeks break. Sent from my SM-N950W using Tapatalk

-

Where to go with this rusthole

Ahh ok, passenger door only has 2 smaller holes... Power adjustable and defrost built into to driverside haha Sent from my SM-N950W using Tapatalk

-

Where to go with this rusthole

Well after some more beating and work with a torch, I have the door to a satisfactory level of tin bashin and no more oil canning. Im confident that the amount of filler ill need to make it straight won't be excessive and I'll still be able to maintain the body lines! Doors are now rust free but I want to figure this out. Mirror mount, the passenger door has 2 holes about 3" apart. The drivers door clearly has been messed with and I assume the big hole is an after thought. I want to cut some little circles to fill the holes but which holes do I keep? Any one have specs on various mirror mounts, spacing. I was tempted to run fender mirrors but that's in the future and I hear they suck. Can u guys fire me off an average that I can use for my holes? Or should I weld em all up and re drill whenever I get my hand on some mirrors. Sent from my SM-N950W using Tapatalk

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.