Everything posted by Zed Head

-

My Rockers seem to be a little off, or I'm off my Rocker(s)

No offense, but this is a classic case of cognitive bias. You're planning to "fix" what looks bad, but isn't measurably bad. The pits might actually hold oil for better lubrication. Anybody ever seen cracked big ends on connecting rods? They look broken. https://www.eeuroparts.com/blog/1939/engine-might-cracked-connecting-rods/

-

My Rockers seem to be a little off, or I'm off my Rocker(s)

If there are no grooves or low points on the "good" metal then the pits are really just a cosmetic issue. Function versus appearance. You might create a bunch of extra work and future problems by "fixing" the pits. Did you measure lash before removal? It would have increased if you had wear problems. An alternative view.

-

280z Starting help

Well then you don't have to worry about the ballast resistor. Turn on the key and measure voltage at the coil. Either terminal will do.

-

Battery arc'd and shorted, is alternator now toast?

Thought that "don"t run the engine with the bad parts in it" would come through the comments, but, just in case...don't run the engine with the bad parts. Actual voltage is probably higher if you're just reading the highest number on the gauge. You might be damaging more stuff. And the speedometer is mechanical. So any twitchiness there is not from an electrical problem.

-

Electric Fuel Pump Install

Your 240Z? Where did you get an oil pressure switch?

-

280z Starting help

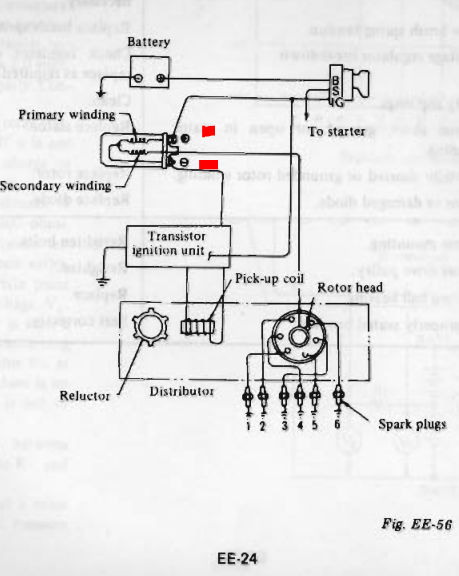

If your last coil really was a dead short then it might have fried your ignition module. Have you confirmed that the coil has power? And tested the pickup coil in the distributor? And that the coil is connected to the ignition module? There's a lost more to testing the ignition system than measuring coil resistance. Did you use a meter or a test light on the coil? Might be that the coil was fine. What year 280Z?

-

Injector Identification

You'd need to know the fluid they used also. Could be that they were only testing for consistency, like a cylinder pressure test. It's NAPA, not a business specializing in injectors. Don't make something from nothing, unless you're looking for things to do. If they're flowing 100 instead of 188, the car will be undriveable.

- 78 280z Severe Driving Problems

-

Injector Identification

They're common auto store replacements. The flow rates need to have a pressure associated with them to know what the rates mean. The fact they're all the same and that somebody bought them for your car suggests that they're probably fine. You'll know by how the engine runs if you have problem.

-

Too Good to Be True? – 125 Amp Bolt in Alternator @ Datsun Store

Pending failure. You could probably get it to work. Zspecialites could have designed his to work.

-

alternator rebuilding-78 280Z

I have a Bosch reman and it came with a label that said every electrical part was tested and if it met specs it was reused. They're generally poorly reman'ed. Lots of failures soon after buying. An attempt at a rebuild would be interesting. Has yours failed or are you planning ahead?

-

Tempted on removing, cleaning and reinstalling hitachi original distributor on my 240z

It's not a bad video, it does show how the parts fit. The locking plate on your 240Z will be slightly different but the basics are the same. You don't need to slather on all of that silicone sealant. Just use the gasket.

-

2+2 gets some SEMA love

From what I remember the car never sold. It was on eBay but they ended the sale. I think they thought it was worth $80,000. Then it was on the Gas Monkey site as For Sale but nothing happened if you clicked. Maybe they burned it for the show.

-

78 280z Severe Driving Problems

His video in Post #26 kind of sums it up, it's not really drivable. And in some of the others, #74 for example, he reports 42 psi with just the pump running, his injector flow test. Several odd things going on. Still haven't confirmed that the gauge is good. Several simple things could be knocked out to make the overall situation more clear.

- 78 280z Severe Driving Problems

-

78 280z Severe Driving Problems

Take the FPR out of the picture. Connect the fuel rail supply line to the fuel return line, with the gauge plumbed in. Run the pump. If you don't have pressure then it's not the pump. It might be the FPR. Or a restriction in the rail. Bypass the FPR on the rail and run another test. Break the system down in to its parts and something will show up. Hopefully, eventually, as you're working on the individual sub-systems you'll have a realization about something that's not right. You've kind of gone past the original finding that swapping injector connectors had no affect. Which might have been a clue that you had some injectors not opening completely. Which might be supported by the varying flow rates at wide open. One or two might be gummed up. I have my old BWD injectors from OReilly Auto with 10,000 miles on them. Kind of waiting to see what your plan is. Did you contact the rebuild guys? Seems like they owe you something. Maybe they have a couple of injectors that they can give you to make up for the bad ones they said were reconditioned.

-

Tempted on removing, cleaning and reinstalling hitachi original distributor on my 240z

It might crank but it will not run the same unless you have the marks matched, where the red arrow is. That is your timing adjustment. That's why there's an R and an A on that plate. Retarded and Advanced.

-

Battery arc'd and shorted, is alternator now toast?

Yes. The alternator works the same on the L28ET.

-

Battery arc'd and shorted, is alternator now toast?

Just saw that in his profile. One other possibility is that the S(ense) wire burned off when the positive cable shorted. There are unknown wires attached there. Check S at the alternator plug for battery voltage. Check fusible links also. It will be fun. Get a meter.

-

Battery arc'd and shorted, is alternator now toast?

Can't tell if you have an external regulator or internal. Or an ammeter or voltmeter. But, voltage should not jump to 16, ever. So, your regulator is shot, wherever it is. Don't know what you have in the car that beeps so hard to say on that. But whatever it is it probably wasn't designed for 16 volts. I'd fix that regulator first and see where you're at.

-

Is my coilover spring rate too high?

Do you know how much travel you have, and where the the travel is at ride height? Are you saying that the front suspension handles the speed bumps well but the back doesn't? Seems like you could do some simple inspection and comparison to understand your problem better. If I read your posts right it sounds like nothing has really changed. Might be time to stop and study.

-

Is my coilover spring rate too high?

Good that you're confirming. I learned something. I don't think that changing them from the top would have changed your alignment though. Slamming your head in to the roof would be from your shock damping, probably, not the springs.

-

Tempted on removing, cleaning and reinstalling hitachi original distributor on my 240z

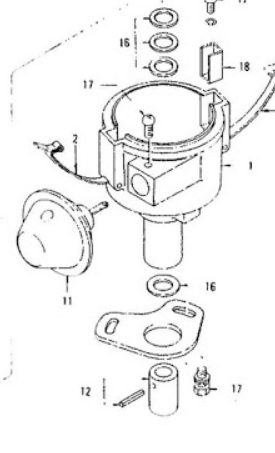

Note where the lines are in the spot with the red arrow. That's what they are for. Remove the circled bolt. Pull the distributor out. The o-ring will be right there. Then remove the two bolts that hold the pedestal. The gasket will be there.

-

Tempted on removing, cleaning and reinstalling hitachi original distributor on my 240z

Mark the distributor here, remove the screw on the other side, pull the distributor straight up. Not the screw pointing upward, but the screw you can see from the top.

-

Tempted on removing, cleaning and reinstalling hitachi original distributor on my 240z