Zed Head

Free Member

-

Joined

-

Last visited

-

Currently

Viewing Topic: L20a Engine Help

Everything posted by Zed Head

-

75 280 thermostat cover and housing

@zKars apparently has a big collection of parts.

-

5 speed worn bushing prevents reverse?

@Dave WM and @EuroDat and others have rebuilt their transmissions. Might have some ideas. Here's a good site for browsing parts. Better exploded diagrams than the FSM. http://www.carpartsmanual.com/datsun/Z-1969-1978/power-train

-

5 speed worn bushing prevents reverse?

It's odd that it gets stuck in reverse. Sounds the shifting rod is binding. There's no bushing that needs "pushing" in with tools. There are are two plastic bushings, one on the end of the shifter and one (two piece) bushing at the shifter's pivot point. Take a picture of your shifter and the bushings, we'll see how worn they are.

-

5 speed worn bushing prevents reverse?

Did you try it with the front case off? Just the forks and shifting rods? Separate the potential causes.

-

Camshaft locating plate

A used one would be fine. Any idea on how the plate broke? @borini63 sells parts, he might have something. Shipping should be cheap.

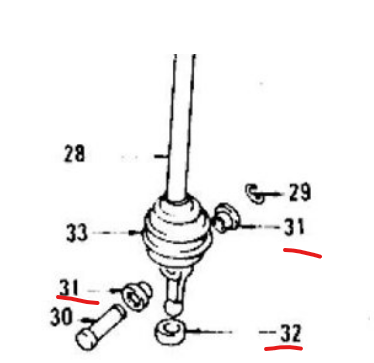

- 280Z Cv axle conversion-

-

R200 Comparison

Here are some flanges. Not sure he has stock though, he makes them in batches. http://www.chequeredflagracing.net/Datsun.html

-

R200 Comparison

Oops. not the right part. You need the flange, not the axle. The u-joint axles are plenty strong.

-

R200 Comparison

Here is a bolt on for Porsche 930 style CV axles https://zcardepot.com/collections/rear-axle-and-differential/products/billet-aluminum-cv-axle-adaptor-930-240z-260z-280z

-

R200 Comparison

Here Here's a weld-on conversion for the 300ZX CV axles. https://zcardepot.com/products/cv-axle-conversion-kit-r200-240z-260z-280z

-

R200 Comparison

I've only seen weld-on CV conversions that were any good. And that's for bolting them to the wheel-side axle. R200's are all clip-in on the diff side. The clip is either on the axle or in the diff, but they work the same way. No offense but you're asking questions that can't be answered because that's not how the R200 works. Did you look in the hole yet, for the clips? Your diffs are probably essentially identical. You can also pop the axles out of the one diff and try them in the other. Use a chisel or big screwdriver to pop them out.

-

R200 Comparison

You're right, I screwed that up. I even spent some time looking around to make sure it was right and it still wasn't. I think I had CV axles and viscous and short nose all blended together in my head.

-

280z 78 Wont idle, Running Rich, out of ideas.

Ouch. You can move the crankshaft by putting the car in high gear and rolling it. Future reference...

-

280z 78 Wont idle, Running Rich, out of ideas.

You might be getting cam timing confused with ignition timing. It's a common misconception. You groove and notch have nothing to do with ignition timing. You should confirm that the ignition timing mark is at zero when the #1 piston is at TDC of the compression stroke. That's the starting point for ignition timing. Not uncommon for the marks on the damper to be in the wrong place. Could be a bad damper.

-

R200 conversion using Whitehead Mustache Bar

The aluminum bars are thicker than the steel Nissan bars. You probably just need new longer studs to do it "right". Here is Arizona Z Cars bar. http://www.arizonazcar.com/diffmount.html

-

R200 conversion using Whitehead Mustache Bar

what year is your car? The more details the better, In general.

-

R200 conversion using Whitehead Mustache Bar

Pictures would still be good. The washers in the picture I posted look flat. Is there a gap between the mustache bar and the diff when the front diff mount is bolted up? It would be goofy to keep making the bars if they're not right, then add washers to shim it. Maybe you got a mistake. You can remove the studs and get longer ones. I hate to say it again, but Whitehead's explanation is goofy. He could have made the bar to fit properly, "stress-free". Not sure what he's doing with his special washers. Includes WHP exclusive diff mounting washers to properly mount diff with no stress or tension on the Mustache Bar unlike other designs. Billet 6061 Aluminum – excellent strength Uses standard Urethane Mustache Bar Bushings in choice of black or red bushings WHP Mustache Bar comes pre-assembled with all hardware included (diff mounting nuts excepted) All hardware is either plated or stainless steel Includes WHP diff mounting washers Easily Installed and Removed Bolt-On solution for mounting an R200 diff Includes WHP diff mounting washers

-

R200 conversion using Whitehead Mustache Bar

There are two types of hole and two types of washer and two types of stud. Need details. https://whiteheadperformance.com/product/whp-billet-aluminum-r200-mustache-bar-datsun-240z-260z-280z/

-

R200 Comparison

Nissan went to the short nose R200 in 1985, when they went to the rounder 300ZX body shape. And the DAT-110-300ZX pattern shown in the picture was also used for one 280Z year, in the 1975 280Z. The fact that the axle shafts are gone could be for several reasons. Somebody could have taken them to use in a diff that came with CV half shafts. Look down the axle holes and see if the retainer circlips are inside. If they are it might be a 75 diff. If they aren't it's probably an 85 or beyond. They'll both work in your car but the one with the axle shafts is probably easiest to get in there. I don't think the ring set alone is really worth much, except as garage art.

-

LS1 Coil packs

Megasquirt and Haltech are popular. You're kind of starting at the end. Pick your engine management system and fit the parts to it.

-

123 Ignition plasma ball

Be careful with disconnecting your plug wires. And sparks in general. My experience has been that electronic ignition modules do not like stray electricity. I fried a GM HEI module by leaving two wires disconnected by accident. http://newautoaa.blogspot.com/p/secondary-circuit-of-ignition-system.html

-

LS1 Coil packs

"coil packs" usually refers to wasted spark systems. The LS engine coils are "coil on plug" or COP. www.hybridz.org has a bunch about them. @madkaw has commented about them. Wasn't that you that started a thread in the recent past about this?

-

123 Ignition plasma ball

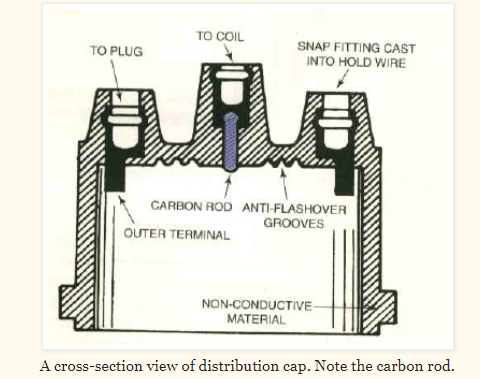

The spark would have to pass through the cap material, or along the surface of the cap, to get from the electrodes to the outside. A thin layer of nail polish is not likely to stop that. Is there carbon tracking inside the cap? Follow the path of the spark from the coil's center electrode, through the wire to the cap's center electrode, and then through the "button" inside and out the rotor to each spark plug electrode. The lowest resistance path will be used by the electricity, of course. It seems like bad cap material just based on the video. There are conductive paths on the outside of the cap, probably on the inside too.

-

Rockets from Iran hitting US bases in Iraq now

Nobody can say what's likely or unlikely these days. Not even worth trying to guess, just assume that somebody will suffer somewhere.

-

"The Orange"

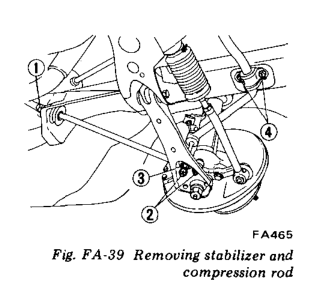

If you move the T/C rod through its normal motion while the suspension moves up and down you'll see that the rod pivots through the mounting hole where the bushings are. The end of the rod needs room to move up and down as the front of the rod moves. The PU bushings are solid and fill up the space that the rod end needs, putting a side load on the rod end. It fatigues and breaks off eventually. I think that it's also where the squeaking and groaning comes from.